2023 AIChE Annual Meeting

(397d) High Energy Ion Beams-Induced Tailoring Ultramicropores in Carbon Molecular Sieve Membranes for Hydrogen Separation

Authors

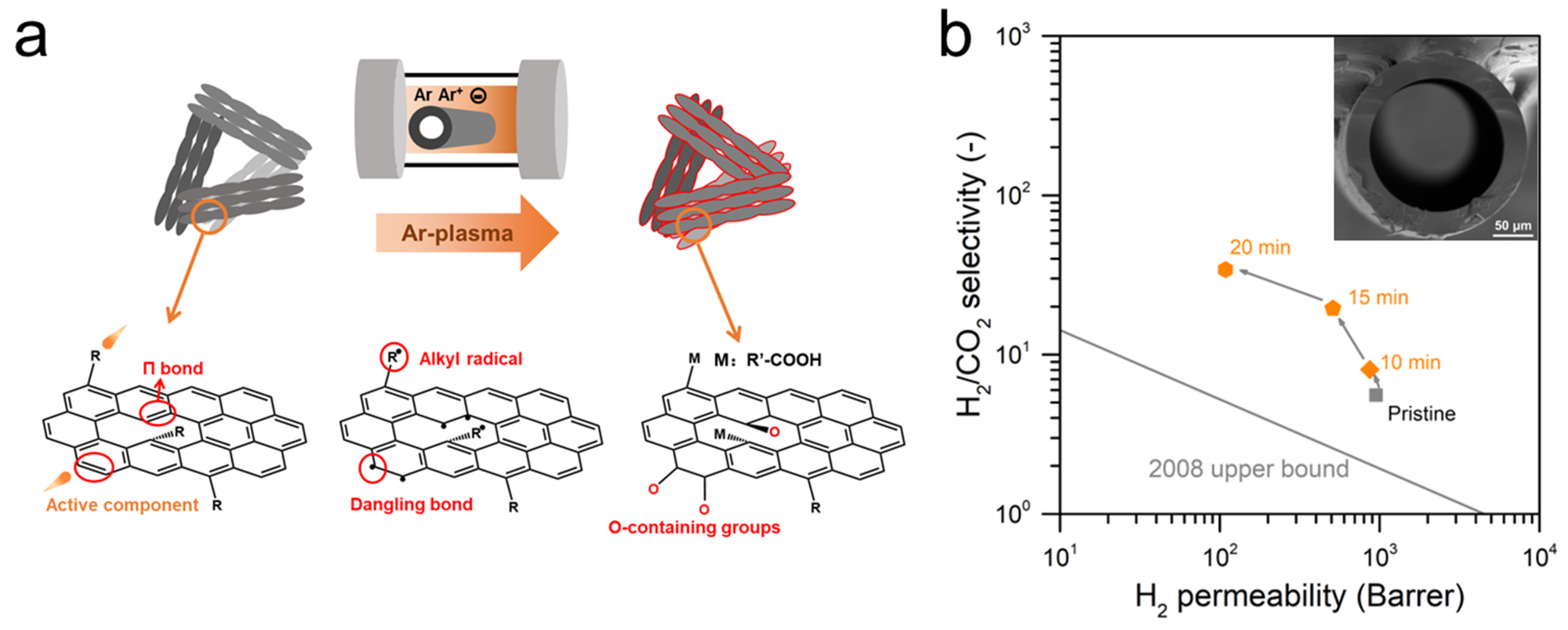

The CHFMs were prepared from bio-renewable material of cellulose. By employing a dry-wet spinning method, cellulose hollow fiber membranes were fabricated and were further carbonized in a tubular furnace to obtain CHFMs. The fresh CHFMs were then treated with Ar plasma radiations in a plasma furnace with tunable treatment time and power (Figure 1a). It was found the H2/CO2 selectivity of the membranes sharply increased from 5.2 to 30.8, when the Ar-plasma was applied to the CHFMs, which cross the 2008 Robeson upper bound limit (Figure 1b). Further microstructure characterizations, such as XPS and Raman spectrum, suggested that the high-energy argon ion beams could modify the surface of the CMS via oxygen-functionalization and tune the ultramicropores, resulting in precisely tailor separation performances. This research provides a potential way to design the microstructure of CMS membranes for the precise separation of challenging gas pairs.