Breadcrumb

- Home

- Publications

- Proceedings

- 2024 AIChE Annual Meeting

- Sustainable Engineering Forum

- Design for a Circular Economy

- (46e) Enabling Circular Aquaculture with a Biofilm-Based Waste-to-Feed Biotechnology

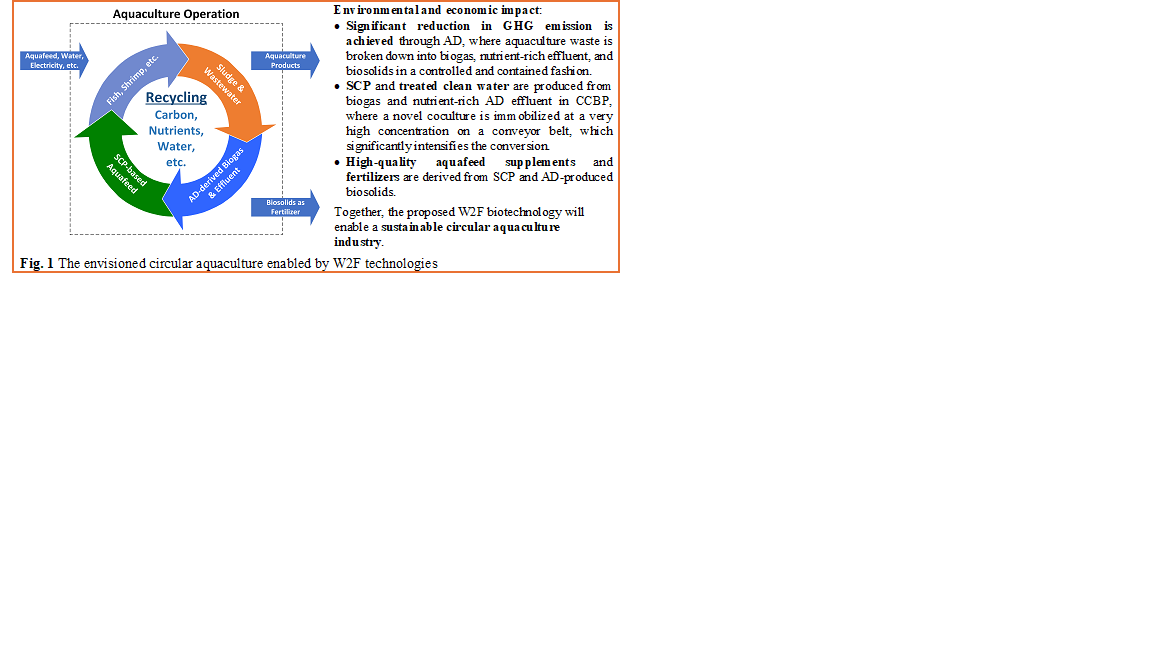

To achieve sustained aquaculture production, we propose a a novel, sustainable and profitable waste-to-feed (W2F) biotechnology to enable a circular aquaculture economy. As shown in Figure 1, the proposed W2F biotechnology integrates the commercially proven anaerobic digestion (AD) with a recently patented circulating coculture biofilm photobioreactor (CCBP) to convert aquaculture waste into single cell protein (SCP) as aquafeed supplements, treated clean water and fertilizer.

Although AD has many environmental and technical advantages over aquaponics and bioflocs technology, current AD-based waste-to-value (W2V) technologies have their own limitations. To date, the most prominent AD-based W2V technologies are: (1) combined heat and power (CHP) and (2) biomethane (BM) that utilize AD-generated biogas, and (3) microalgae cultivation utilizing AD-generated digestate (and CO2) for biofuels. None of these technologies have been proven economically feasible in the US due to several reasons. One is the low value of the products (electricity and natural gas); the other is the limited government incentives (compared to some European countries); finally, it is the high cost in treating contaminants in biogas. We hypothesize that if the AD-produced biogas and nutrient-rich AD effluent can be converted into a higher-value product with low operation cost, it will promote broad installations of AD, especially at small to mid-scale farms, and capture the enormous environmental benefits brought by AD.

In this talk, we will present our recent findings in the optimization of biogas production through co-digestion of fish sludge and food waste. Then we will present our recent progress in utilizing methanotroph-microalgae coculture biofilm to simultaneously convert AD-produced biogas and nutrient-rich AD effluent into microbial biomass, which will serve as the feedstock for SCP, a higher-value aquafeed supplement. We discuss how the proposed CCBP addresses the long-standing challenges of biological methane conversion (mass transfer of gas substrate with small solubility) and microalgae cultivation (mass transfer of gas substrate and light attenuation) by quantitative comparative studies.