2023 AIChE Annual Meeting

(252i) Interfacial Behavior of Anionic Surfactant, Biopolymer and Hydrophilic Nanoparticles with Heavy Crude Oil for Enhanced Oil Recovery Applications in Sandstone Reservoirs

Author

Rahul Saha - Presenter, National Institute of Technology Hamirpur

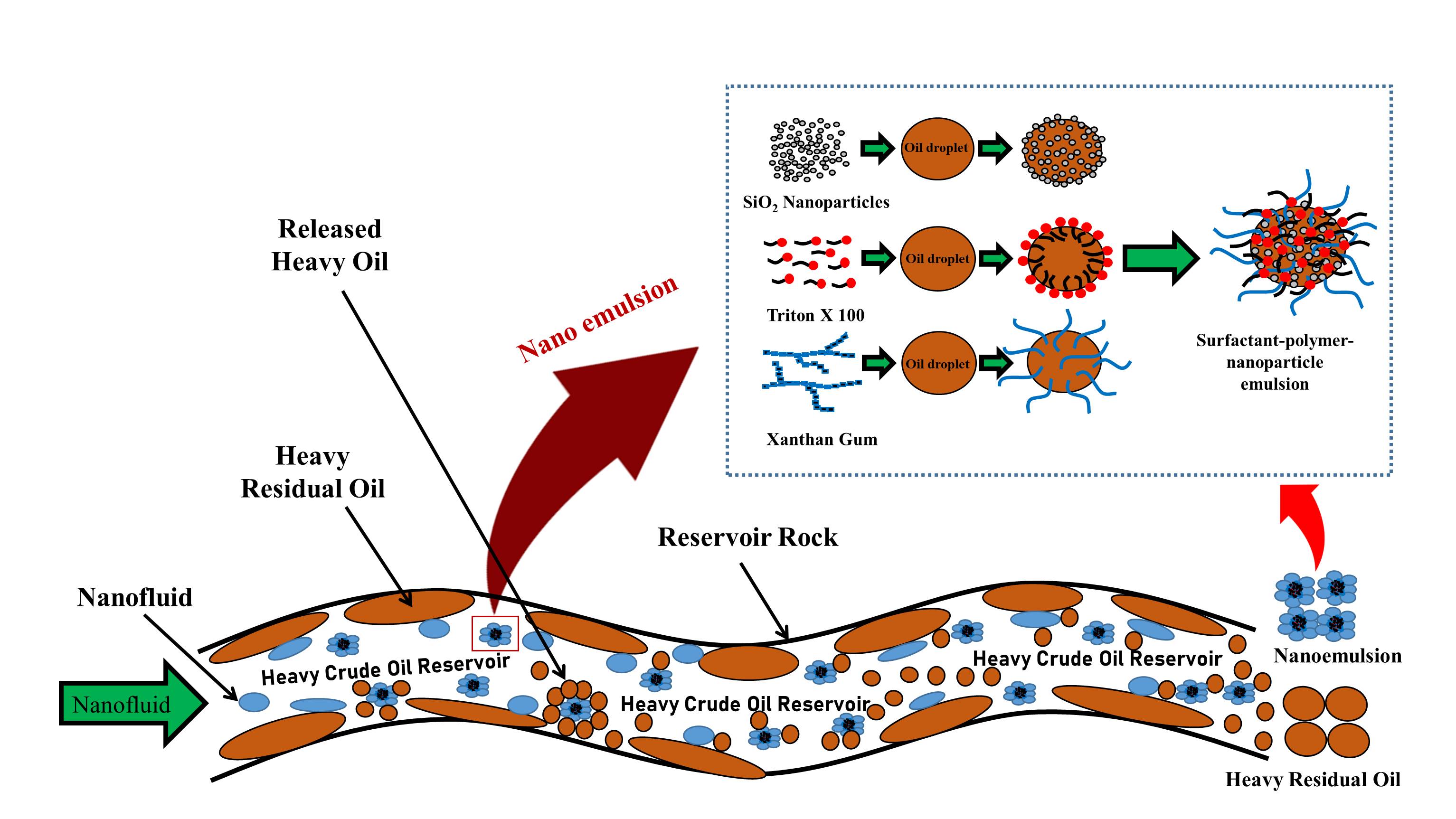

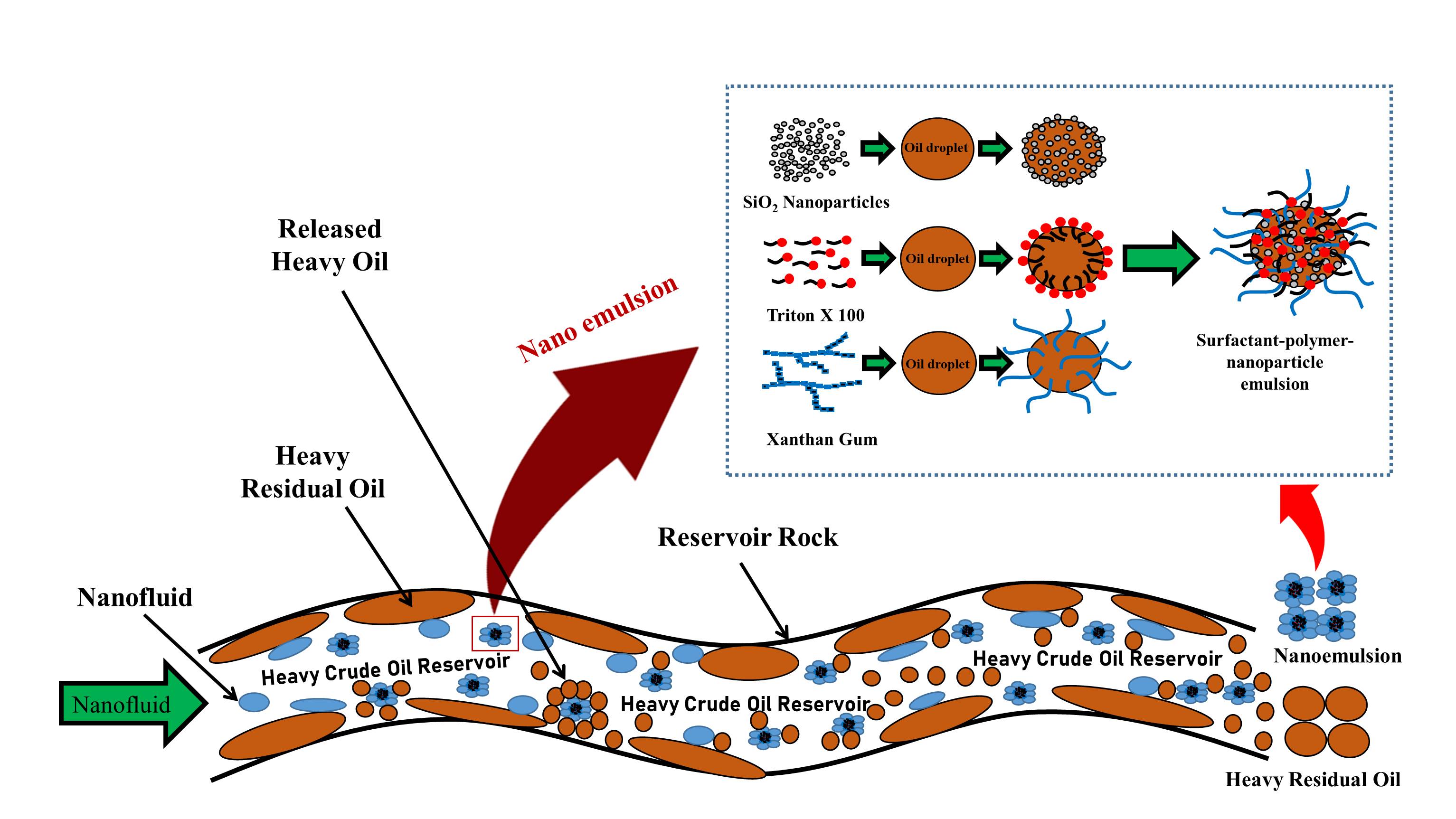

The demand of crude oil exploration from matured reservoirs is inevitable due to world energy demand. As the light category crude oil (easy oil) is exhausting, therefore the extraction of heavy crude oil from sandstone reservoirs is of prime focus. Thus, to enhance heavy residual oil recovery, nanofluids (surfactant-polymer-nanoparticles) flooding enhanced oil recovery schemes were investigated. Nanofluid flooding is an emerging trend in oil and gas industry however, their successful implementation in heavy oil reservoir is challenging due to severe complexities of the oil reservoirs system. Till today, no commercial successful nanofluid flooding has been executed or deployed in commercial oil field scale. Therefore, the existing condition conveys the importance of nanotechnology for oil recovery applications. In this work, a nanofluid formulation was developed with an understanding to recovery heavy oil from oil reservoirs. An initial screening of surfactant and polymers were executed based on the interfacial and rheological properties respectively. Numerous surfactants from anionic and non-ionic categories were tested and the surfactant which retains lower interfacial tension (IFT) along with emulsion formation capabilities with the heavy oil was selected for sandstone reservoir. Anionic surfactant (Triton X 100) showed lowest IFT behavior by reducing the IFT by almost 200 times. In addition, stable emulsion behavior was observed with Triton X 100 as compare to other surfactants which has the potential to improve oil displacement efficiency. Additionally, as Triton X 100 is non-ionic it can be deployed to reservoirs of any charge and is expected