2023 AIChE Annual Meeting

(429h) Customization of an Entropy Generation Minimization Block in Aveva Process Simulation

Authors

The present study describes the customization of a thermodynamic evaluation block in AVEVA Process Simulation (APS) based on the application of the concept of entropy generation minimization, creating the EGM block. APS is a widely-used software for process simulation, optimization, and process design. Specifically, the approach for constructing the EGM block involves the use of the Model Writing mode in APS for the reduction of the system's entropy generation rate in order to define optimal operating conditions, demonstrating the effectiveness of EGM in improving the efficiency and performance of chemical processes. The production of propylene glycol by the hydration of propylene oxide in a Continuous Stirred-Tank Reactor (CSTR) is used as the case study to demonstrate the proposed approach.

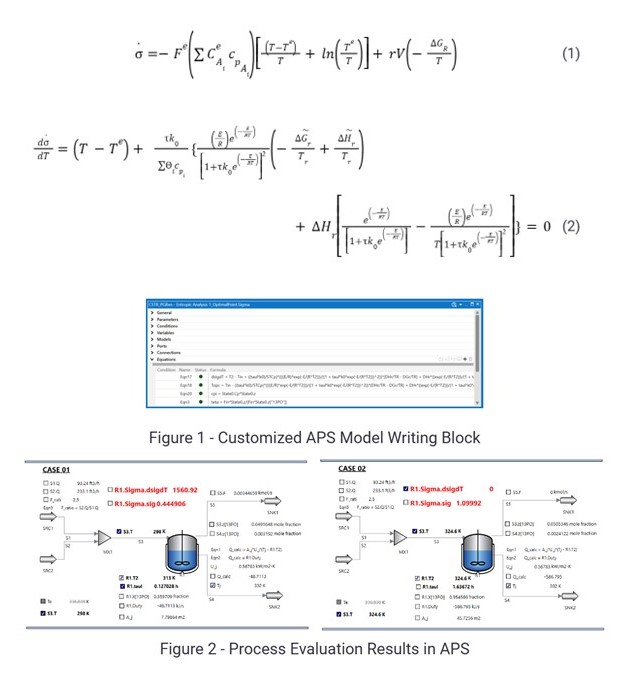

Several factors such as reaction temperature, pressure, residence time, and catalyst type have been investigated to optimize the process parameters and improve the product yield. So, in this work, the process of optimization has taken into account the mass, enthalpy, and entropy balances, allowing the entropy generation rate evaluation, as presented by Eq. (1). Assuming Eq. (1) is differentiable and a function of temperature (T), then, based on the more traditional optimization technique, the minimum value of it is obtained when the relationship, given by Eq. (2) is satisfied.

Based on Model Writing mode of APS, and taking into account the entropy generation rate minimization, a customized block, in Figure 1, has been created and used as an objective function. Then, the model block is used to calculate the entropy generation rate, considering the relation presented by Eq. (2), where the variables (Inlet temperature, residence time, and reaction temperature) are automatically adjusted to minimize the entropy generation rate. Such a procedure has allowed the process conversion improvement from 36% (Classical conditions - Case 01) to 95% (EGM conditions - Case 02), as presented in Figure 2.

Keywords: Entropy Generation Rate; Optimization; Thermodynamics.

References

Linnhoff, B., Hindmarsh, E. (1983), Chemical Engineering Science, 38 (5), 745-763

Rao, K. S., Reddy, K. S., Reddy, K. N. (2003), Energy Conversion and Management, 44(17), 2745-2758

Manzi, J., Brito, R., Bispo, H. (2011), Chemical Engineering Science, 66(3), 530-537

Bispo, H., Silva, N., Brito, R., Manzi, J. (2013), Energy Conversion and Management, 76, 26-31

Maximo, M., Bispo, H., Nilton, S., (2019), Chemical Engineering Communications, 206(9), 1241-1248

Bispo, H., Manzi, J. (2022), Chemical Engineering & Technology, 46(4), 785-793