Heterogenous catalysts are the backbone of the chemical industry. Extrusion is one of the main industrial methods used to shape many of the established commercial catalysts. Commercial catalysts are available in different shapes and sizes that include cylindrical, trilobed, and quadrilobed for pelleted type catalysts, while for structured catalysts, the monolith type is the most established one. Additive Manufacturing (AM) offers a significant potential to explore new unconventional catalyst designs to achieve process innovation. Many additive manufacturing techniques are recently developed for a wide range of different materials and applications. Of these different AM techniques, robocasting is a very promising technique to manufacture heterogeneous catalysts

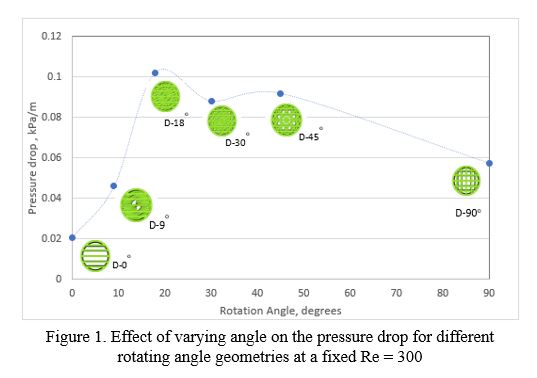

1. It is based on the well-established extrusion process but utilizes the principle of additive manufacturing in which extrusion is made in a layer-by-layer structure. In this work, new unconventional 3D-printed catalyst designs that are not possible to produce using conventional extrusion techniques are benchmarked against the well-established monolith catalyst structure. The basic idea for these new designs is to rotate the new layer as the extrusion is progressing. Six (6) new designs are created with rotational angles of 0

o, 9

o, 18

o, 30

o, 45

o, and 90

o. To prove the manufacturing feasibility of these geometries, the designs were fabricated using a benchtop robocasting machine. The performance difference between these catalyst geometries was numerically investigated using Computational Fluid Dynamics (CFD) using COMSOL. This is a good starting approach to evaluating novel catalyst designs

2. The momentum equation was used to simulate the velocity profile and the pressure drop between these geometries. Steam methane reforming to produce synthesis gas is used as an application case to demonstrate the difference between these geometries. A comparative table is created to benchmark these geometries. Geometry D-0

o gave the lowest pressure drop, while D-18

o gave the highest. Geometry D-18

o, D-30

o, and D-45

o gave the highest degree of radial mixing. Geometries D-90

o and D-9

o gave a compromise between lower pressure drop with some degree of radial mixing. This work is a step in the direction of exploring how AM can generate tailored and novel catalyst-shaped designs.

(1) Lawson, S.; Li, X.; Thakkar, H.; Rownaghi, A. A.; Rezaei, F. Recent Advances in 3D Printing of Structured Materials for Adsorption and Catalysis Applications. Chem. Rev. 2021, 121 (10), 6246â6291. https://doi.org/10.1021/ACS.CHEMREV.1C00060/ASSET/IMAGES/LARGE/CR1C0006….

(2) Asif, M.; Grande, C. A. TPMS Contactors Designed with Imprinted Porosity: Numerical Evaluation of Momentum and Energy Transport. Ind. Eng. Chem. Res. 2022, 61 (50), 18556â18566. https://doi.org/10.1021/acs.iecr.2c03384.