Mixed matrix membranes have been pursued gas separations, such as post-combustion carbon capture, and a key challenge is to fabricate thin film composite (TFC) membranes containing a defect-free selective layer (< 1 µm). Herein, we successfully prepared TFC membranes using a gutter layer of polydopamine (PDA) modified polydimethylsiloxane (

dPDMS). The selective layer (as thin as 200 nm) comprises bottlebrush amorphous polyethylene oxide (aPEO) and metal-organic frameworks (UiO-66-NH

2). The PDA layer (<10 nm) acts as a bio-adhesive promoting the formation enables a thin and defect-free aPEO/MOFs layer via hydrogen bonding between amine in PDA and ethylene oxide. Cross-sectional SEM presents a smooth mixed matrix selective layer confirming the good compatibility between aPEO and UiO-66-NH

2. For example, adding 10 mass% of UiO-66-NH

2 increases CO

2 permeance from 1200 to 2800 GPU and CO

2/N

2 selectivity from 40 to 50, presumably because the amine groups in UIO-66-NH

2 improves the compatibility between the MOFs and aPEO and affinity towards CO

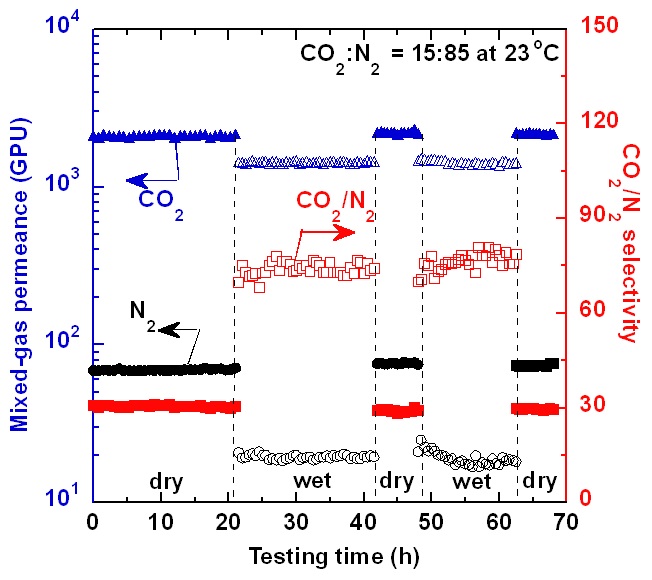

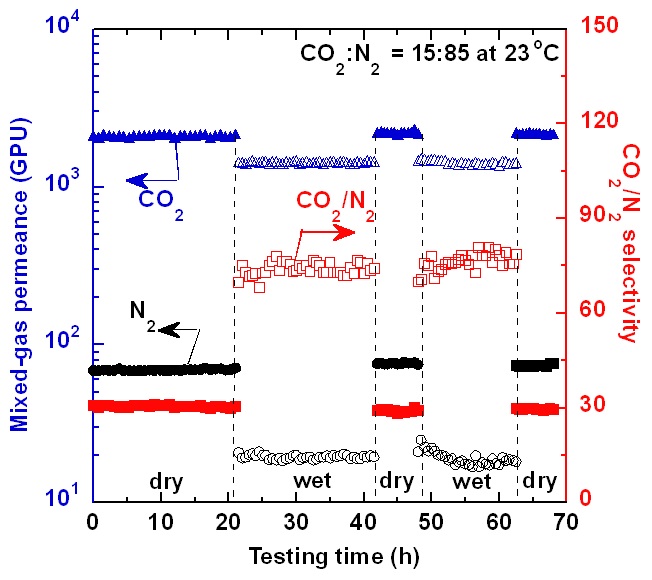

2. Conduction of mixed-gas and long-term stability test of aPEO/UIO-66-NH

2 TFC membranes show superior and stable separation performance under simulated flue gas conditions for 70 hours. Specifically, the membrane presents stable CO

2 permeance of 2200 GPU and CO

2/N

2 selectivity of 32 under mixed gas (CO

2:N

2=15:85) for 20 hours. When 1.2 mol% water vapor was introduced into the system, CO

2 permeance decreased to 1400 GPU, and CO

2/N

2 selectivity increased to 76, presumably because the water vapor swells the selective layer and amine groups facility transported the CO

2 under wet conditions. After two rounds of mixed gas tests (dry-wet-dry), the membrane exhibits stable and reversible separation properties. This showcases the potential benefits of fabricating high-performance TFC membranes using UIO-66-NH

2.