Microkinetic models are important tools in both business and policymaking for evaluating industrial processes' efficiency and chemicals’ environmental impact. Manual construction of these models is difficult, error-prone, and time-consuming, motivating the shift towards automated development methods. This study introduces SIMBA (SImplest Mechanism Builder Algorithm), a novel approach aimed at simplifying the generation of microkinetic models by accurately reflecting kinetic data without prior knowledge of the system.

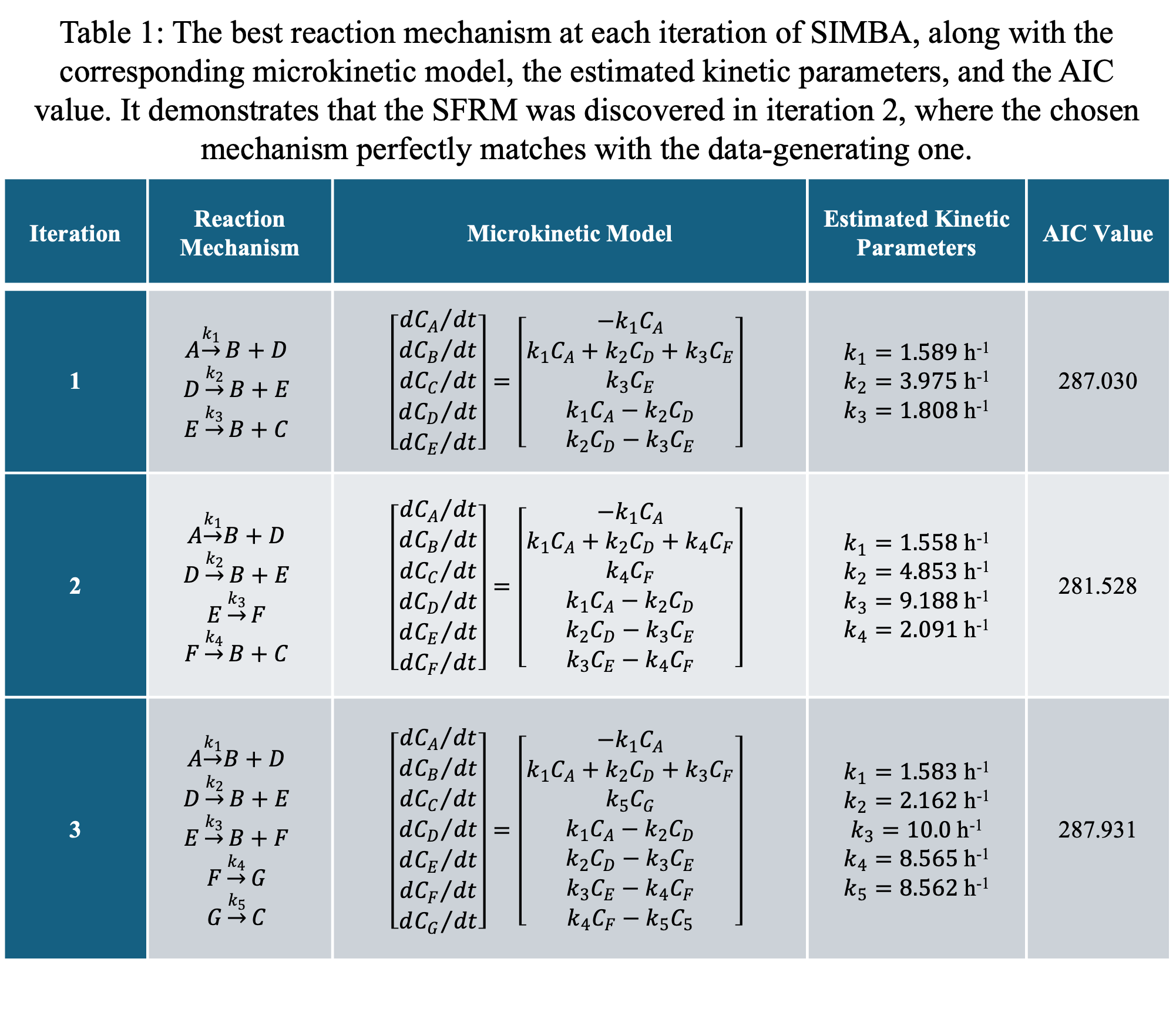

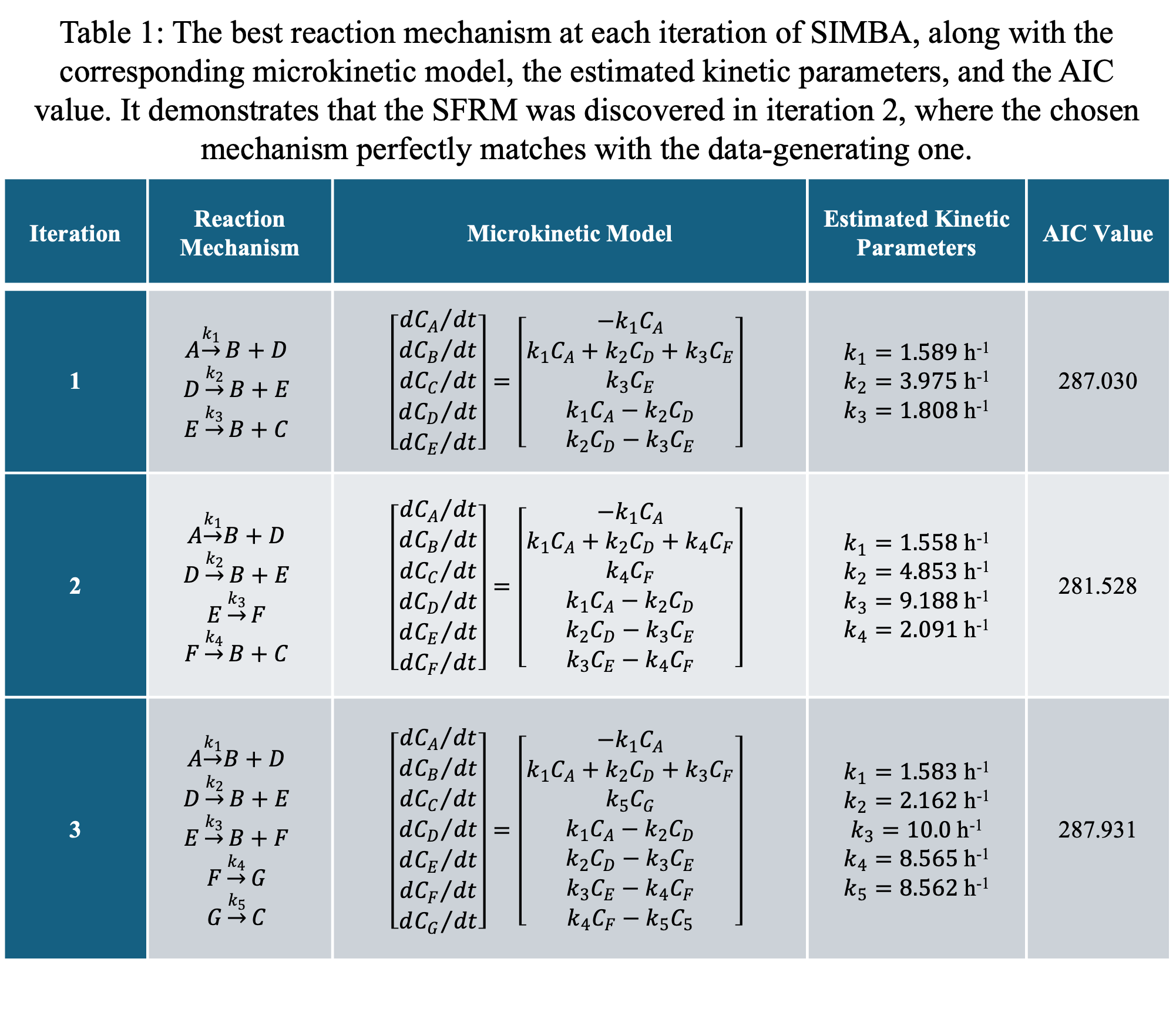

SIMBA operates through four key phases: generating plausible reaction mechanisms, starting from the most basic mechanism and adding complexity iteratively; transforming mechanisms into microkinetic models represented by a system of ordinary differential equations; optimizing these models to fit observed kinetic data; and comparing models to select the optimal one based on the Akaike Information Criterion (AIC). This methodology allows for the efficient and accurate development of microkinetic models, addressing the challenges posed by traditional methods and other automated approaches that may yield overly complex mechanisms or depend heavily on knowledge of reaction classes.

A case study on the dehydration of fructose to 5-hydroxymethylfurfural (HMF), catalyzed by [BmimHSO3][HSO4], exemplifies SIMBA's effectiveness. Utilizing a proposed mechanism with three dehydration steps and corresponding intermediates, SIMBA recovered the data-generating mechanism within just three iterations. This outcome not only demonstrates SIMBA’s capability to distill complex kinetic behavior into a simple yet accurate representation but also highlights its potential as a kinetic discovery tool.

While SIMBA effectively predicts intermediates and optimizes kinetic parameters, it does not chemically identify intermediates, necessitating expert input for complex systems. Despite this limitation, SIMBA enhances mechanistic exploration, offering a robust initial mechanism ‘guess’ that aids the rapid development and optimization of chemical processes. Future enhancements will focus on incorporating uncertainty quantification and integrating chemical knowledge to improve SIMBA's capabilities in identifying and refining microkinetic models, making it a better tool for chemists and reaction engineers.