The transportation sector is dominated by internal combustion engine vehicles (ICEVs) using gasoline, and therefore significantly contributes to greenhouse gas emissions. Meanwhile, battery electric vehicles (BEVs), the primary consumers of lithium, are expected to drive the global demand for lithium, leading to environmental and social issues. This scenario underscores the need for a shift towards more sustainable transportation options, such as fuel cell electric vehicles (FCEVs) and ICEVs running on sustainable fuels. A comprehensive framework is essential for evaluating conventional and emerging fuels and powertrain technologies, facilitating informed policy making for sustainable transportation infrastructure development. While existing studies often focus on a limited range of vehicle types and fail to incorporate multiple impact dimensions into a unified assessment, recent research employing a circular economy (CE) perspective by Baratsas et al, 2022, shows promise in providing a holistic comparison of different technologies [1,2]. This work broadens the scope of the previously developed Circular Economy (CE) assessment tool, known as MICRON [2], to include the evaluation of vehicle power train technologies. The CE assessment tool is aligned with five circular economy goals: i) minimizing waste and pollutants, ii) decreasing the utilization of natural resources, iii) boosting the proportion of renewable resources, iv) lowering emissions, and v) increasing the durability of products. This quantitative evaluation is based on the General Reporting Initiative (GRI) standards and Life Cycle Assessment (LCA) databases. The CE impact scores are calculated through a range of quantitative indicators associated with the five circular economy goals. An overall CE index is obtained by averaging each of these category-specific scores. The overall CE index ranges from 0 to 1, where 0 represents linear operations and 1, circular operations. In this work, MICRON was modified to better address the assessment of vehicle power trains, by including vehicle-specific indicators and metrics, including waste generated per km, water and energy consumed per km, and share of renewable material used to manufacture the vehicle’s powertrain. A levelized approach is implemented to account for both the operation and manufacturing of the vehicle, considering its entire lifetime.

