2024 AIChE Annual Meeting

(569ev) Validation of Complex Low-Density Polyethylene Chemistry in a Plant-Scale CFD Reactor Model

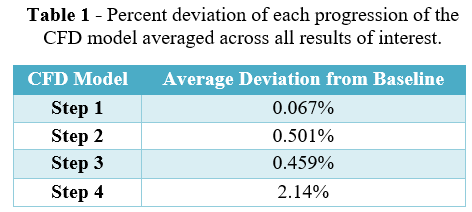

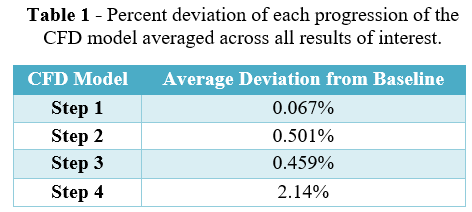

Simulation of chemical reactors has become popular for predicting the resulting polymer product properties. Many detailed polymer property simulation packages exist; however, they assume uniform mixing in the reactor, omitting many physical phenomena. Computational Fluid Dynamics (CFD) provides more insight into the nonhomogeneity of the polymer reaction path, as it can simulate non-ideal mixing in reactors. An autoclave Low-Density Polyethylene (LDPE) reactor was used to verify the implementation of the complex polymerization chemistry. The first three steps utilize a Continuous Stirred Tank Reactor (CSTR) that assumes complete mixing, where chemical complexity was progressively increased. The results were then compared to an industry-standard polymer software package that also assumes a homogeneous mixture. In the fourth step, the complex chemistry was incorporated into a plant-scale reactor model and the results were compared to the plant reactor. For the first three steps, the CFD model on average only differed from the industry-standard software by 0.067%, 0.501%, and 0.459%, respectively. In the fourth step, the CFD model differed from the plant reactor by only 2.14%. This verified CFD model will allow future studies on the influence of inlet conditions, stirrer geometry, variable material properties, and others on the end polymer properties.