In the global push towards decarbonization, the buildings sector is particularly well-positioned to contribute by offering many opportunities for deep electrification. Of existing thermal systems in residential buildings, water heating (traditionally powered by fossil fuels) currently accounts for about 20% of household energy consumption in the US. Electric water heaters have grown in popularity in recent years, comprising nearly 50% of existing US water heating systems; however, a majority of these units are electric resistance water heaters (ERWHs), which suffer from low efficiency, high energy consumption, and sometimes require an electrical panel upgrade, making electrification difficult in low-and-moderate income housing. Heat pump water heaters (HPWHs), another electrified alternative, use 60-70% less energy than ERWHs and can therefore often be installed without requiring panel upgrades. However, deployment of HPWHs has been hindered in space-constrained, low-income housing such as multifamily buildings or mobile/manufactured homes, as HPWHs tend to be significantly larger than traditional water heaters and cannot fit into the small utility closets often present in these settings. Currently, 32% of all housing in the US consists of multifamily or mobile homes, and of these units, over 60% have water heaters less than 50 gallons. Therefore, there is a need to develop smaller 30 – 40-gallon HPWHs with either equivalent or improved performance compared to larger electric or gas water heaters.

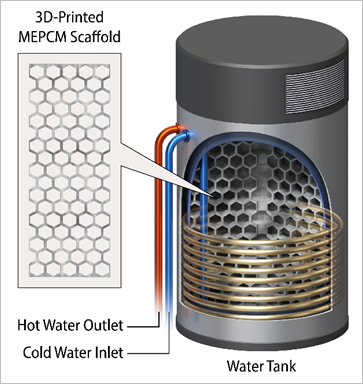

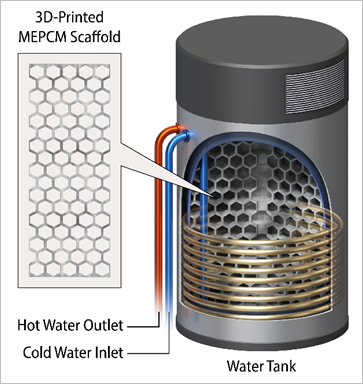

This presentation will first describe the overall need and efforts to incorporate thermal energy storage (TES) into small-volume HPWHs to meet space requirements in low-income housing while maintaining hot water requirements. A central part of the proposed solution is a novel phase change material (PCM)-integrated heat exchanger that increases the TES capacity of a HPWH, effectively allowing improved performance with smaller water tanks. The primary focus detailed here lies in the design development of a heat exchanger with thermal storage capabilities with respect to HPWH operation and associated water tank models. Using generative design and bio-inspired lattice geometries like triply periodic minimal surfaces such as gyroids, our efforts show great promise for enhancing heat transfer of the PCM heat exchanger, enabling rapid PCM charging and discharging that maximizes performance of small-volume HPWHs for low-income housing. When comparing a standard ERWH to a smaller HPWH that contains a PCM-integrated heat exchanger, preliminary results show that the latter system can overcome the heat storage capacity shortcomings of the ERWH tank with a heat exchanger comprising less than 10% of the HPWH tank volume. Our current modeling efforts show that a 40-gallon equivalent HPWH with 50% volume occupied by the PCM heat exchanger can at least double the heat storage and hot water delivery capabilities of an ERWH while maintaining low heat exchanger production costs.