The composition of syngas derived from gasification of carbonaceous fuels is not suitable for methanol production, and the overall methanol production process is comprised of multiple sub-processes. The resulting high costs can be reduced by intensification of individual units. Conventionally, process intensification is obtained by optimization of one sub-unit (e.g., reactor) at a time, even though typical process units interact by transfer of heat and mass. The optimization of catalytic fixed-bed reactors and the interaction between the individual units is addressed in the present work with an objective of intensifying the overall methanol production process.

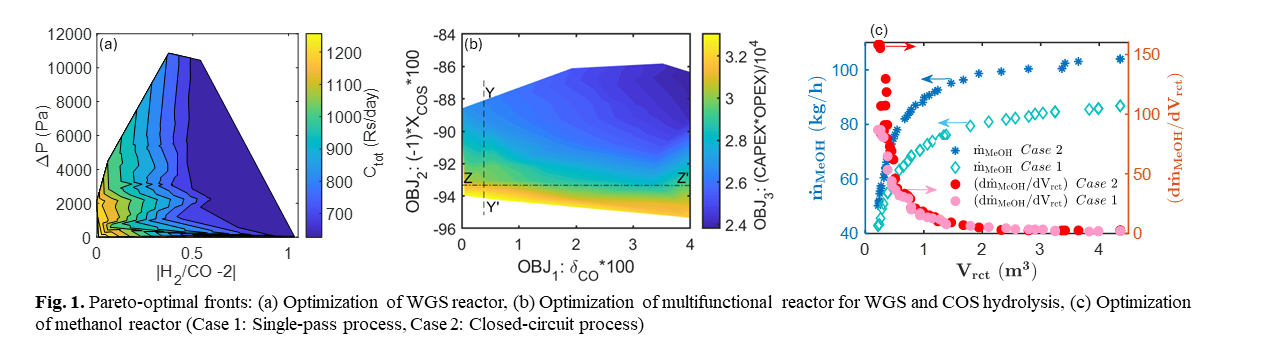

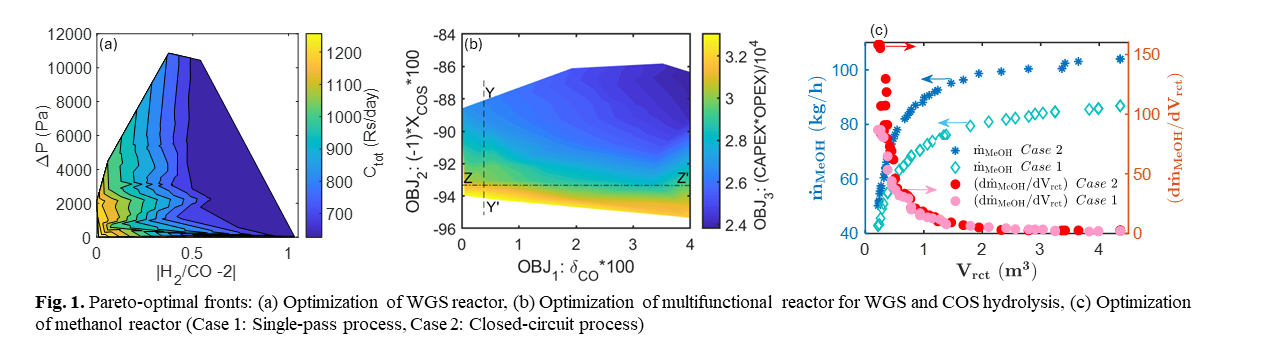

Dynamic 1D+1D models for three systems, viz., water-gas shift (WGS), COS hydrolysis, and methanol production are coupled with multi-objective NSGA-II algorithm, and different systems are optimized. First, optimum design variables are identified for attaining the required H2/CO ratio from a WGS reactor while minimizing the pressure drop and operating costs. In another study, the possibility of carrying both water-gas shift and COS hydrolysis reactions in a single multi-functional reactor is assessed. The reactor and the associated heat exchanger network are optimized simultaneously, and a heat-integrated multi-functional reactor is thus proposed. It is shown that the required CO and COS conversions can be achieved in a single reactor, wherein feed temperature and steam flow rates are major factors determining the COS conversion. In another study, single-pass and closed-circuit methanol production units are optimized while considering the effect of upstream units for syngas cleanup and conditioning. In contrast to conventional knowledge, it is shown that the optimal concentration of CO2 in the reactor feed depends on the design production capacity. While the results obtained pave the way for efficient methanol production, the methodological framework also finds application in optimization of other industrial processes with a network of sub-processes which require multiple heating and cooling applications.