to more or less similar adsorption characteristics. Similarly, biopolymer Xanthan gum was considered based on its tolerant behavior for high saline and high temperature so that it can retain its rheological properties irrespective of extreme reservoir conditions. Nanoparticles SiO2 (hydrophilic) was chosen based on its ecofriendly nature and is also one of the commonly used nanoparticles. The dispersion stability of nanofluid solutions were examined by sedimentation, particle size analyzer and zeta potential analysis and further inspection for mechanistic investigation were carried out. The nanoparticles were unstable in aqueous phase and show more than 75% sedimentation in just one day however, in aqueous chemical (surfactant âpolymer) phase the nanoparticles were stable even after a week. The stability was further confirmed by negligible variation in average particles size value and zeta value of above ±30. The mechanisms as interfacial tension, interfacial packing of surfactant-polymer-nanoparticles, interfacial properties, emulsion, droplet size distribution, creaming rate, rheological properties, wettability change, displacement efficiency and flow of nanofluid in porous media of reservoir rock were scrutinized in detail. The superior interfacial tension reduction (24 mN/m to 3 mN/m), emulsion droplet size reduction (7 to 5 µ) confirming stable emulsion, lower creaming rate (Creaming Index ⥠80), viscosity enhancement (450 to 650 mPa s), drastic contact angle reduction (75o to 14o) due to higher disjoining pressure, and improved oil displacement validated by flooding experiments were all confirmed as optimum concentration of nanoparticles in the nanofluid solution was reached. Finally, core flooding experiments in sandstone berea cores resulted in an additional oil recovery of 28% at 30oC and 24% at 80oC. The higher pressure drop curve during flooding analysis indicated the formulation of oil bank and its corresponding oil recovery with additional adsorption of nanoparticles on reservoir rock pores.