2024 AIChE Annual Meeting

(500b) Autothermal Sabatier Reactor for Biogas Conversion to Renewable Natural Gas: Design, Experimental Proof-of-Concept, and Parametric Study

Commercially available biogas upgrade technologies utilize adsorption, absorption, cryogenic, and membrane separation to upgrade biogas to high quality biomethane based on physical or chemical separation of CO2 followed by removal of additional impurities including water vapor, H2S, and siloxanes. Depending on the composition of biogas, significant portion of N2 and O2 can be removed via pressure swing adsorption (PSA) on molecular sieves or membrane separation. Despite the decent performance, high operation costs and large capital investment associated with the abovementioned technologies limit the economic viability of the biogas utilization on an industrial scale. New upgrade technologies such as biological methods are still under development. One of the biggest challenges of biological methanation is that it’s hard for water and gas phase to have sufficient contact due to low solubility of hydrogen in water.

An alternative way is direct methanation of biogas, which involves thermocatalytic conversion of CO2. Producing synthetic CH4 via the thermocatalytic conversion of CO2 involves Sabatier reaction, which is accompanied by reverse water gas shift and CO methanation. When using renewable (or low-carbon footprint) electricity to generate H2 via water electrolysis, the resulted synthetic CH4 can be considered as renewable natural gas (RNG). Thermocatalytic conversion of CO2 offers the benefits of fast reaction rates and high conversion efficiencies allowing for compact, high throughput operation. Also, direct CO2 methanation via the Sabatier reaction can eliminate the huge capital and operating cost of CO2 separation.

