2024 AIChE Annual Meeting

(4nf) Electrochemical Manufacturing of Valuable Liquid Fuels and Product Upgrading By CO2 Gas Reduction Reaction (CO2RR) and Reactor Design

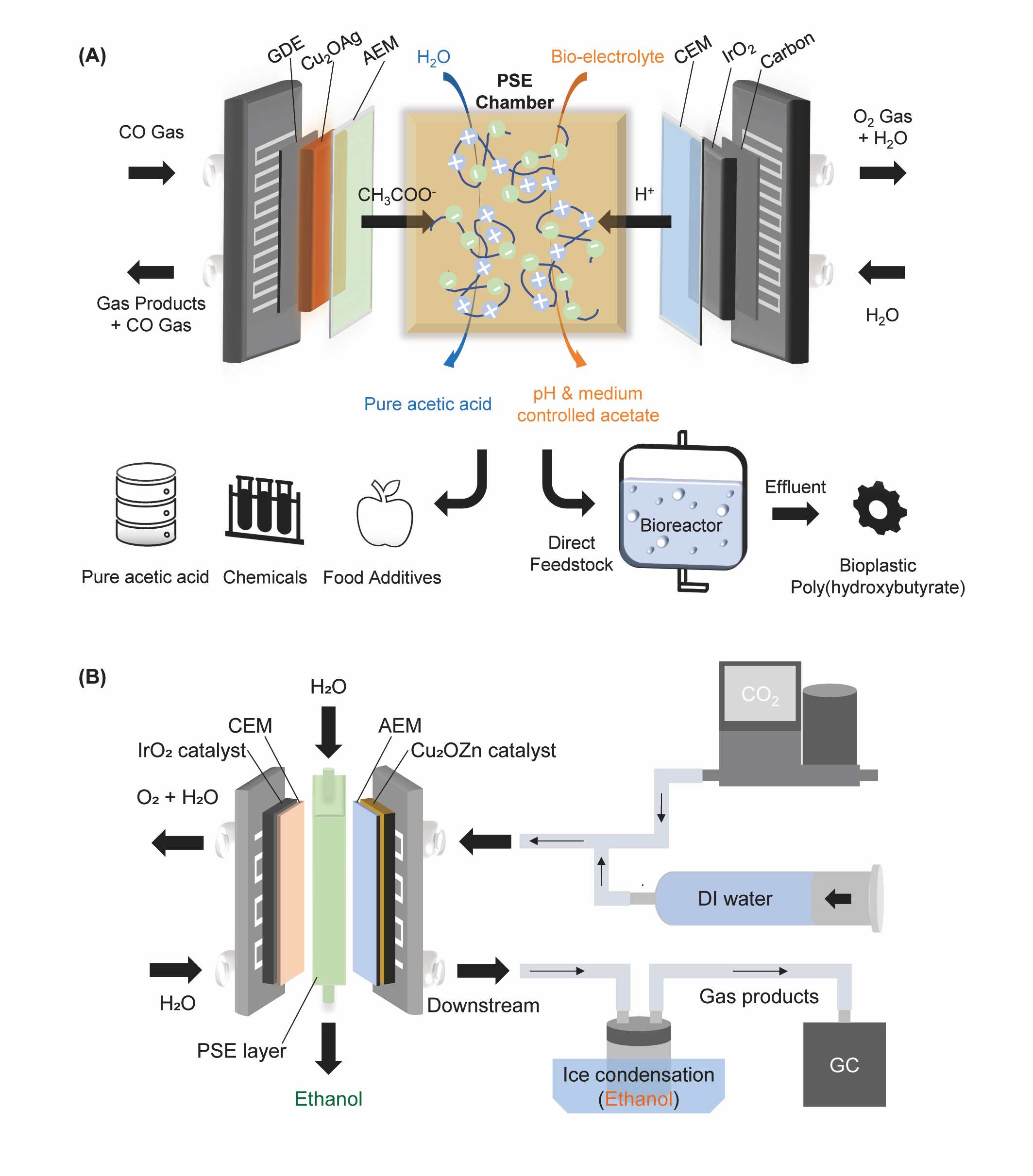

Herein, we developed a grain boundary-rich zinc-doped Cu2O electrocatalyst that presented high ethanol Faradaic efficiency of over 40 % under a current density of 350 mA·cm-2. Furthermore, we employed the developed catalyst in our porous solid electrolyte (PSE) reactor with careful salt management design to demonstrate the stable generation of high-purity ethanol solution directly from electrolysis. By co-flowing CO2 gas and DI water droplets with an optimized flow rate into the cathode side, we can facilitate the stable CO2RR under 250 mA·cm-2 while showing about 30 FE % of ethanol for 180 hours. Additionally, we demonstrated a PSE reactor producing highly selective and pure acetate coupled with the biosynthesis system to generate C4+ polyhydroxybutyrate (PHB) bioplastic. A silver-doped Cu2O nanocube electrocatalyst was carefully tuned for high selectivity towards acetate other than alcohols, which resulted in over 150 mM (with over 55 % Faradaic efficiency) of high-purity acetic acid product. With the optimized electrolyte, Ralstonia eutropha bacteria utilized the acetate and produced biomass with approximately 450 mg/L of C4+ poly-hydroxybutyrate bioplastic by digesting acetate in 4 days.

Figure Caption: (A) Schematic of a porous solid electrolyte (PSE) reactor with diverse product chains from electro-synthesized acetate. Continuous pure acetic acid and electrolytes for biosynthesis can be generated by flowing DI water and the optimized mineral salt medium through the middle layer, respectively. (B) Schematic of a salt-managing PSE reactor and the ethanol collecting procedure through the PSE layer chamber and cathode side downstream.

Research Interests: Energy Conversion, CO2 Reduction Reaction (CO2RR), Energy Storage Systems (ESSs), In-situ/Cryo TEM, Fundamental Mechanism Understanding

Research on energy conversion (i.e., Energy storage systems, CO2 electrocatalytic reduction) by the development of novel materials and systems + Understanding of fundamental reaction mechanisms using the In-situ/Cryogenic TEM technique. Fundamental understandings play critical roles in developing practical applications, ranging from renewable energy conversion and chemicals/fuels production in new energy systems.

Teaching Interests: Based on my background, I will teach knowledge from nanometer-scale material analysis for reaction mechanism studies to meter-scale electrochemical device engineering for practical development. This can provide scientific evidence for problem-solving approaches at the front line as future research leaders in diverse fields grow.