Greenhouse gas (GHG) emissions reduction through carbon capture and storage (CCS) will be pivotal in achieving the world’s net zero emissions target by 2050. However, we have a long way to go before CCS is implemented at scale worldwide. Emerging technologies such as adsorption-based CO

2 capture have shown promise in treating flue gas streams with relatively high CO

2 partial pressures, such as those from the cement or steel industry. Despite their competitive advantages in energy efficiency in gas separation applications, they struggle to meet the scalability requirements compared to mature technologies like physical solvent absorption. In low CO

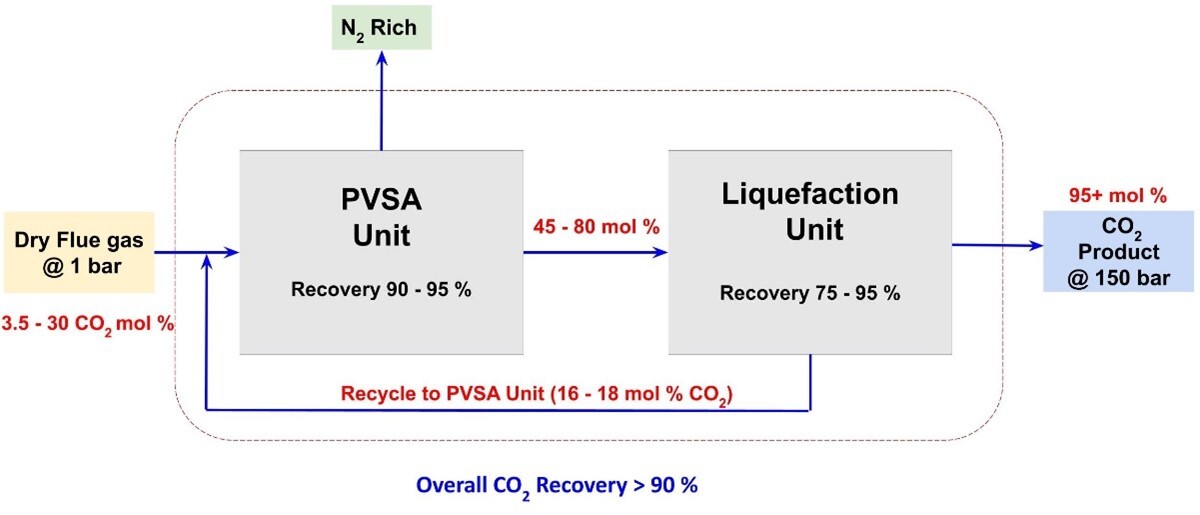

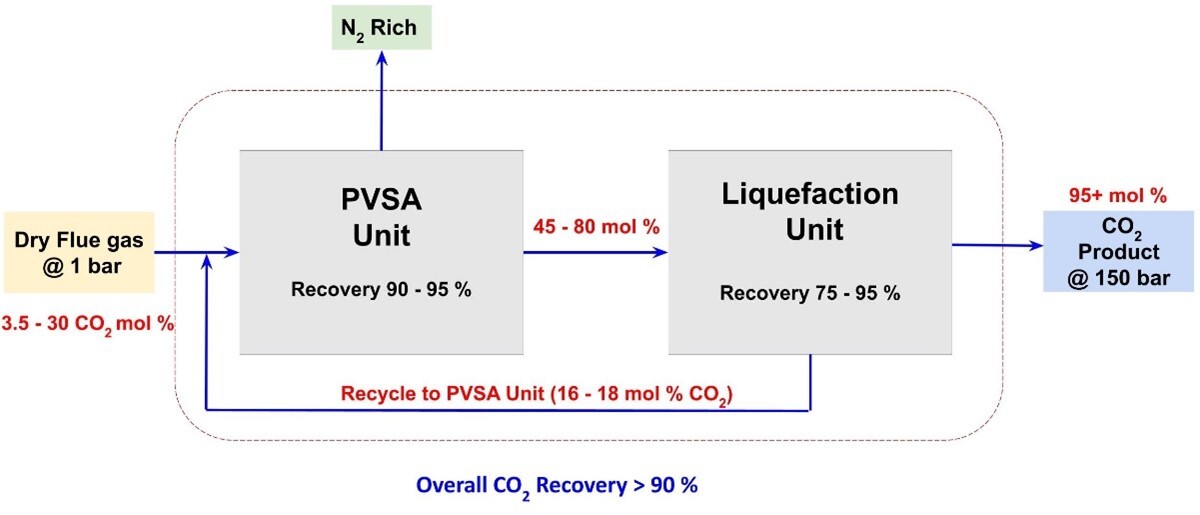

2 partial pressures, even with the best possible adsorbents, the capture costs for standalone pressure-vacuum swing adsorption (PVSA) processes are significantly higher than the Mono-ethanolamine (MEA) absorption-based processes. Hence, it is imperative to explore and evaluate scalable and economically viable alternative options, which is critical in determining the success of CCS in cutting emissions. This study aims to assess the effectiveness of a hybrid process that combines pressure-vacuum swing adsorption (PVSA) with liquefaction to determine if it is cost-effective and energy-efficient in capturing CO

2. Modelling and optimization studies are conducted for both processes independently to test the performance limits. The dynamic adsorption process is simulated using detailed first principles models consisting of a system of coupled partial differential equations of mass, heat and momentum transfer solved numerically in space and time. The liquefaction process is simulated using Aspen Plus

® from Aspen Technology, a commercial process simulation software using the Peng-Robinson (PR) thermodynamics property package. The hybrid process is optimized by minimizing the capture cost by constraining the recovery to at least 90 mol % of the CO

2 at a purity of 95 mol % from the overall process. The flue gas streams with CO

2 composition ranging from 3.5 - 30 mol %, representative of emissions from natural gas combined cycle (NGCC) power plants, coal-fired power plants, and cement and steel kilns, are studied. The variant of the PVSA process studied is a 4-step Light product pressurization (LPP) cycle. The performance of these processes for commercially available adsorbent materials like Zeolite 13X is studied. The liquefaction process uses compression and refrigeration to purify CO

2 up to 95 mol %. Artificial neural network (ANN) based machine learning models are developed to optimize the CO

2 avoided costs of the hybrid process holistically and determine the optimal intermediate CO

2 purity for varying feed CO2 compositions to the process. The hybrid process reduces the overall specific energy consumption and, thus, capital and operational costs by up to 40 % compared to a standalone PVSA process in the low CO

2 partial pressure ranges. It leverages the ability of the pressure vacuum swing adsorption process to recover CO

2 at a high rate in the low CO

2 partial pressure ranges. In contrast, the liquefaction process takes the load of purifying it from an intermediate purity of 40-75 mol % to the desired purity of 95 mol % to deliver it at conditions suitable for transport and storage. The hybrid process reduces the number of parallel PVSA trains required to process the same amount of flue gas, thus improving the scalability of the process. The hybrid approach emerges as a feasible and scalable solution by overcoming the limitations associated with standalone processes.