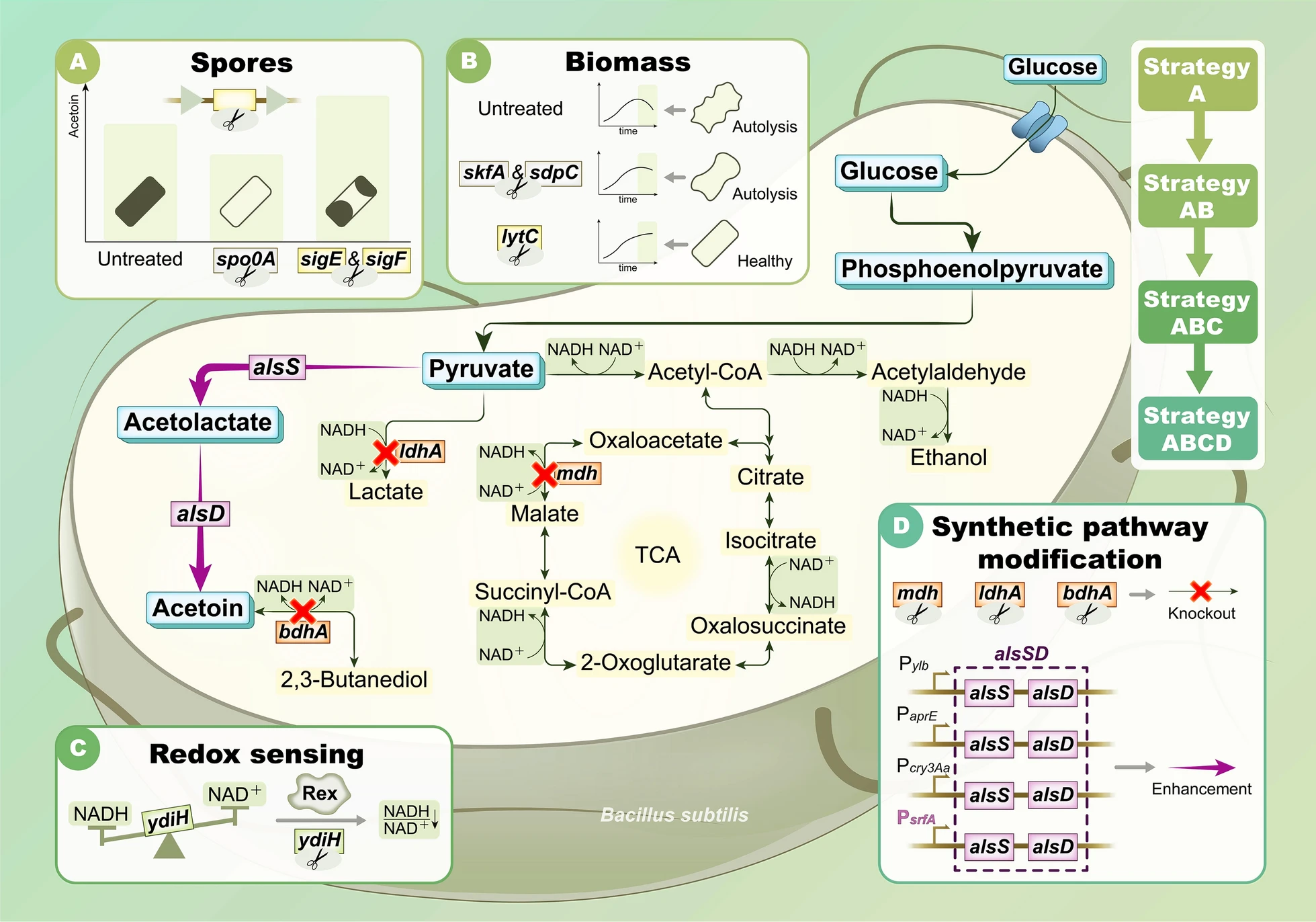

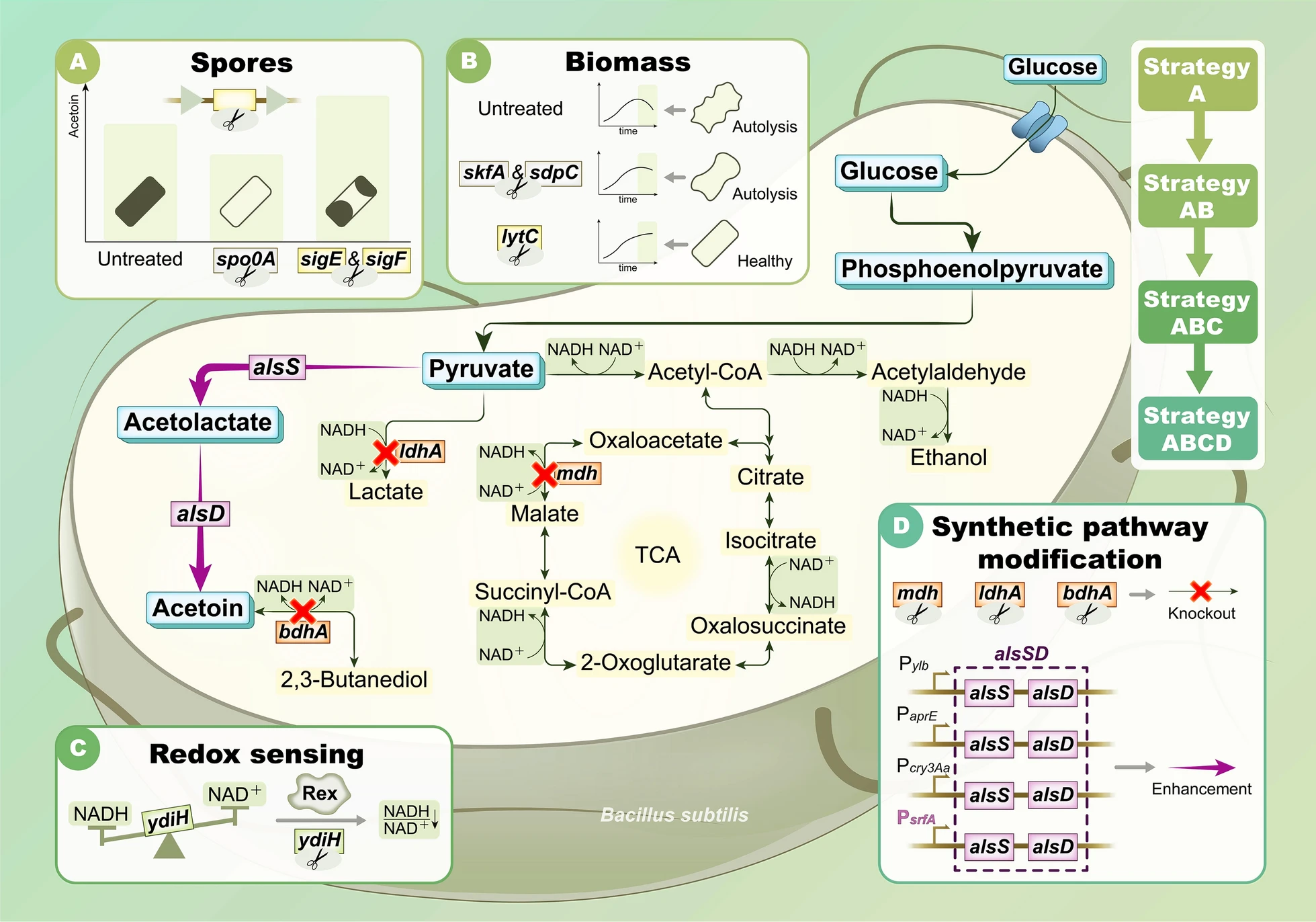

Acetoin (AC) is an important platform chemical widely used in the food, pharmaceutical and chemical industries. With the increasing concerns about non-renewable resources and environmental issues, the production of acetoin through microbial fermentation using low-cost biomass raw materials is undoubtedly a promising strategy. To enhance the continuous production capacity of

Bacillus subtilis and reduce unnecessary energy and material consumption, by knocking out the genes of cells involved in spore formation and autolysis, the fermentation density of cells during the production process was enhanced, and the yield of acetoin and cell biomass was improved by 22% and 18% respectively. Studies have found that

B. subtilis senses changes in the NADH/NAD

+ ratio through Rex protein to regulate intracellular redox homeostasis and binds to the promoter regions of many genes to inhibit gene expression. This process can be inhibited by NADH and deinhibited by excess NAD

+. Knocking out the regulatory gene

ydiH of the Rex protein resulted in a significantly lower NADH/NAD

+ ratio than the starting strain. This reduced ratio favors optimized intracellular carbon flux distribution and promotes the production of acetoin, which directly leads to a reduction in relevant by-products of the NADH-dependent pathway. Finally, different population cell density-induced promoters were screened to enhance the expression of key enzymes in the main pathway of acetoin synthesis. By modifying

B. subtilis chassis cells and modular metabolic engineering, the modified recombinant strain was fermented in a 5L bioreactor using sugarcane bagasse lignocellulosic hydrolyzate. The final titer of acetoin was 64.3 g/L. With a theoretical yield of 89.5%, this study provides a cost-effective method for the production of acetoin.