2024 AIChE Annual Meeting

(536f) Modeling of Fluidized Bed Sorption-Enhanced Biomass Gasification for Hydrogen Production Using Aspen Plus

Authors

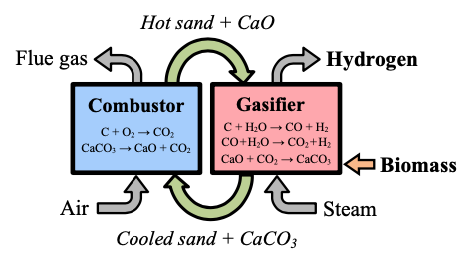

This study aims to create a comprehensive simulation that includes all stages of the SEG process, from biomass feedstock to steam gasification, limestone calcination, and transfer of the sorbents within a dual-fluidized bed configuration for CO2 sorption. By detailed modeling of the SEG process, this work seeks to optimize the operational parameters and enhance the hydrogen production efficiency. Considering the Department of Energy's Hydrogen Shot initiative, which targets a significant cost reduction for clean hydrogen, this detailed modeling effort aims to refine operational parameters for improved hydrogen yield and economic viability, thereby advancing the scalability of SEG technology.

The Aspen Plus simulation is developed in several key steps. The feedstock characteristics, including composition and moisture content, are defined based on typical biomass materials. The fluidized bed reactor within Aspen Plus is customized to reflect the specific conditions and reactions, including sorbents for in situ CO2 capture. This will involve incorporating kinetic models derived from lab-scale data to represent the gasification of biomass and sorption reactions of limestone. The simulation will also include sensitivity analysis to explore the impact of various operational parameters (e.g., temperature, pressure, feedstock, and solid circulation rate) on the efficiency of hydrogen production and the overall system performance.

The Aspen Plus model overviews the SEG process, identifying key factors influencing hydrogen yield, purity, and production cost. The simulation will identify optimal operational conditions that maximize hydrogen production efficiency while minimizing energy and material inputs. The sensitivity analysis is anticipated to highlight critical process parameters that significantly impact system performance, offering pathways for process optimization. This modeling effort will conclude recommendations for process design and operational strategies that enhance the scale-up application of hydrogen production through SEG.

Building on this modeling work, future research will explore advanced simulation techniques to incorporate dynamic process control and real-time optimization capabilities. The experimental data from the 200 kW pilot scale dual-fluidized bed system at the University of Utah will be used for model validation. Additionally, extending the model to include life cycle analysis and environmental impact assessment will provide a comprehensive evaluation of the sustainability of the SEG process. Ultimately, this research will contribute to developing a robust, efficient, and economically competitive SEG process for hydrogen production, supporting the transition to a more sustainable energy system.