Breadcrumb

- Home

- Publications

- Proceedings

- 2024 AIChE Annual Meeting

- Sustainable Engineering Forum

- Design for a Circular Economy

- (46d) Potential to Recover Copper from Electronic Waste and Implications for the Circular Economy

Copper is crucial to enable the transition to a decarbonized future This is largely due to its role in critical technologies and infrastructure. However, copper production is not without environmental, economic, and societal costs of its own. Typically, the most efficacious manner in which to reduce these burdens is by keeping already mined and refined copper in circulation. However, given the projected copper demands, due to continuing population and economic growth, there will be continued increasing requirements for primary metal production. Beyond that, some uses of copper such as copper containing pesticides are dissipative in nature, meaning that they are unable to cycled in the economy due to the nature and goals of their use. The environmental impact of mining virgin copper ranges from 5.34 to 7.33 kg of CO2e per kg of refined copper dependent on method, while recovered or secondary copper has an environmental impact of 1.58 kg of CO2e per kg of refined copper. Due to projected increases in the demand for copper it is estimated that the associated carbon footprint of copper will increase between 100%-200% between 2010 and 2050. However, depending on the quantity of copper, the nature of its use, and the matrix it is embedded in, it may not be environmentally nor economically advantageous to recover the copper. At the same time global copper reserves are currently estimated at 2.1 billion tons of copper, with an estimation of undiscovered resources at 3.5 billion tons. However, not all of this copper is easy to mine and refine. This work seeks to look to the history of copper consumption, largely in the US, in order to generate insight into future copper consumption and its sustainability implications. And to posit the idea of the greater potential of consumer electronic waste as one source of future copper and discuss the conditions under which this might occur.