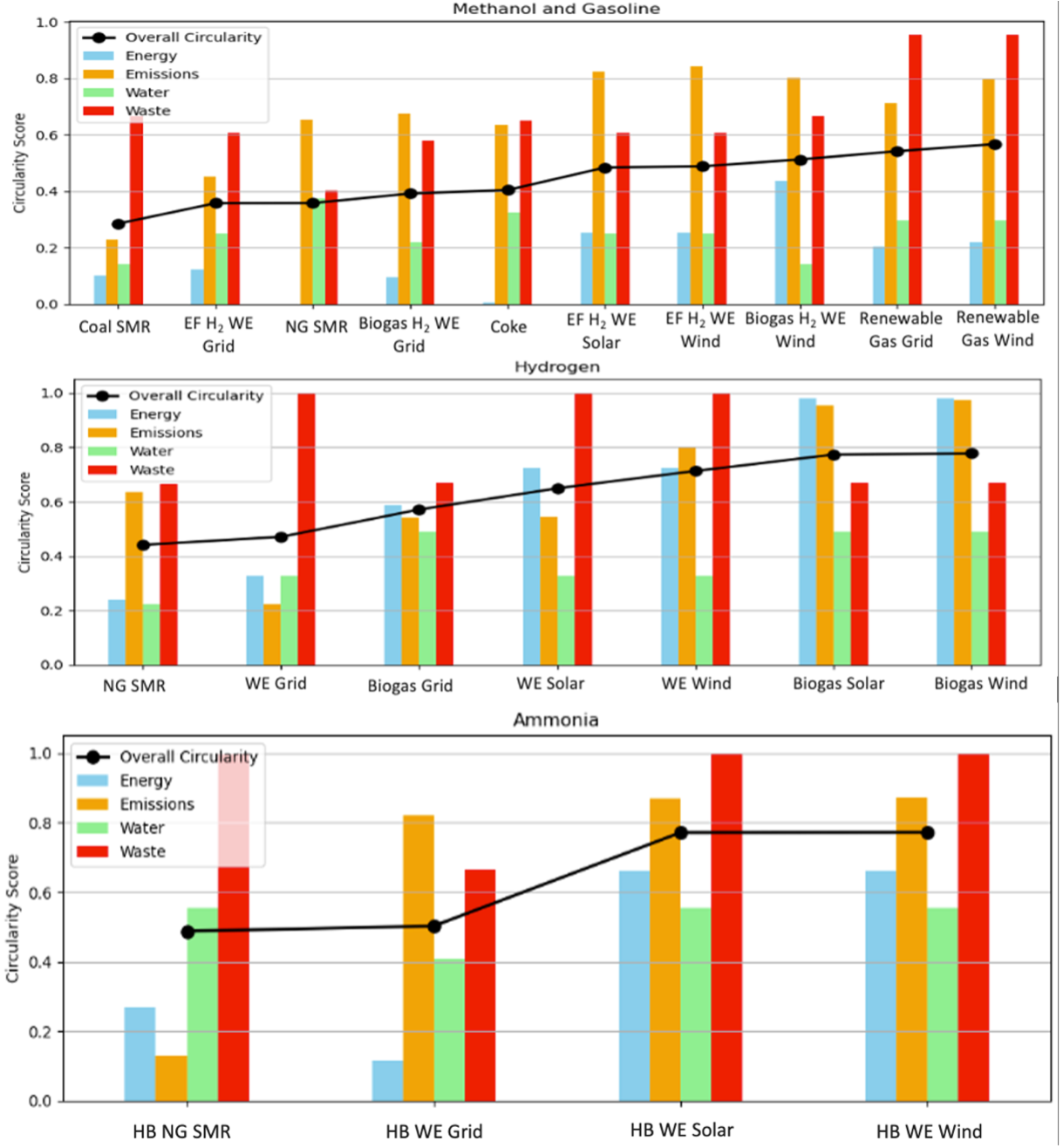

The updated MICRON tool is used to evaluate various vehicle powertrains, including hydrogen ICEVs, hydrogen FCEVs, methanol/gasoline ICEVs, BEVs, and gasoline ICEVs, focusing on the current and most promising fuel production pathways for each fuel. The nickel cobalt manganese (NCM) and Li-ion batteries are also considered for BEVs. Our initial circular assessments focused exclusively on the fuel production pathways and have revealed hydrogen from biogas as the most circular fuel, attributed to its low emissions and significant renewable energy share, as shown in Figure 1. For methanol, production using hydrogen from wind-powered water electrolysis and biogas stands out for its low emissions. Similarly, the Haber-Bosch process for ammonia production, powered by wind energy electrolysis, ranks highest in circularity due to efficient waste recycling and reduced emissions. Renewable gasoline also demonstrates high circularity, benefiting from its recyclability and the use of captured carbon in its production process. These findings emphasize the importance of transitioning to such circular technologies to achieve sustainable reductions in greenhouse gas emissions. The project has further expanded the MICRON framework to encompass the transportation and storage of these fuels, as well as their utilization in vehicles, providing a comprehensive circular metric of the vehicle’s entire life cycle. These results can help policymakers and stakeholders make informed decision-making to achieve sustainable transportation systems.

Figure 2. Circular economy indexes for each fuel production pathways [3-10]. 'NG' denotes natural gas, and 'SMR' refers to steam methane reforming. 'WE' indicates water electrolysis. 'HB' stands for the Haber-Bosch process. 'EF' represents ethanol fermentation, a bio-based production route.

References:

- Ahmed AA, et al. (2023) Sustainability. 15(1):171.

- Baratsas SG, et al. (2022) Comput. Chem. Eng. 160:107697.

- Mann M. et al. (2004) National Renewable Energy Lab., US Department of Energy.

- Hajjaji, N., et al. (2016) International Journal of Hydrogen Energy, 41 (14), pp.6064-6075.

- Spath P.L, et al. (2001) NREL/TP-570-27637, National Renewable Energy Laboratory

- Li, J. et al. (2018) Journal of Cleaner Production

- Matzen, M., et al. (2016) Journal of Cleaner Production

- Eggemann, L., et al. (2020) Journal of Cleaner Production, Volume 271

- Zupko, R., (2019) The International Journal of Life Cycle Assessment, Vol. 24, pp. 1793–1804

- Biçer, Y., et al (2017) Environmental Management, Vol. 59, pp. 842–855, 2017.