In the alarming context of landfill of organic residues and the generation of greenhouse gases, it is important to develop more sustainable processes to use these residues to produce some renewable energy sources (e.g., biodiesel, ethanol and biogas, etc.). Biomethanation/AD is one the most promising solutions; it consists of a biological degradation of the biomass by living microorganisms in the absence of oxygen. Four steps are categorized in this process: hydrolysis, acidogenesis, acetogenesis, and methanation. the choice of the inoculum depends on the type of biomethanation: Psychrophilic (T=5-25°C), Mesophilic (T=35-40°C) or Thermophilic (T= 55°C). The generated biogas is composed of methane (50 to 75%), carbon dioxide (25 to 45%) as well as some traces of H

2S, H

2, N

2, NH

3. The biogas produced can be used for various purposes, e.g., injected into a gas network, used as a source of heat or electricity, used for the synthesis of other value-added chemicals, etc. The technology efficiency depends on the substrate nature; Because of their complex structure (35-50% cellulose, 15-25% hemicellulose and 10-15% lignin), the lignocellulosic residues require a pretreatment step to facilitate the penetration of microorganism, making the cellulose more accessible to the microbial action. Several pre-treatment technologies were tested in the literature: Chemical, physico-chemical and biochemical treatment technologies. However, none of the proposed methods is optimized yet to avoid excessive degradation with production of inhibitor compounds.

The present project aims to improve the management of lignocellulosic waste by developing new technologies whose aim is to increase the carbon conversion contained in this waste, and thus, increase the production of green products such as biomethane. The main idea consists in implantation of a pretreatment step with steam explosion unit preceding the anaerobic fermentation one. This technology is considered as a high temperature thermochemical process (> 200°C), which comprises the destruction and solubilization the biomass allowing a massive hydrolysis of its structure. The yield of biogas production and its composition will be studied according to several conditions of (1) pretreatment of biomass such as: Temperature, catalyst, and residence time in the steam explosion reactor, and (2) anaerobic fermentation conditions such as: Temperature (Psychrophile/Mesophile) Substrate/Inoculum ratio, HRT, OLR.

The lignocellulosic biomass used in this work consists of wood chips (< ¼ inch) from resinous agroforestry residues (spruce) from the Estrie region of Quebec. CANADA. Its composition in sugars, acids, furfural, and 5HMF is measured by an HPLC chromatography. Heavy metals and cations are measured by Inductivity coupled plasma mass spectroscopy ICP-OES. The anaerobic digestion of the pretreated biomass is carried out in a serie of bioreactors operated at mesophilic/psychrophilic conditions. The monitoring of biogas production is done by a manometric method by estimating the volume of biogas produced inside each reactor. The composition of the collected biogas is analyzed by GC (gas chromatography).

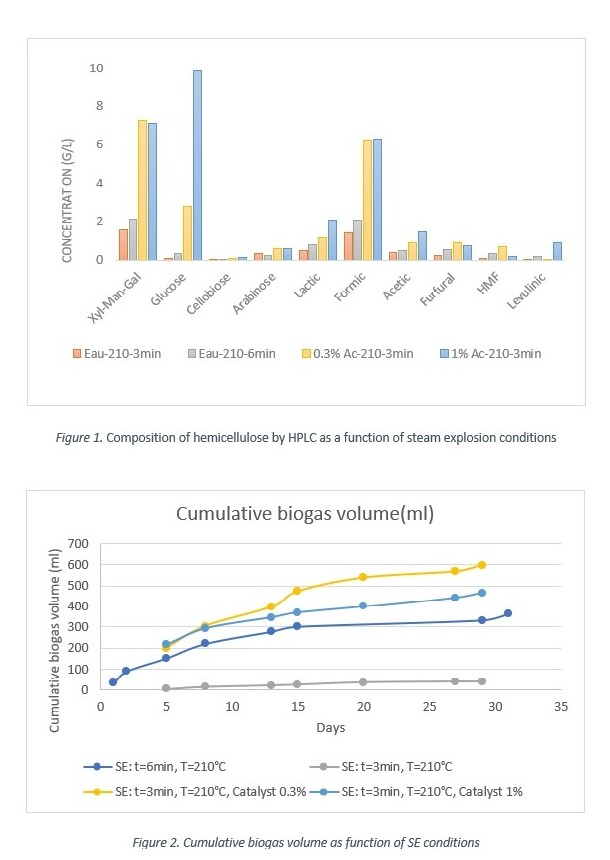

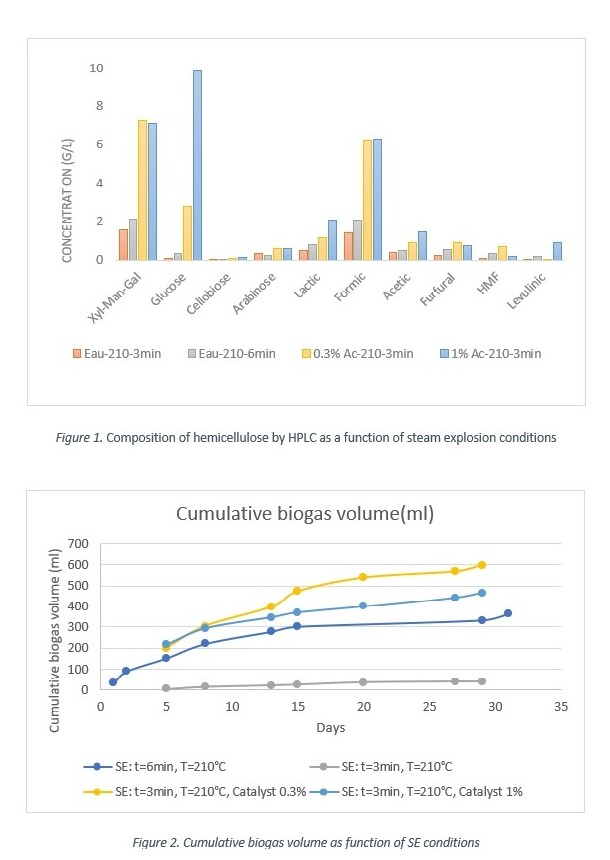

The HPLC and ICP-OES results demonstrate the destruction of the biomass and inhibitors production from the degradation of cellulose and hemicellulose. The cellulose degradation releases glucose molecules, which produces 5-HMF. Similarly, hydrolysis of hemicelluloses produces xylose, arabinose, mannose, galactose, rhamnose and acetic acid. In general, at high temperature and high pressure, hexoses (C6) react like glucose to form 5HMF, and pentoses (C5) produce furfural. However, when the humidity is present, the hydration of 5HMF leads to an unstable tricarbonyl intermediate decomposing into levulinic acid and formic acid by hydration. The same samples were used as a substrate for anaerobic fermentation, for 30 days. The important production is showed with using a catalyst at low concentration 0.3%. However, at higher catalyst concentration, the biogas production declines. Without catalyst, the time of SE reaction positively influences the production.

This project is part of the energy transition efforts to respond to the problems of landfill of organic waste. Indeed, the degradation of organic residues generates greenhouse gases including methane and carbon dioxide, responsible for global warming. The scientific relevance of this work is the first attempt aiming to efficiently valorize the residual lignocellulosic biomass by coupling two known processes Steam explosion and Anaerobic digestion SE/AD for sustainable biogas production.