2023 AIChE Annual Meeting

(544h) Bridging the Gap between the Experimental and Computational Catalysis Communities: Recent Advances and Challenges

Authors

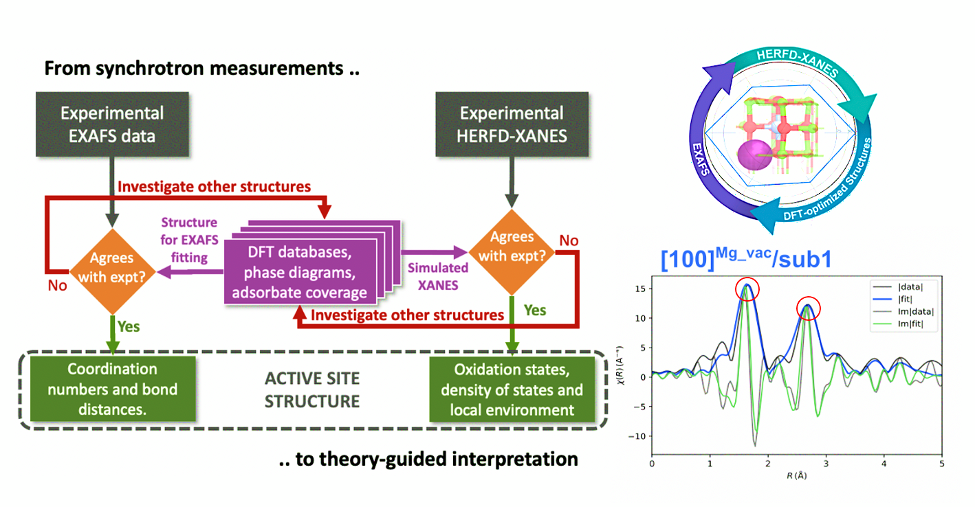

The overall goal of this talk is to discuss the role (and limitations) of QuantEXAFS within the catalysis science community. Using Pt/MgO calcined at 700 ºC and 400 ºC as a prototypical example, I will first discuss the limitations of conventional EXAFS analyses that led to the development of QuantEXAFS. Further, I will show how QuantEXAFS enabled the identification of different unique sites for the two calcination temperatures.5,6 I will show results to demonstrate that the complexity of zeolites can be handled and this method is robust in dealing with different support materials.7 I will present a summary of all the recent applications of this method on different catalytic materials with both internal and external collaborators. While QuantEXAFS is a useful tool, it has limitations and these will be discussed in the talk along with the best practices and common pitfalls. In the end, Iâll talk about unpublished results that show how we can start tackling site heterogeneityâ the fractions of different atomically dispersed sites present in a single catalytic sample.

With more and more emphasis on machine learning and FAIR data practices it becomes essential to explore tools like QuantEXAFS. Moreover, it is important to equip the catalysis community with powerful (combined) experimental-theory driven methods. Bridging the gap between experimental catalysis and computational catalysis communities requires participation from many communities, Iâll highlight the key outlooks and future directions for such advanced bridging approaches in the field of fundamental catalysis.8

References

(1) Li, Y.; Frenkel, A. I. Acc. Chem. Res. 2021, 54 (11), 2660â2669. https://doi.org/10.1021/acs.accounts.1c00180.

(2) Timoshenko, J.; Duan, Z.; Henkelman, G.; Crooks, R. M.; Frenkel, A. I. Annu. Rev. Anal. Chem. 2019, 12, 501â522. https://doi.org/10.1146/annurev-anchem-061318-114929.

(3) Xia, Y.; Campbell, C. T.; Roldan Cuenya, B.; Mavrikakis, M. Chem. Rev. 2021, 121 (2), 563â566. https://doi.org/10.1021/acs.chemrev.0c01269.

(4) Desai, S. P.; Ye, J.; Zheng, J.; Ferrandon, M. S.; Webber, T. E.; Platero-Prats, A. E.; Duan, J.; Garcia-Holley, P.; Camaioni, D. M.; Chapman, K. W.; Delferro, M.; Farha, O. K.; Fulton, J. L.; Gagliardi, L.; Lercher, J. A.; Penn, R. L.; Stein, A.; Lu, C. C. J. Am. Chem. Soc. 2018, 140 (45), 15309â15318. https://doi.org/10.1021/jacs.8b08550.

(5) Chen, Y.; Rana, R.; Sours, T.; Vila, F. D.; Cao, S.; Blum, T.; Hong, J.; Hoffman, A. S.; Fang, C. Y.; Huang, Z.; Shang, C.; Wang, C.; Zeng, J.; Chi, M.; Kronawitter, C. X.; Bare, S. R.; Gates, B. C.; Kulkarni, A. R. J. Am. Chem. Soc. 2021, 143 (48), 20144â20156. https://doi.org/10.1021/jacs.1c07116.

(6) Chen, Y.; Rana, R.; Huang, Z.; Vila, F. D.; Sours, T.; Perez-Aguilar, J. E.; Zhao, X.; Hong, J.; Ho, A. S.; Li, X.; Shang, C.; Blum, T.; Zeng, J.; Chi, M.; Salmeron, M.; Kronawitter, C. X.; Bare, S. R.; Kulkarni, A. R.; Gates, B. C. J. Phys. Chem. Lett. 2022. https://doi.org/10.1021/acs.jpclett.2c00667.

(7) Felvey, N.; Guo, J.; Rana, R.; Xu, L.; Bare, S. R.; Gates, B. C.; Katz, A.; Kulkarni, A. R.; Runnebaum, R. C.; Kronawitter, C. X. J. Am. Chem. Soc. 2022, 144 (30), 13874â13887. https://doi.org/10.1021/jacs.2c05386.

(8) Rana, R.; Vila, F. D.; Kulkarni, A. R.; Bare, S. R. ACS Catal. 2022, (12), 13813â13830. https://doi.org/10.1021/acscatal.2c03863.