Breadcrumb

- Home

- Publications

- Proceedings

- 2023 AIChE Annual Meeting

- Fuels and Petrochemicals Division

- Advances in Biofuels Production and Alternative Fuels II

- (200d) Renewable Blendstocks from Hazardous Industrial Wastes Via Hydrothermal Liquefaction

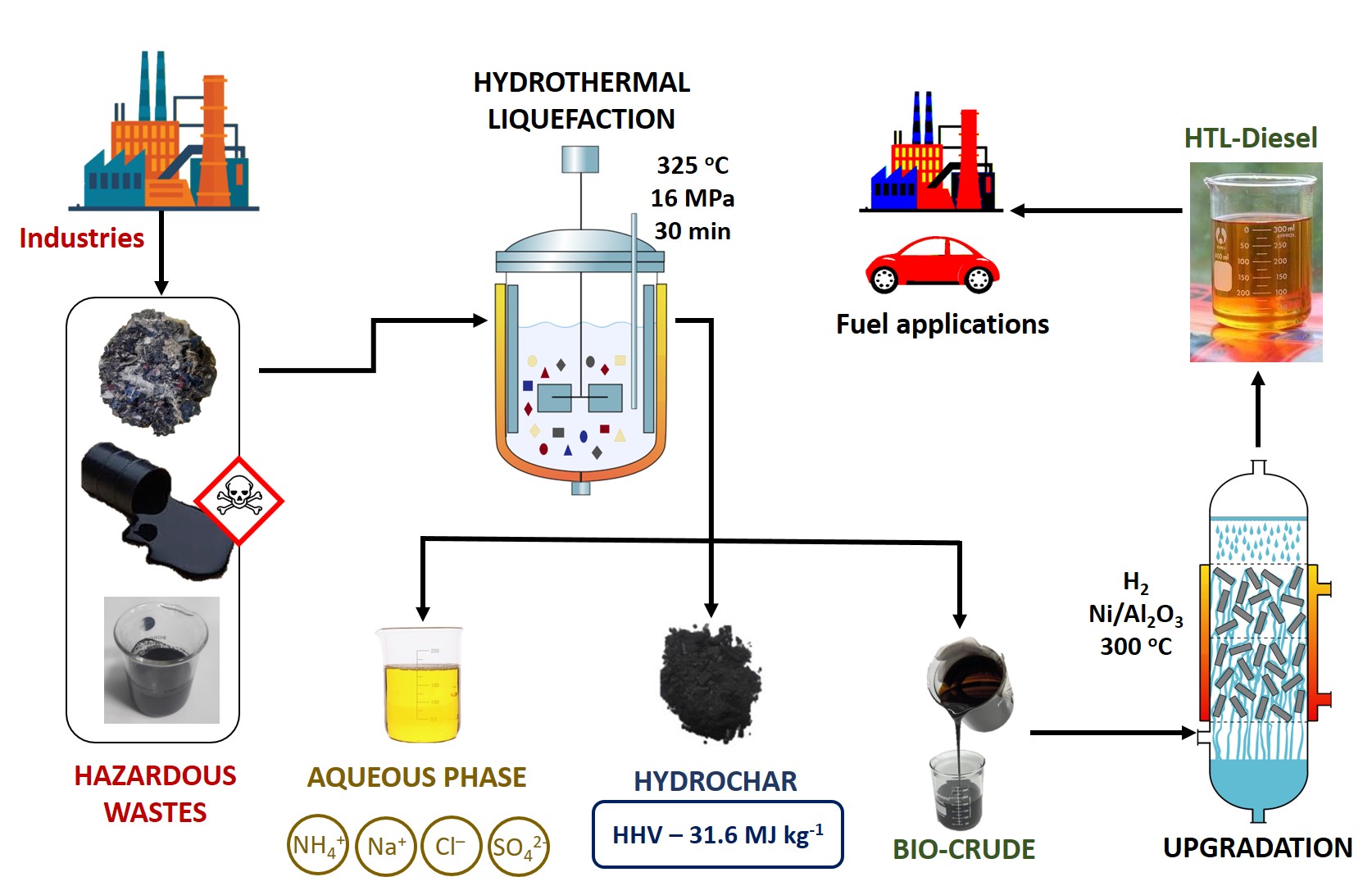

In this work, a mixture of hazardous wastes from a tube manufacturing plant in Chennai, India, which mainly consisted of grease-rich textile, soiled gloves, antirust chemicals, and lubricant oils, were co-liquefied in a 2L batch autoclave reactor, using the wastewater produced from the same manufacturing plant to produce diesel-grade renewable blendstocks. The mixture of wastes was classified into two major fractions, viz., textile wastes and chemical wastes, and hydrothermal co-liquefaction was carried out at 300 â 350 oC, for 30 min, by varying the feedstock composition (Textile: Chemical wastes â 100:0, 75:25, 50:50, 25:75, 0:100 w/w).

Results demonstrate that the yield and quality of the bio-crude were enhanced with the addition of chemical wastes. Maximum synergy in bio-crude yield was obtained for experiment with 75:25 w/w textile:chemical wastes, at 325 oC. The HHV of the bio-crude and bio-char from this condition reached 32.4 MJ kg-1 and 15.3 MJ kg-1, respectively, leading to an energy recovery of 92%. Ion chromatography of the aqueous phase revealed the presence of ions such as NH4+, Na+, Cl- and SO42-. The concentration of total ions in the aqueous phase drastically got reduced with the addition of chemical wastes, although the variation in operating temperature had little effect on the ion distribution in the aqueous phase. GC/MS results suggest that the major compounds in the bio-crude are long straight-chain hydrocarbons (~35%), long-chain carboxylic acids (~30%) and long-chain amides (~20%). In other words, upgrading this bio-crude to remove the O and N heteroatoms will lead to a renewable biofuel that is very close to that of petroleum crude in properties.

The bio-crude produced from 75:25 (textile:chemical wastes) at 325 oC was further upgraded, via desalting and hydrogenation using H2 and Ni/Al2O3 catalyst. The upgraded bio-crude was then distilled in the range of 150 â 380 oC to obtain HTL-diesel. The HTL-diesel was then blended with commercial diesel to produce renewable blend stocks. The blendstocks are then tested for their compatibility, efficiency and emission in an IC engine. Techno-economic analysis Considering the worldwide diesel consumption per day is nearly 4.5 billion liters, blending 10 vol.% of HTL-diesel produced from waste feedstocks with commercial diesel will save nearly $700 million worth of diesel every day.