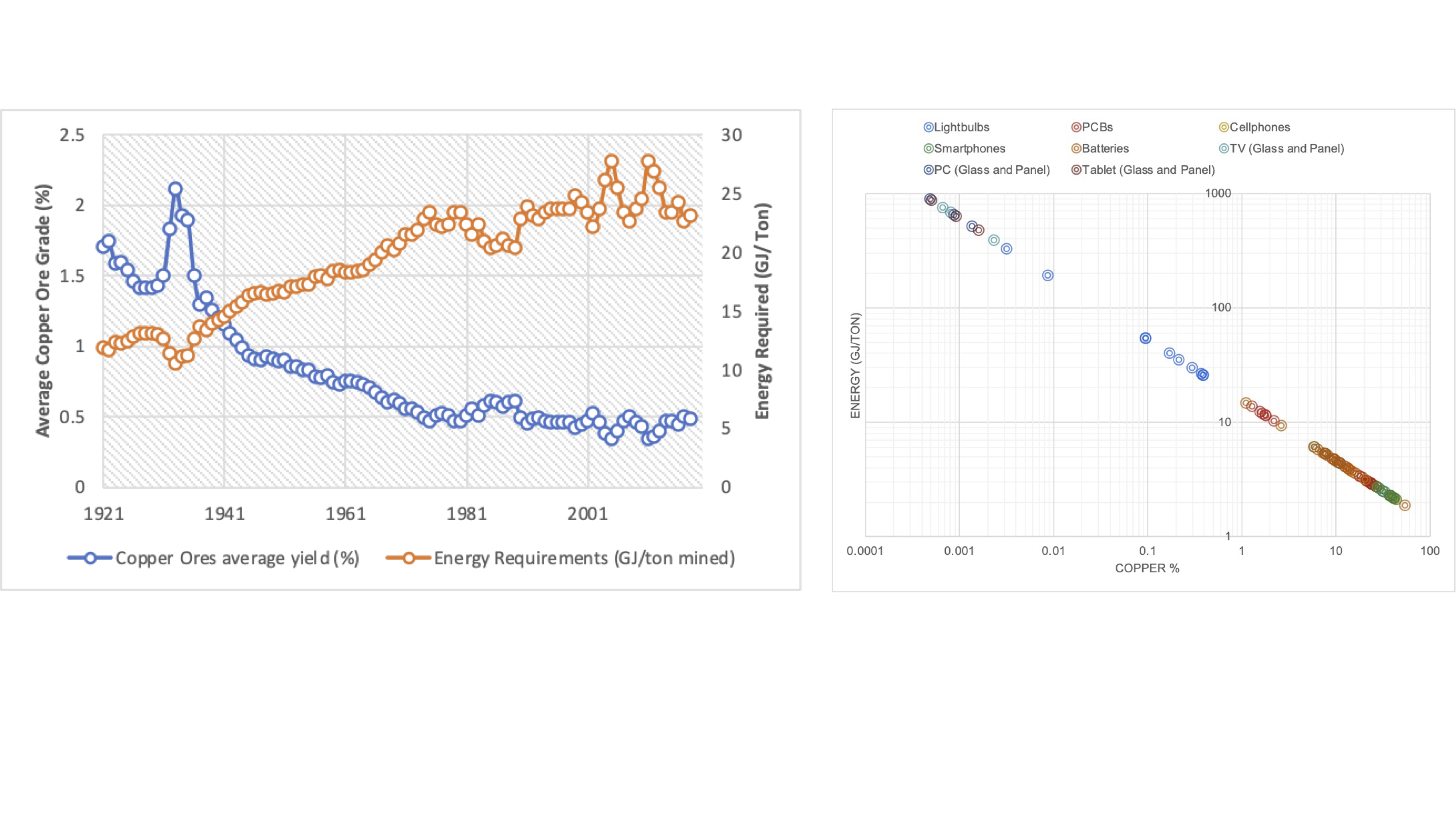

Methods: Historical copper data is mined from reports by the United States Geological Survey (USGS). It should be noted that the numbers differed or were later revised in some of the reports. And thus, there is some uncertainty around the exact numbers reported. In general, when this occurred the revised reported number was included in the data collected. If this was unclear, then the value presented with more precision was maintained. The real economic cost of copper is calculated from the cost as presented in the USGS reports. In particular using the London Price Average Cents per pound as reported. In some of the earliest price reports, the copper price is simply provided without further reference. Historical series data was used to convert the dollars values to 2022 equivalents or earlier years. The relationship between copper ore grade and the energy needed for the production of usage copper has been modeled previously considering ore grades and gross energy requirements. Where E, the gross energy requirement, is expressed in GJ/metric ton of mined copper as a function of the ore grade (% copper ore). This is applied to the average annual US ore grade obtained from the annual USGS reports. The same methodology was applied for the energy embodied in the copper e-waste. The data was adopted from published studies which characterized the quantity of copper in various e-wastes.

Results: The average primary copper ore produced in the US has decreased over the last century, which has also led to a corresponding increase in the energy required for mining and beneficiation facilities. As primary available ore grade continues to decrease and the energy required to make that ore into useful copper continues to correspondingly increase, the idea arises when the primary copper industry will run into the mineralogical barrier. This barrier as expressed by Skinner, and defined as when the rock would need to be pulled apart chemically in order to gain resources such as copper, instead of mining ore itself. It also introduces the question as to whether copper based waste which was not previously considered economically feasible to mine at different points in industry (such as tailings and e-waste containing copper), will become viable sources of copper feedstock. Essentially, when does the energy and corresponding environmental impacts of copper become costly enough where it is more environmentally efficient to mine old wastes?

Mining spent consumer electronic waste for resources is not a new idea. The figure presents the copper content, expressed in percent mass, of different small post-consumer electronics. And is compared with the energy embodied in the copper from mining and beneficiation when that same grade of ore would be mined from virgin stocks. This is not the energy required to recover the copper from these materials, as that has the potential for significant variability, but simply the minimum amount of energy would need to be spent if virgin ores of this same grade were mined . This is at best a significant simplification, however, it allows for the consideration of energy that would need to be spent to mine comparative virgin ores, and suggests that if the embodied energy cost is less than what is shown in the figure, that there is the potential for significant benefit if copper is recovered from spent electronics. As of 2018 the average copper ore processed in the US had a yield of 0.48%. This is significantly lower than what is available in several categories of spent electronics: batteries (12.98%±10.61%), smartphones (27.83±13.87%), cellphones (36.25%±6.52%) and sometimes printed circuit boards (PCB) (15.86±9.86%). This suggests some potential for considering spent electronics as a source of post-consumer secondary copper, in order to reaching increasing copper demands. Recent work by Zeng et al. found that in China recovering copper from spent urban electronics could be completed at economic costs that we at least comparable to those of virgin mining.

Conclusions: Post-consumer electronic waste is one potential source of copper to meet current demands as many electronics contain a higher mass percentage of copper than what is currently being mined. This suggests the potential for environmentally and economically beneficial copper recovery from waste electronics in order to meet current and future copper demands. Although challenges exist with respect to recovering the waste electronics from consumers and the copper along with other valuable metals. Washing machines are explored as an example for the potential of copper recovery.