The application of core-shell catalysts in catalysis has gained significant traction, particularly in processes generating energy such as syngas and liquid fuels. This study focuses on the fabrication of core-shell catalysts comprising a Ni-Al2O3 core coated with a silica (SiO2) film for methane dry reforming reactions. The unique structure aims to enhance catalytic activity and stability. The spherical core-shell design provides ample surface area for catalytic reactions, while the SiO2 shell prevents sintering of active metal particles. The preparation involves a multi-step process: initial synthesis of the Ni-Al2O3 core via impregnation, followed by SiO2 shell deposition using a rotary evaporator. The porous nature of SiO2 allows gas diffusion, which is crucial for the reaction.

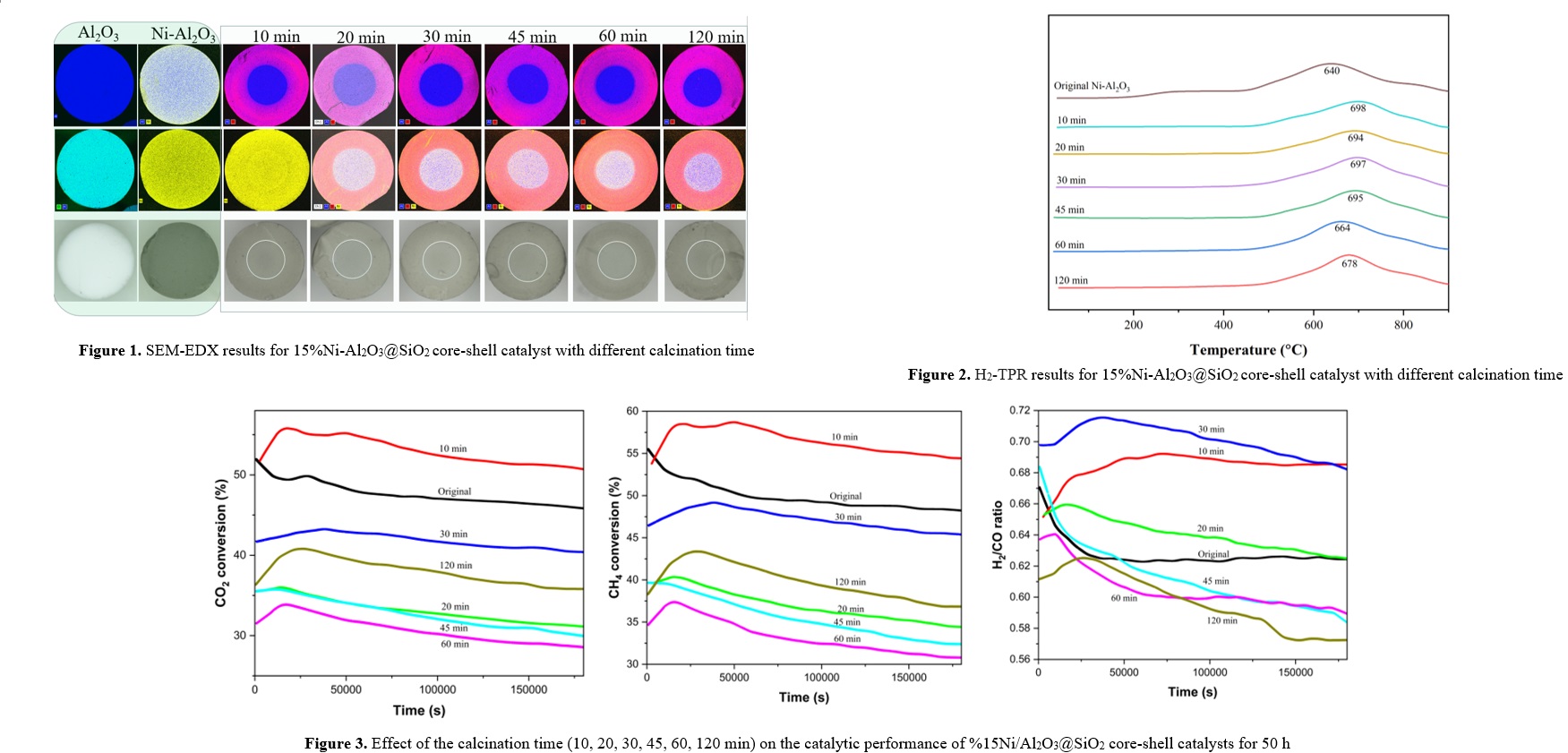

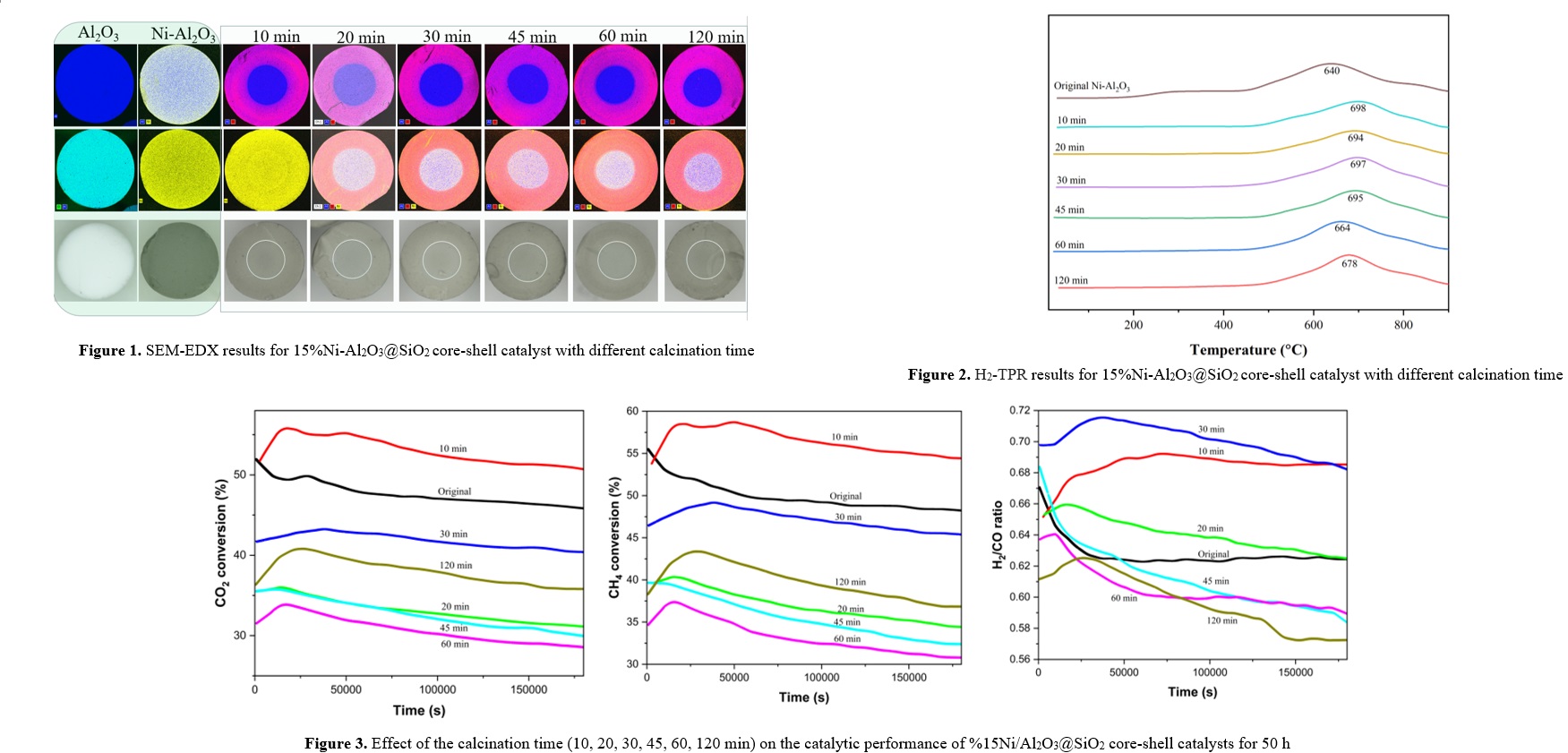

Various parameters like calcination time, temperature, and SiO2 precursor amount affecting shell thickness and, consequently, catalytic performance are investigated. SEM-EDX analysis (Figure 1) reveals a successful coating of Ni-Al2O3 with SiO2, with shell thickness decreasing with longer calcination. H2-TPR analysis (Figure 2) indicates higher reduction temperatures, suggesting prolonged H2 diffusion through SiO2, protecting Ni particles.

The effect of calcination time on the catalyst's performance is examined under specific reaction conditions (Figure 3). Results show the 10-minute calcined sample exhibits the highest conversion and stability, attributed to SiO2 preventing Ni particle sintering. Longer calcination times lead to reduced conversion and stability. Unlike the original Ni-Al2O3 catalyst, core-shell samples initially increase in conversion before stabilizing. According to the literature, the reason for increasing the stability of core-shell samples is that the presence of SiO2 shell can prevent the sintering of Ni particles on the surface of the catalysts.

In conclusion, this research presents a novel 3D catalyst approach with a Ni-Al2O3 core and SiO2 shell for methane dry reforming. These catalysts demonstrate high activity, selectivity, and stability, offering promise for industrial synthesis gas production applications.