2024 AIChE Annual Meeting

(430g) Characterization of Biobased Films Developed from Ecuadorian Agro-Industrial Waste: In the Framework of a Circular Bioeconomy and Circular Engineering

Authors

The objective of this study was to explore the potential of the direct use of residual biomass, from Ecuadorian agroindustries, for the production of biobased films. Bioresidues included avocado (Persea americana, Fuerte variety) seeds, green plantain (Musa paradisiaca) peels, mango (Mangifera indica L.) cotyledons, cocoa (Theobroma cacao L.) pod husks, and vegetable ivory (Phytelephas aequatorialis) meal residues. Given the chemical composition of the bioresidues; avocado seed, mango cotyledon and green plantain peel were considered as sources of starch. On the other hand, cocoa pod husk was considered a source of cellulose and vegetable ivory meal residue as a source of mannan. Before being used, the biomass samples were subjected to a pretreatment that consisted of a Soxhlet extraction with 70% ethanol, subsequently dried and ground until obtaining particles of size 63 µM approximately.

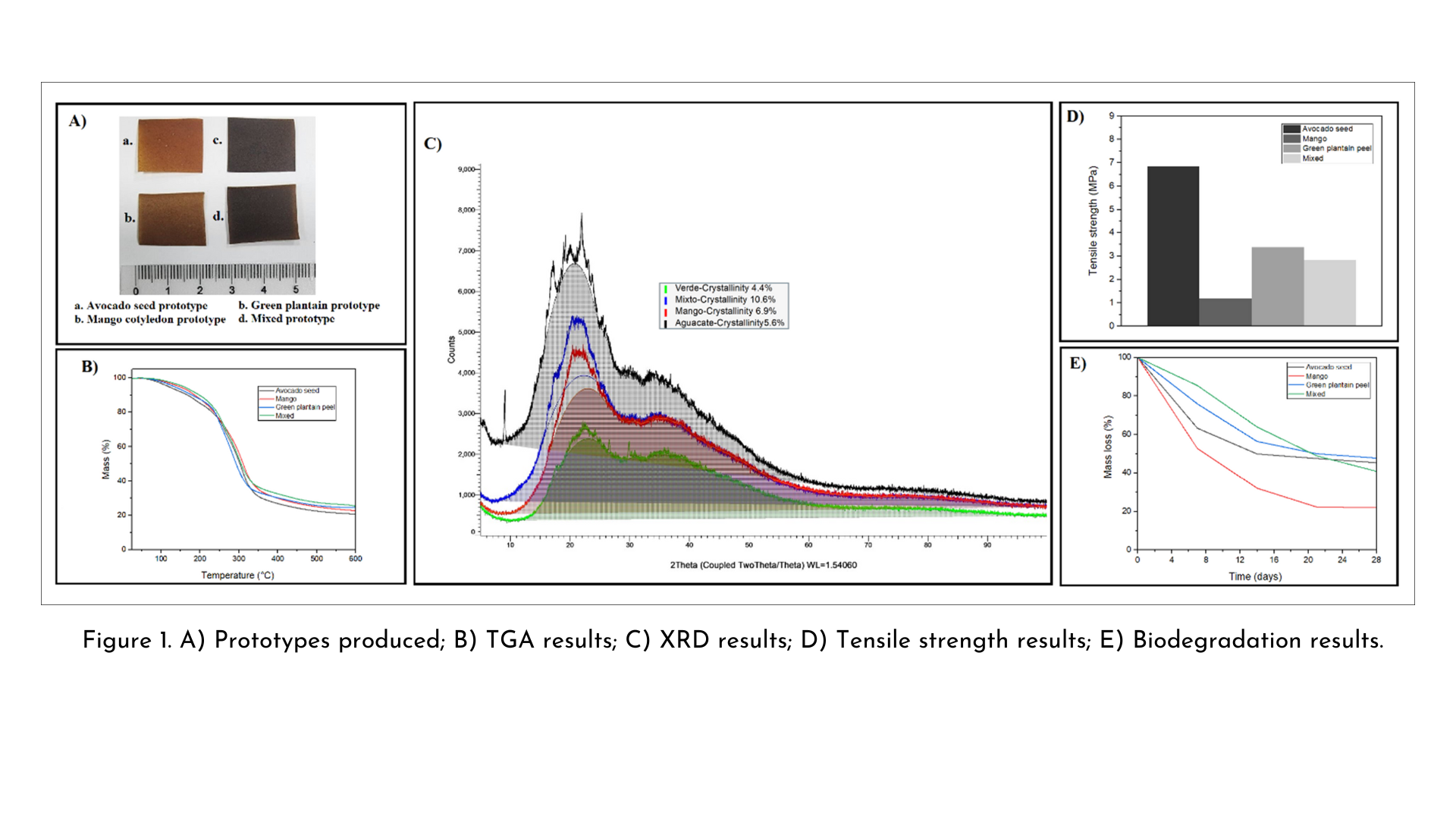

Four prototypes of biobased films were produced, which were analyzed for their thermal stability, crystallinity, tensile strength, and biodegradation rate. Each biobased film consisted of 90% starch biomass, 5% cellulose biomass and 5% mannan biomass. For the mixed prototype, the starch sources were divided into three equal parts (30% avocado seed; 30% mango cotyledon; 30% green plantain peel). The thermal stability was determined through a Thermal Gravimetric Analysis (TGA) [9]; the crystallinity by X-RAY Diffraction (XRD) [9]; the tensile strength through a universal testing machine; biodegradation was determined by the difference in mass of the films in a controlled environment with soil [10].

