2024 AIChE Annual Meeting

(385aa) Upcycling Linear Low-Density Polyethylene Waste into Graphene for High Mass Loading Supercapacitors

Authors

Yuan Gao - Presenter, National Energy Technology Laboratory

Ngoc Tien Huynh, National Energy Technology Laboratory

Ki-Joong Kim, National Energy Technology Laboratory

Congjun Wang, AECOM

Christopher S. Matranga, National Energy Technology Laboratory

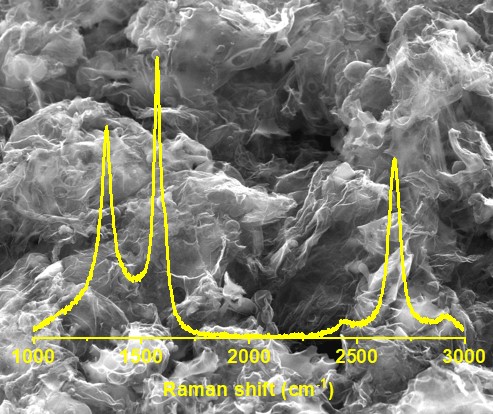

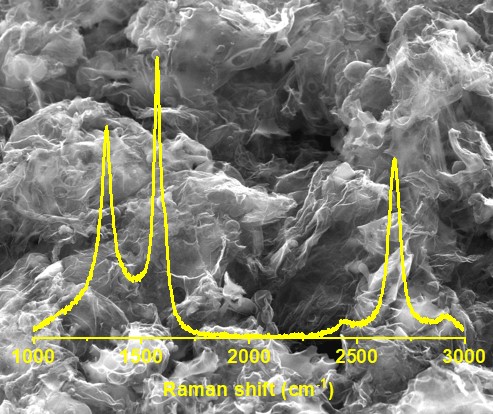

Plastic pollution is triggering a global environmental crisis, prompting research efforts in recycling and upcycling to address this challenge. Upcycling plastic into value-added carbons, such as graphene and porous carbon, offers attractive options to manage waste streams by converting the plastic into carbon electrode materials for energy storage devices. Polyethylene is notoriously difficult to upcycle because it decomposes into light gases at approximately 350-400 °C which prevents processing it at higher temperatures to convert it into electrode materials. We address this challenge by using an air-based, thermo-oxidative process along with a solid surface area enhancer, which heats linear low-density polyethylene (LLDPE) just below the decomposition point to initiate oxidation and cross-linking of LLDPE alkyl chains. These molecular transformations allow LLDPE to be processed into char at approximately 800 °C or graphenized at 950 °C without decomposing. The LLDPE-derived graphene (LLDPE-G) has a Brunauer–Emmett–Teller (BET) specific surface area up to 1,800 m2/g and Raman ID/IG ratio of 0.85. When used as electrode material for a symmetric supercapacitor with the 1 M H2SO4 electrolyte, LLDPE-G possesses an outstanding specific capacitance up to 175 F/g at mass loading of 20 mg/cm2, twice the commercial requirement, yielding an excellent areal capacitance of 3.5 F/cm2. Moreover, LLDPE-G exhibits exceptional cycling stability with capacitance retention of 95.8% after 100,000 cycles at high current density of 4.0 A/g. Last, but not least, KCl is recycled and reused over three cycles with material quality and electrocapacitive performance of LLDPE-G retained and verified after each cycle. Our approach creates new opportunities for upcycling not only waste LLDPE but also other PEs to high value graphene materials for electrochemical energy storage device applications.