2024 AIChE Annual Meeting

(442g) New Process Integration of CO2 Capture and Utilization for the Ironmaking Process

Authors

Wei Wu - Presenter, Research Institute of Petroleum Processing, SINOPE

Po-Chih Kuo, National Cheng Kung University

Yin-Ping Wu, National Cheng Kung University

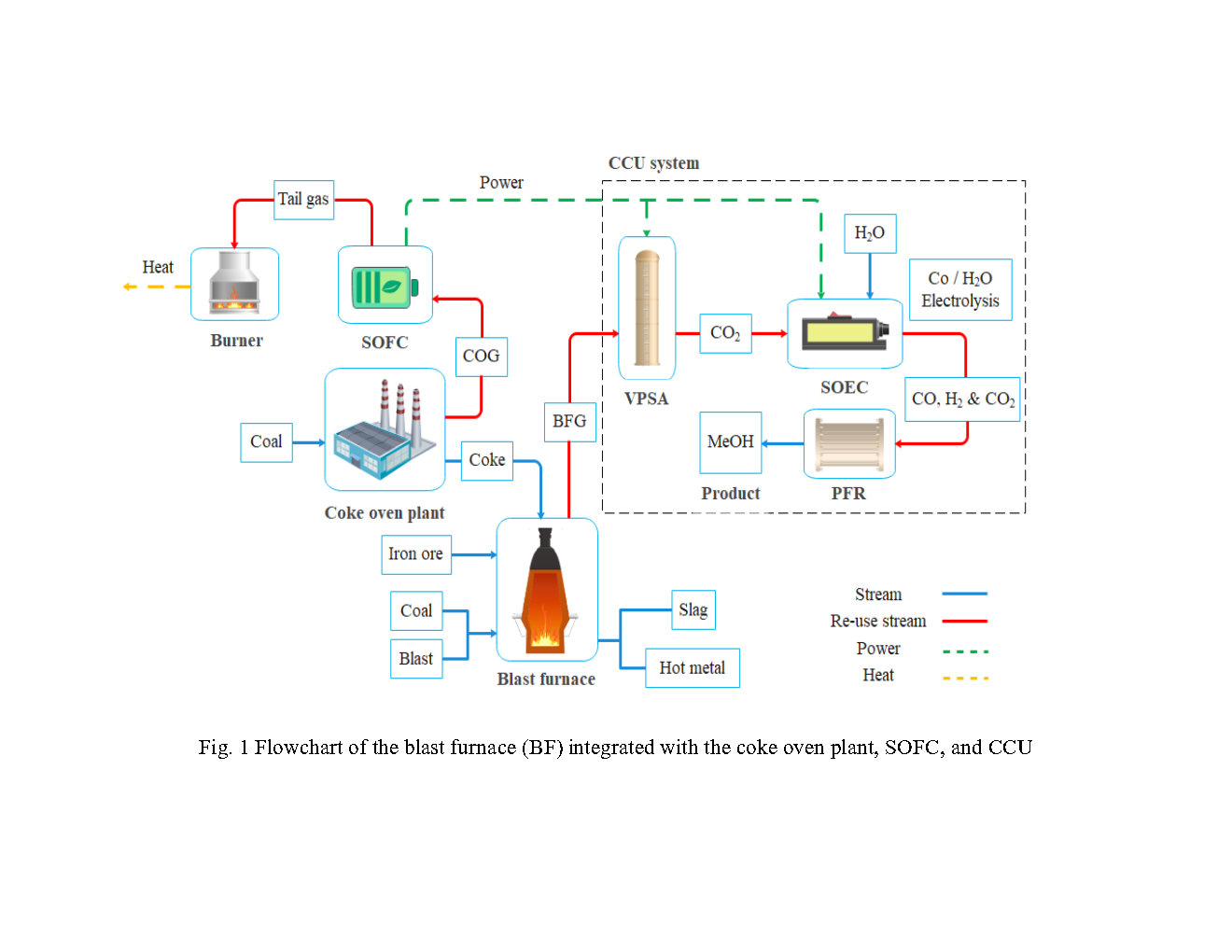

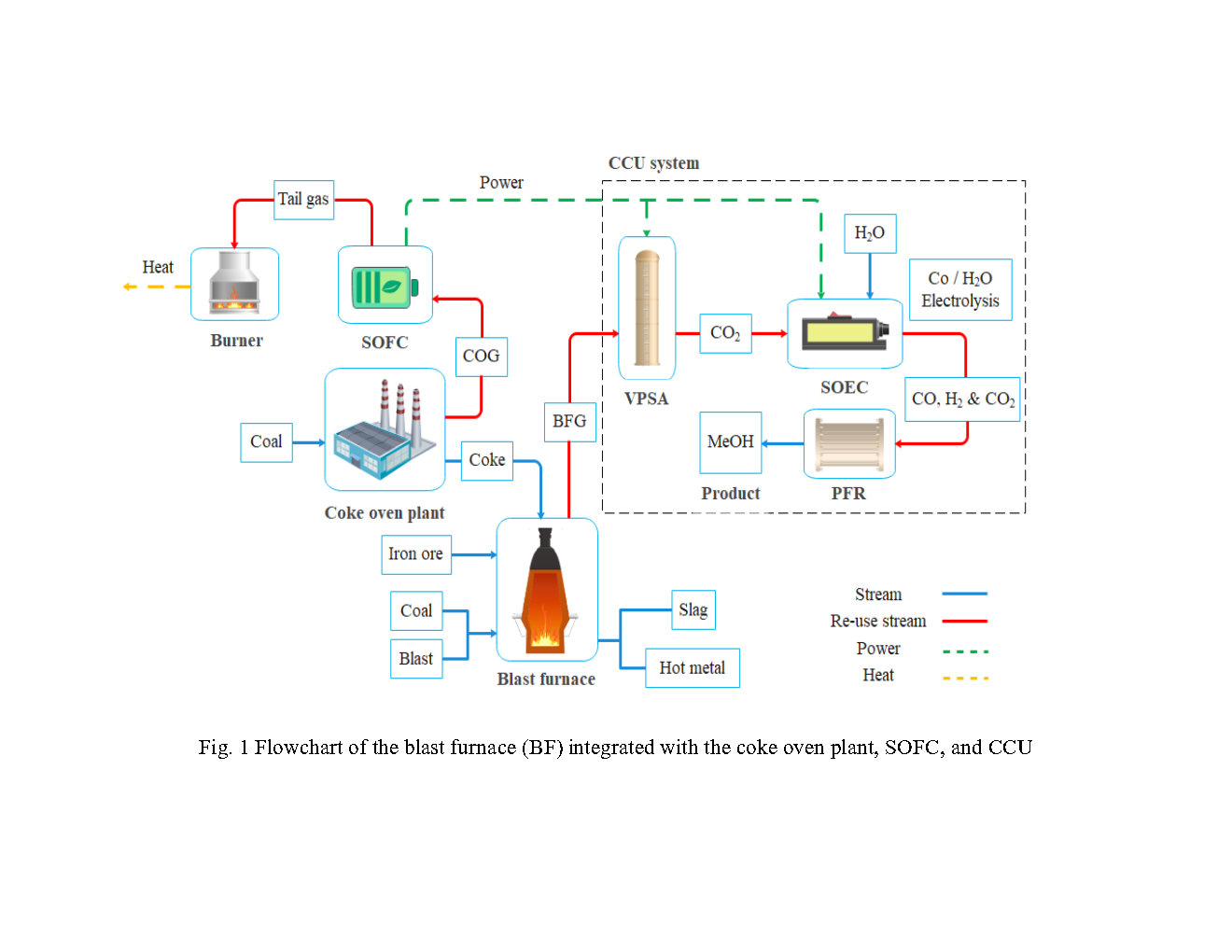

The blast furnace (BF) is not only a complicated metallurgical process, but it induces a large amount of CO2 emissions due to the coke and coal as sources of reducing agents for iron ore reduction. A new carbon capture and utilization (CCU) approach is connected to the top gas of BF system, which aims to convert the captured CO2 into the methanol fuel through the co-electrolysis of steam and CO2 in a solid oxide electrolyzer cell (SOEC). The external power supply is based on an integration of the coke oven plant and the solid oxide fuel cell (SOFC). The proposed integrated ironmaking process is depicted in Fig. 1. The thermodynamics of chemical metallurgy for the BF model is extracted from FactSage® and the BF model validation is achieved by using Aspen Plus®. The heat exchanger network is involved to improve the heat recovery of the integration of BF and CCU. It is validated that the total CO2 emissions of the BF with CCU is lower than the BF without CCU by 33% and the energy conversion efficiency of the CCU is close to 30.9%.