Films of 0.36-0.41mm thickness, flexible in texture, and opaque were produced (Figure 1A). From the TGA results, a very similar behavior was observed among all the generated curves, with 100-200°C being the range in which these prototypes have adequate thermal stability to be used (Figure 1B). Regarding crystallinity, an absorption peak between 2θ = 15-28° was observed for all prototypes (Figure 1C), which indicates the presence of starch, of which an amorphous and semicrystalline structure has been reported [11]. The avocado seed film presented greater crystallinity in relation to the others. This difference could be related to the amylose content of the avocado seed [12]. Regarding tensile strength, variable measurements are observed between the prototypes (Figure 1D), with the avocado film being the one with the greatest resistance (Figure 1C). Finally, from the biodegradation test it was determined that after 28 days, the mass loss was above 50% for all cases (avocado seed prototype=54.71%; mango cotyledon prototype=77.98%; green plantain peel prototype=52.3%; mixed prototype=59.16%), being the mango cotyledon film the one with the highest rate (Figure 1E). Both the physical and the chemical composition of biopolymer-based materials affect their biodegradability, as well as factors such as humidity, pH, oxygen content, nutrient availability, and others [13].

Through this study it is concluded that it is possible to use residual biomass to produce biobased films without prior isolation of its polymeric components. However, challenges arise to improve the mechanical properties of these materials, to be suitable for their intended application. From the prototypes obtained, the avocado seed film turned out to be the most resistant and with the best physical properties, representing a starting point for future studies and applications. Finally, there is much to explore and take advantage of agro-industrial waste in Ecuador, which opens the way to new opportunities to create products for everyday consumption, in a more sustainable way and within the framework of a circular bioeconomy and circular engineering.

References

[1] Center for International Forestry Research (CIFOR), “The Circular Bioeconomy Knowledge Guide,” 2021. Accessed: Mar. 27, 2024. [Online]. Available: https://www.cifor.org/wp-content/uploads/2021/03/Flyer%20-%20Knowledge%…

[2] F. C. Lopes and R. Ligabue-Braun, “Agro-Industrial Residues: Eco-Friendly and Inexpensive Substrates for Microbial Pigments Production,” Front Sustain Food Syst, vol. 5, Mar. 2021, doi: 10.3389/fsufs.2021.589414.

[3] P. R. Yaashikaa, P. Senthil Kumar, and S. Varjani, “Valorization of agro-industrial wastes for biorefinery process and circular bioeconomy: A critical review,” Bioresour Technol, vol. 343, p. 126126, Jan. 2022, doi: 10.1016/j.biortech.2021.126126.

[4] F. Torres, F. Guerrero, C. Varas, and T. Solis, “View of Circular economy vision for local development focused on waste derived from two agricultural crops in Ecuador,” Journal of Business and Entrepreneurial Studies, vol. 6, 2022.

[5] S. Aguiar, M. Enríquez Estrella, and H. Uvidia Cabadiana, “Residuos agroindustriales: su impacto, manejo y aprovechamiento,” AXIOMA, vol. 1, no. 27, pp. 5–11, Dec. 2022, doi: 10.26621/ra.v1i27.803.

[6] L. O. Palma Gallardo and J. Alba Flores, “Do all Plastics Damage the Environment?,” Front Young Minds, vol. 10, Sep. 2022, doi: 10.3389/frym.2022.722532.

[7] P. Li, X. Wang, M. Su, X. Zou, L. Duan, and H. Zhang, “Characteristics of Plastic Pollution in the Environment: A Review,” Bull Environ Contam Toxicol, vol. 107, no. 4, pp. 577–584, Oct. 2021, doi: 10.1007/s00128-020-02820-1.

[8] J. X. Chan, J. F. Wong, A. Hassan, and Z. Zakaria, “Bioplastics from agricultural waste,” in Biopolymers and Biocomposites from Agro-Waste for Packaging Applications, Elsevier, 2021, pp. 141–169. doi: 10.1016/B978-0-12-819953-4.00005-7.

[9] L. F. Zambrano-Mite et al., “Optimization of microfibrillated cellulose isolation from cocoa pod husk via mild oxalic acid hydrolysis: A response surface methodology approach,” Heliyon, vol. 9, no. 6, p. e17258, Jun. 2023, doi: 10.1016/j.heliyon.2023.e17258.

[10] Md. R. Amin, M. A. Chowdhury, and Md. A. Kowser, “Characterization and performance analysis of composite bioplastics synthesized using titanium dioxide nanoparticles with corn starch,” Heliyon, vol. 5, no. 8, p. e02009, Aug. 2019, doi: 10.1016/j.heliyon.2019.e02009.

[11] O. S. Jangong, P. L. Gareso, I. Mutmainna, and D. Tahir, “Fabrication and characterization starch/chitosan reinforced polypropylene as biodegradable,” J Phys Conf Ser, vol. 1341, no. 8, p. 082022, Oct. 2019, doi: 10.1088/1742-6596/1341/8/082022.

[12] E. Indarti, Nurlaila, M. Muzaifa, S. Noviasari, Z. F. Rozali, and E. M. Yusup, “Characteristics of avocado (Persea americana) and kluwih (Artocarpus camansi) seeds starch with different extraction methods,” IOP Conf Ser Earth Environ Sci, vol. 951, no. 1, p. 012095, Jan. 2022, doi: 10.1088/1755-1315/951/1/012095.

[13] A. Folino, A. Karageorgiou, P. S. Calabrò, and D. Komilis, “Biodegradation of wasted bioplastics in natural and industrial environments: A review,” Sustainability (Switzerland), vol. 12, no. 15. MDPI, Aug. 01, 2020. doi: 10.3390/su12156030.