SUGGESTED SOLUTION

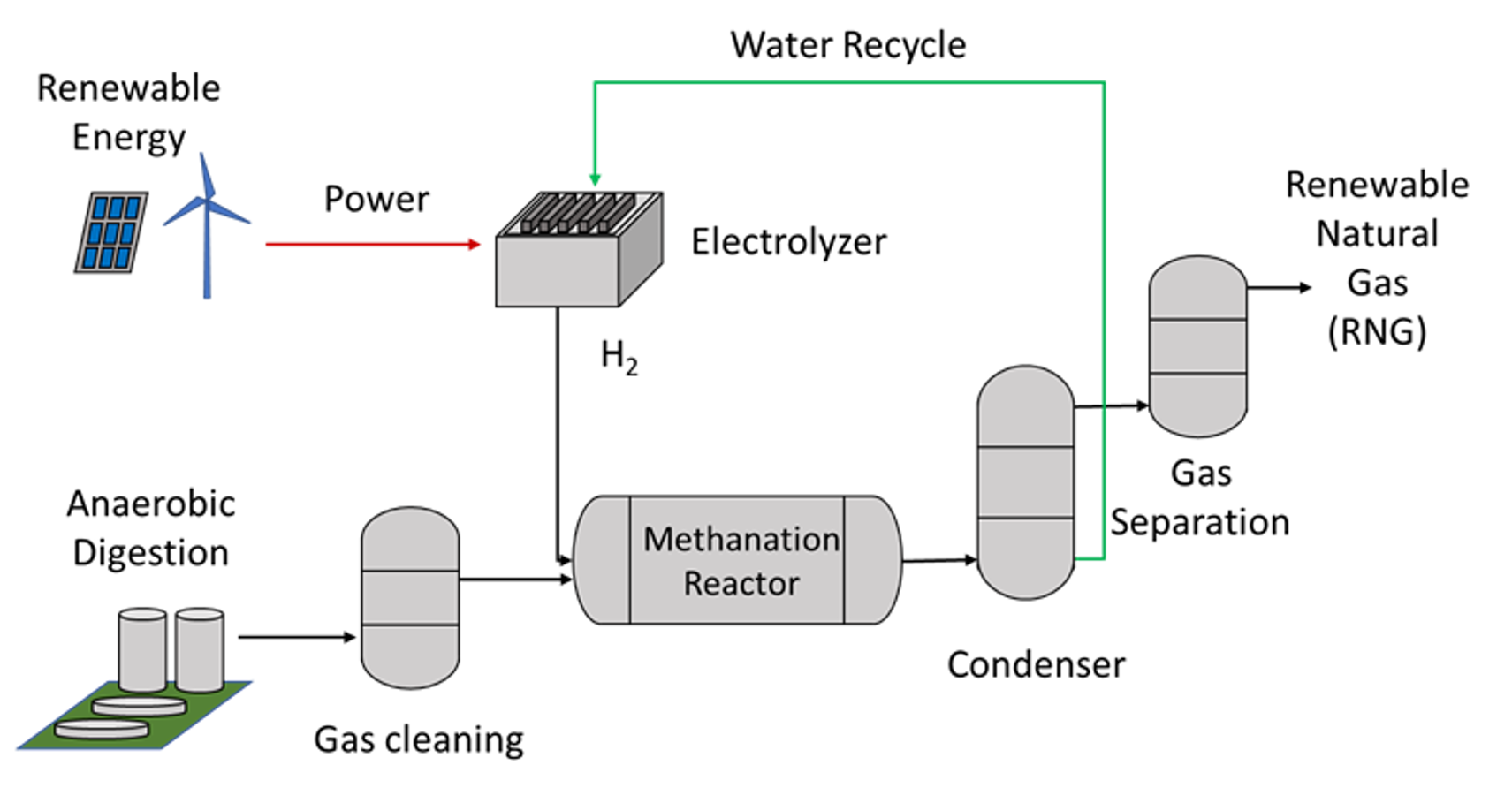

The suggested process of biogas direct upgrading is conceptually shown in the attached figure. H2 required for CO2 methanation can be obtained from water electrolysis powered by renewable or (low carbon footprint) surplus electricity, since the electrolysis consumes most of the electricity among all processes. A number of different gas cleanings solutions has been suggested and tested in recent years, such as adsorption on active carbon and other solid sorbents under ambient temperature to remove impurities such as H2S, VOCs and siloxanes. After the cleaning step, pretreated biogas is fed to the Sabatier reactor, e.g., packed bed. A pipeline grade RNG is obtained from the reactor outlet after water condensation and further product upgrading (removal of N2 and unreacted CO2 and H2), if required. Electrolysis, as well as all cleaning, condensation and upgrading stages are commercially available and the economic viability of the concept presented was recently assessed in our group, leading to positive conclusions. However, reactor design and catalysis still present significant technological challenges, mainly due to the significant heat of reaction from the reactor, which leads to sintering of catalyst as well as conversion limitation due to the thermodynamic equilibrium.

METHODOLOGY

In the study reported herein, a simple tube-and-shell design was adopted in order to investigate the possibility of the autothermal operation of a Sabatier reactor, i.e., standalone operation without any feed preheating or reactor heating. The reactor was made from stainless steel tubing using standard (Swagelok) connectors and a commercial Ni/Al2O3 catalyst. Nitrogen was used for cooling. Three prototypes were investigated with different sizes and configurations. It was demonstrated that, after the initial feed preheating for ignition, the reactor can be continuously operated as a standalone autothermal unit, achieving 91% CO2 conversion and 100% selectivity to CH4 generation using a synthetic biogas feed.

MAIN RESULTS

An air-cooled, autothermal Sabatier reactor was experimentally investigated using simulated biogas composition, analyzing the effects of feed temperature, space velocity, pressure, and cooling rate on the reactor performance in terms of CO2 conversion and selectivity to CH4 generation. The stainless steel, tube-and-shell reactor comprised a commercial Ni/Al2O3 catalyst in the shell compartment, with the inner tube being used for active cooling using compressed air. The performance of the commercial Ni/Al2O3 catalyst was first assessed with real raw biogas. Air-balanced synthetic biogas was found to be a good model system for reactor testing as a substitute for treated raw biogas (after H2S and VOC removal). All reactor prototypes were demonstrated to be able to operate autothermally using the air-balanced synthetic biogas as a feed. The final prototype achieved 91% CO2 conversion, while maintaining complete selectivity to CH4 for over 100 h at 3,100 L/(kg h) with stable reactor temperatures.

INNOVATION & SIGNIFICANCE

Our findings provide important general insights into operation of lab-scale Sabatier reactors. Due to the simplicity of assembly, such laboratory reactors are very useful for investigating effects of various operating parameters on reactor performance. Our study also provides a novel perspective on direct biogas upgrade, an approach that can potentially reduce RNG generation costs due to the elimination of CO2 separation, promoting biogas utilization. The experimental data collected in this study can be also used to calibrate a reactor model, which can be used for further scale-up (this work is underway and will be reported elsewhere).