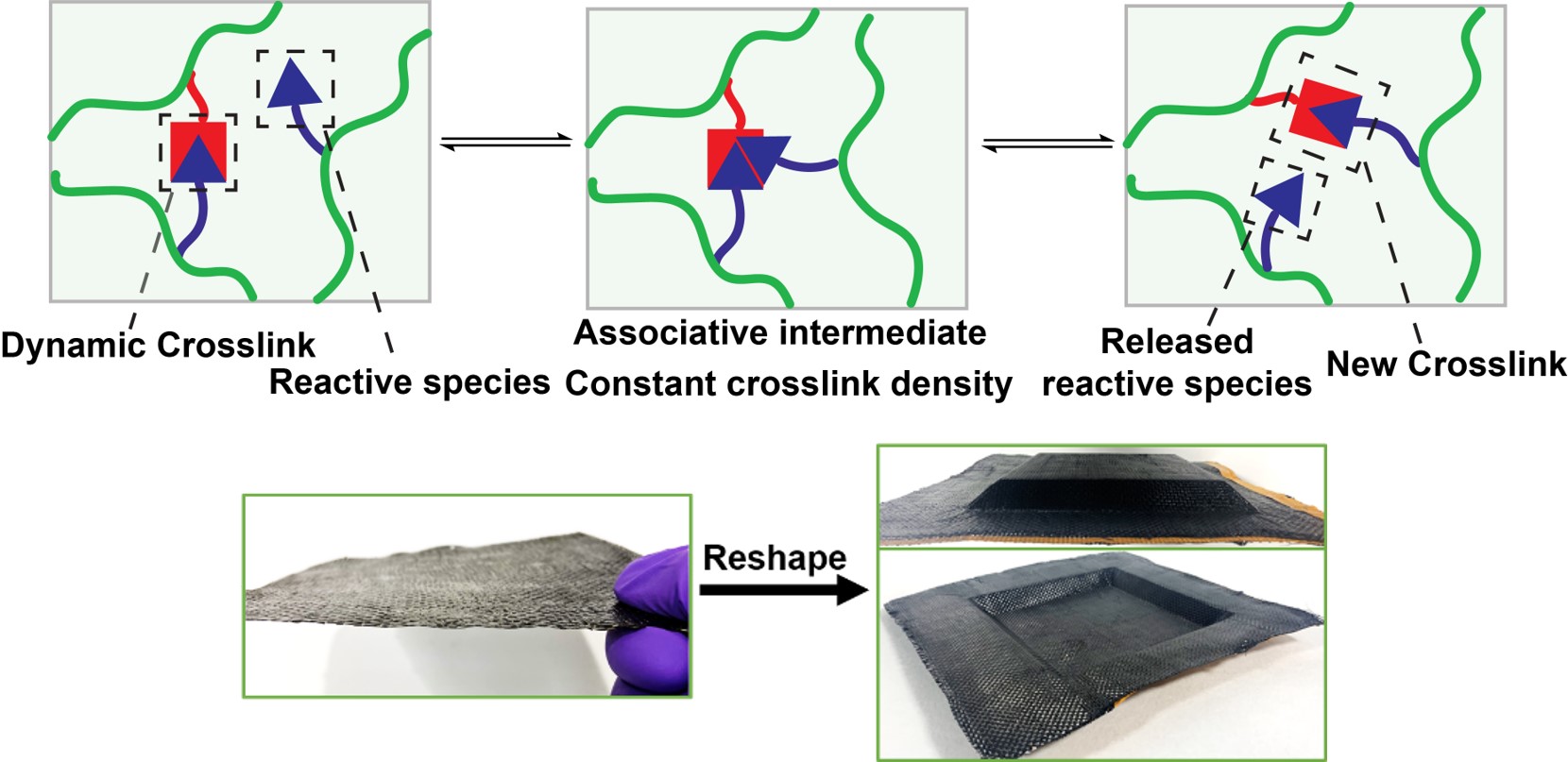

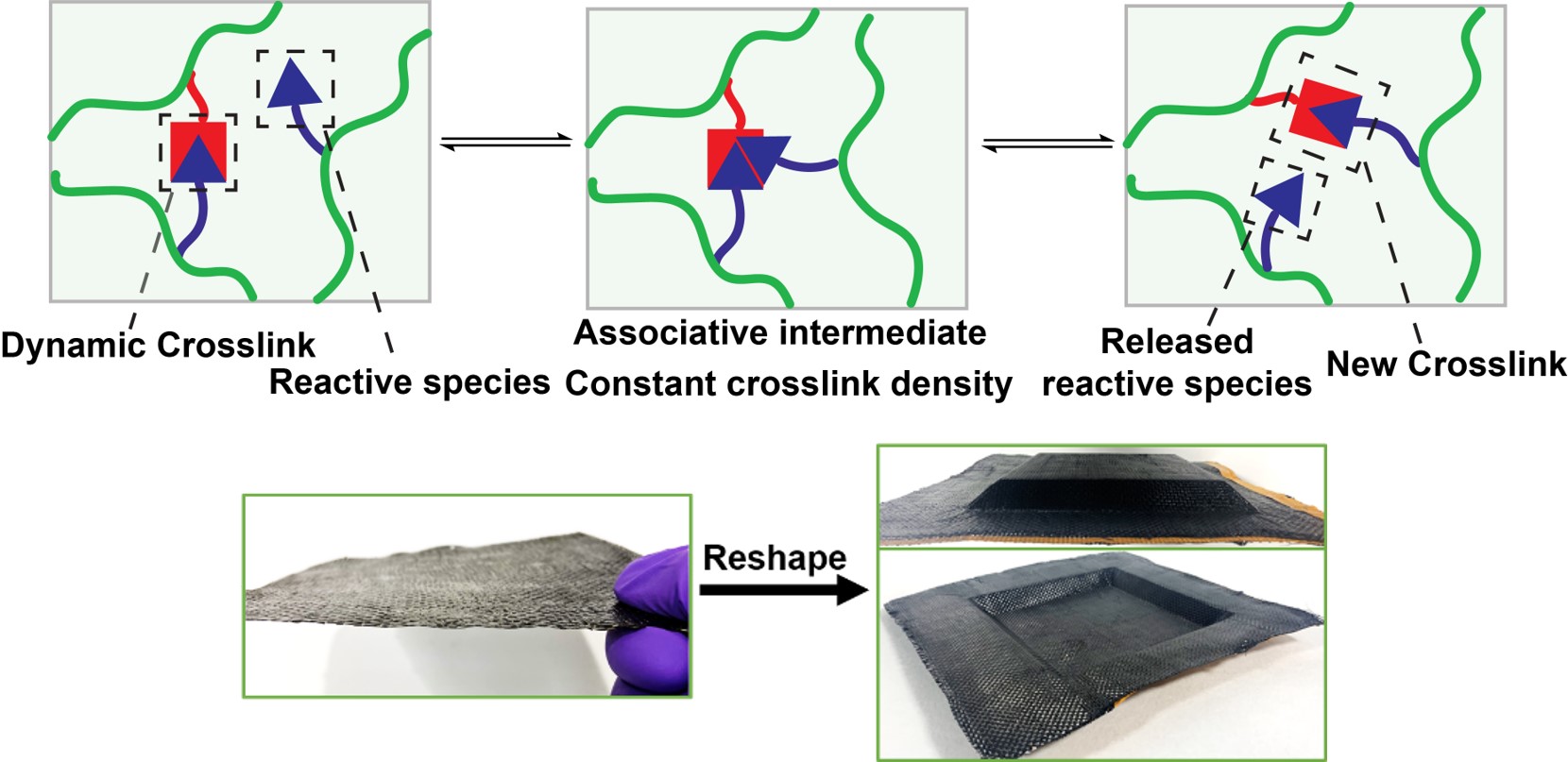

Manufacturing transformation towards a net-zero carbon society demands polymeric composites to be reprocessable in circularity in an energy-efficient and stable manner. Enabling recyclability and establishing circular manufacturing of currently non-recyclable polymers would significantly reduce global carbon intensity compared to traditional polymers. Carbon fiber-reinforced polymers (CFRPs) play a major role in enabling highly efficient energy usage in automobile and aerospace applications, because of their lightweight and robust mechanical properties. The rapid growth of CFRPs in various industries generates major environmental challenges in waste management. Most of the conventional CFRPs are very difficult to recycle and end up in the natural environment or a landfill because their resins are permanently crosslinked, preventing remolding, repairing, or recycling. In addition, the current epoxy-based CFRP manufacturing process is time-consuming, not cost-effective, and not ideal for efficient mass production. Moreover, carbon fiber (CF) production is energy-intensive (~198â595 MJ/kg) and causes large amounts of greenhouse gas emissions. Recycling CFs and CFRPs will significantly save energy consumption and reduce the manufacturing carbon footprint. In our study, novel vitrimer-based resins are designed and synthesized using a fast and robust dynamic exchange chemistry with tailored