2023 AIChE Annual Meeting

(462b) A Hybrid System for Capturing CO2 Directly from the Air

Authors

Today, the development of CO2 capture systems has focused mainly on single-stage separation technologies. For CO2 capture, aqueous amine scrubbing is the benchmark technology and is widely deployed in industry for natural-gas sweetening. For dilute sources containing a few per cent CO2, aqueous amine absorption processes work well and can achieve up to 90% CO2 capture and 98% purity. However, technological improvements are still required for large-scale CO2 capture using aqueous amines in terms of the energy requirement, solvent degradation, absorption capacity and equipment corrosion. In part due to these outstanding issues, alternative CO2 separation technologies have been developed. Adsorption-based technology for DAC has been developed commercially but is currently associated with high costs. Capturing CO2 in high purity from a ppm-level feed is indeed extremely demanding for a single technology. Generally, high energy consumption and poor economic performance are major challenges for all DAC technologies, seriously limiting economic feasibility. In this context, opportunities exist to develop hybrid processes for DAC, which might reduce the costs and increase operational flexibility. Hybrid processes are developed to overcome the challenges that standalone processes face; in this case to treat dilute, large volume, low pressure streams.

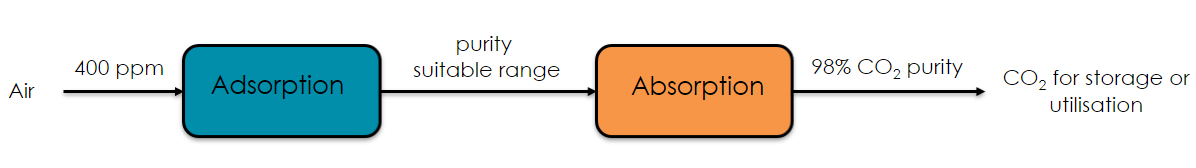

In this work, we assess the design of a hybrid process for capturing CO2 directly from ambient air. The hybrid process proposed in this study integrates adsorption and absorption as shown in Fig. 1. Absorption is a proven technology at the large scale, while adsorption processes benefit from high separation factors and the versatility given by the wide range of sorbent materials available. For the first stage, a temperature vacuum swing adsorption process is considered (TVSA), using commercial sorbents, such as activated carbon, zeolite 13X, Lewatit VP OC 1065 and CALF-20 while, for the second stage, an aqueous amine absorption process is developed. In the TVSA process studied, a six-step TVSA cycle was investigated, comprising the following steps: pressurization, adsorption, evacuation, pre-heating, desorption, and cooling. We evaluated the performance of different adsorbents in terms of the purity of CO2 produced and energy required to complete the purification, for a binary mixture of CO2/N2. With this cycle configuration, starting from 400 ppm CO2, the desorbed gas was enriched to between 0.5% and 12% CO2 with varying recoveries, depending on the adsorbent and the operating conditions. The energy consumption per ton of CO2 captured in the system is discussed for the different process configurations. We employ a genetic algorithm to optimize the operating conditions (operating pressure, intermediate heating temperature, desorption temperature, cycle step durations, feed rate of air stream) of the TVSA cycle for each examined sorbent.

For the second stage, we developed a rigorous rate-based absorption model in the Aspen Plus process simulator to simulate the purification of the CO2 to the desired 98% target. Aqueous amine solvents including monoethanolamine (MEA) and different amine blends were considered. A simplified meta model was developed to serve as a design tool for the optimization of the process. This took the form of empirical correlations abstracted from simulation data, using symbolic regression by the ALAMO algorithm. We have considered a range of CO2 feed gas compositions and CO2 loadings corresponding to different output streams of the TVSA cycle. The CO2 feed gas content, CO2 loading of lean and rich absorption liquid, liquid solvent circulation rate and the absorber size were found to be key determinants of the cost of capture. Technoeconomic optimization on this second stage was performed resulting in a purification cost of 79 $/tCO2 for the base case of 30 mass% MEA solvent. Moving forward, we will integrate the TVSA model of the first stage with the absorption model of the second stage to evaluate and optimize the overall performance of the hybrid system.

References:

1 M. Evans et al., 2022, Direct air capture: process technology, technoeconomic and socio-political challenges

2 M. Ozkan et al., 2022, Current status and pillars of direct air capture

3 Breyer et al., 2020 Carbon dioxide direct air capture for effective climate change mitigation based on renewable electricity: a new type of energy system sector coupling