2023 AIChE Annual Meeting

(617g) Modelling and Optimization of Layered Bed Adsorbers for Post-Combustion CO2 Capture

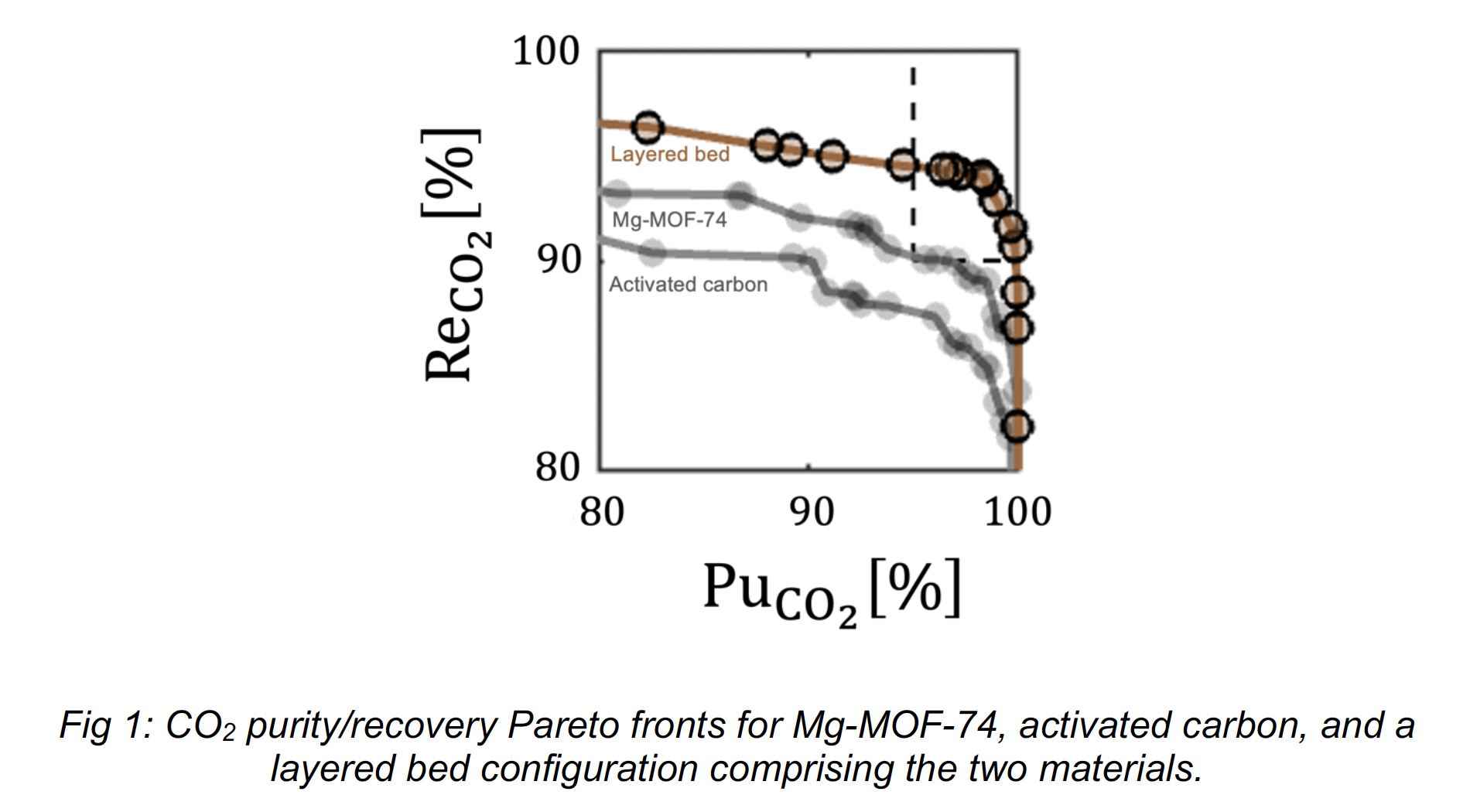

In this work, we investigate packed bed adsorbers utilizing two adsorbent materials arranged into successive layers. We have assessed binary combinations of four widely studied adsorbent materials; zeolite 13X, activated carbon, Mg-MOF-74 and UTSA-16. We have predicted the performance of each bed configuration in a typical four-step vacuum swing adsorption process using a detailed process model comprising material and energy balances which have been solved numerically using a finite volume scheme in MATLAB [4-6]. The modelling approach implicitly accounts for the presence of layers in the packed bed by embedding spatial heterogeneities in the bed and adsorption properties of the system within the spatial discretisation scheme. We use the process model to predict the purity and recovery of CO2 extracted from the flue gas, and the energy usage of the process per tonne of CO2 captured. We have coupled the process model to a process design framework to optimize the performance of each layered bed adsorber configuration. First, we consider unconstrained optimization wherein we maximize the purity and recovery of extracted CO2 in a multi-objective optimization problem by manipulating the process operating conditions and the loading of each material in the bed. Second, we consider minimization of the energy penalty of the separation, subject to regulatory constraints on the CO2 purity (>95%) and recovery (>90%). Each optimization problem has been solved using a state-of-the-art Bayesian optimization algorithm, to allow for efficient and effective solution of the design [5, 7].

We have found that several of the considered bed configurations present a separation enhancement in terms of the purity/recovery trade-off. As shown in Fig.1, a bed configuration with an initial layer of Mg-MOF-74 at the feed end of the column and a secondary layer of activated carbon at the product end of the column can outperform either of the corresponding single-adsorbent beds. We have used the model-based design environment to probe the underlying bed dynamics which allow for this separation enhancement and propose a mechanism by which the observed separation enhancement is manifested. For this bed configuration, we have further carried out constrained energy penalty minimization subject to the regulatory requirements on CO2 purity/recovery. We find that the layered bed process can achieve a 19% lower energy penalty than either of the corresponding single-adsorbent beds.

We therefore contend that layered adsorption beds are an interesting approach for post-combustion CO2 capture which deserve further research efforts. Particularly, it will be important to consider efficient methodologies to handle material screening in such systems owing to the large material selection space encountered for the design of processes with multiple adsorbents.

References:

[1]: Chao et al. (2021): âPost-combustion carbon captureâ. Renewable and Sustainable Energy reviews (138).

[2]: Farmahini et al (2021): âPerformance-based screening of porous materials for carbon captureâ. Chemical Reviews (121).

[3]: Divekar et al (2020): âImproved CO2 recovery from flue gas by layered bed vacuum swing adsorption (VSA)â. Separation and Purification Technology (234).

[4]: Ward & Pini (2022): âIntegrated uncertainty quantification and sensitivity analysis of single-component dynamic column breakthrough experimentsâ. Adsorption (28)

[5]: Ward & Pini (2022): âEfficient Bayesian optimization of industrial-scale pressure-vacuum swing adsorption processes for CO2 captureâ. Industrial & Engineering Chemistry Research (61).

[6]: Haghpanah et al. (2013): âMultiobjective optimization of a four-step adsorption process for postcombustion CO2 capture via finite volume simulationâ. Industrial & Engineering Chemistry Research (52).

[7]: Hao et al. (2021): âEfficient hybrid multiobjective optimization of pressure swing adsorptionâ. Chemical Engineering Journal (423).