interfaces. The designed vitrimer chemistry enables the crosslinked network to be reprocessable and repairable, while providing strong interfacial adhesion between matrix and CFs. In one system, we report a simple design of dynamic polyurea/epoxy (DPE) vitrimers and their CFRPs with exchangeable disulfide crosslinks, that overcome intrinsic limitations of multi-cycle recyclability and rapid processability. Compared to conventional epoxy vitrimers, the DPE vitrimer exhibits 6 times faster bond rearrangement and ~40 °C lower reprocessing temperature, which enables full recovery of the mechanical strength throughout 6 reprocessing cycles, while the conventional vitrimer lost ~63% of strength. The CFRPs prepared with the DPE vitrimers exhibit facile multi-cycle processability and repairability by thermoformation. In another system, we have developed boronic-ester based vitrimers and their CFRPs that behave as an insoluble thermoset and flowable thermoplastic upon heating. The dynamic covalent bonding at CFRPs improved fiber-matrix interfacial adhesion, superior mechanical properties, repairability, and recyclability. These design principle can promote the development of highly sustainable, efficient and low-carbon manufacturing of next-generation CFRPs, that can be widely adopted in lightweight materials for applications in various clean energy technologies. This presentation will summarize our effort in the design, synthesis, and processing of vitrimer-based CFRPs for circular economy.