2022 Annual Meeting

(80e) Predicting the Effect of Particle Shape on Random Packing: The Case of Nonequant Shapes

Authors

The packing behaviour of granular materials is relevant to a variety of fields, for example filtration1, packed beds2, materials processing3, to name a few. In all these applications, the accurate prediction of random packing structures based on a population of particles can facilitate more efficient processes, in terms of both the energy consumption and the productivity. For example, in filtration a low void fraction leads to a greater filter cake resistance, causing high pressure drop, and long filtration times.

The structure of a random packing of an ensemble of particles is affected by various factors, including surface properties, size distribution width, and particle shape. Previous work relating particle shape to packing densities has considered basic primary shapes4, (e.g. spheres, cubes), as well as different convex and concave shapes5 (e.g. stellated octahedra, tetrapods). A recent report has demonstrated the use of Monte Carlo simulations to predict the void fraction of packings of elongated particles of varying aspect ratio6. Despite the progress, several challenges related to the use of such models still exists, including the consideration of more complex shapes and more importantly their independent experimental validation.

The overarching goals of this work are (i) the systematic experimentally investigation of the effect of shape on packing in terms of aspect ratios, allowing for equant, elongated, plate-like particles, and everything in between; and (ii) the development of a model capable of predicting and explaining the porosity and packing structure for all the aforementioned shapes.

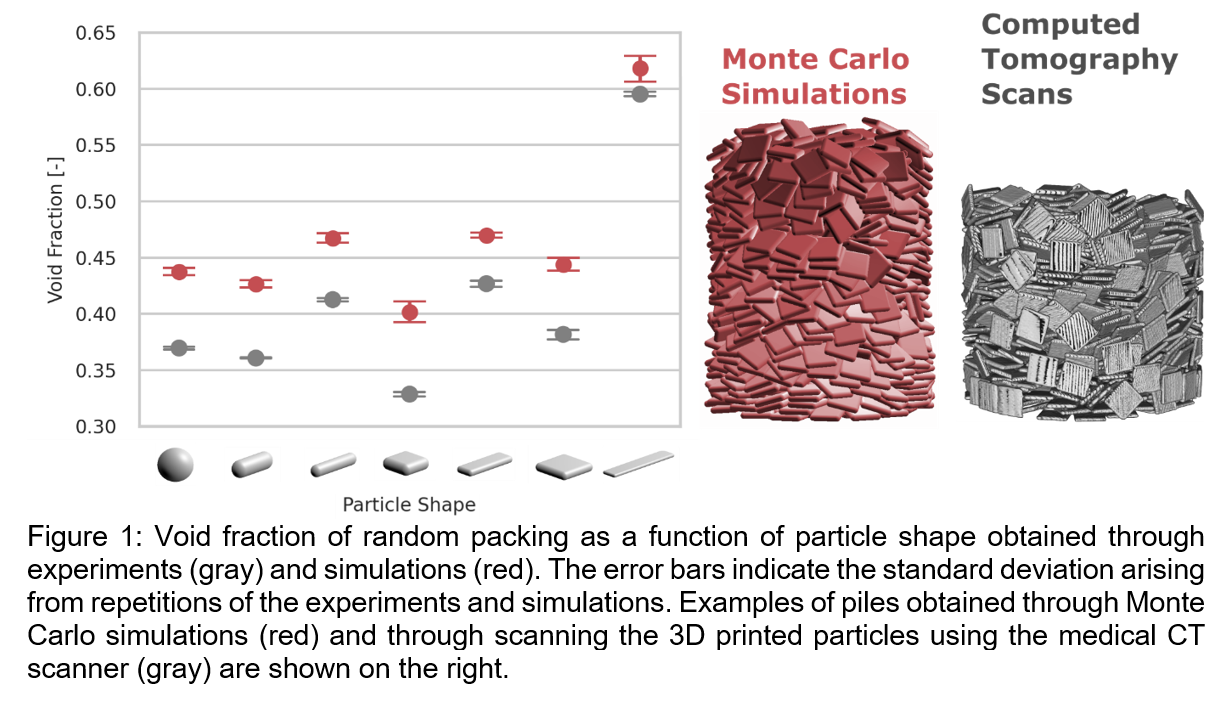

Here, we describe the development of a Monte Carlo framework to simulate the settling of particles of different sizes and shapes into a container. The settling process is simulated through stochastic, but preferentially downwards movement. Subsequently, we check if the particleâs new position and orientation leads to intersection with other particles in the vicinity, the floor or the wall of the container. For computational efficiency, in the simulations we assumed all the particles to be spherosimplices. We considered several populations that have different aspect ratios (as shown in Figure 1).

We validate the trends observed in the Monte Carlo simulations through a systematic experimental campaign. To this aim, we use monodisperse 3D printed particles with the same shapes as the ones used in the simulation. In the experiments, the 3D printed particles were poured into containers and subsequently imaged with a medical computed tomography (CT) scanner, which was previously used for related purposes7. We developed an image analysis pipeline to extract quantifiable packing metrics from the tomographs. These metrics include the overall void fraction of the packing, vertical and radial porosity profiles, and particle orientations.

We performed several experiments to study: (a) the effect of the wall of the containers; (b) the repeatability of measurements; (c) the effect of tapping/vibrating the particles in the container; and (d) the effect of mixing particles of different shapes.

Based on the experimental and the computational outcome shown in Figure 1, we make two important observations. First, we observe that the porosity of the packing depends on the particle shape. Second, we show that the experimental data are in good qualitative agreement with the outcome from Monte Carlo simulations, despite the absence of any model parameter tuning. For all the particle shapes, the void fraction is slightly overestimated, the error being less than 0.05 in absolute terms. Additionally, we have also made other observations which are not shown here. First, as expected, vibration leads to a higher reduction in void fraction when applied to higher aspect ratio particles. Second, the magnitude of the wall effect depends on the particle shape. Third, the void fraction of populations with mixed particle shapes are averages of their corresponding constituent shapes.

To conclude, this work has led to a number of outcomes. First, we have a model that can qualitatively predict the packing behaviour of nonequant particles. Second, we have found a non-trivial dependence of packing behaviour (including the overall void fraction of poured and vibrated piles, and the wall effect) on the aspect ratio. In the future, this model can be used in a variety of real-world settings (e.g. pharmaceutical production chain) to reduce the experimental effort to determine packing behaviour.

References

[1] Murugesan, S., Sharma, P. K., & Tabora, J. E. Design of Filtration and Drying Operations. Chem. Eng. Pharm. Ind. R&D to Manuf. 2010

[2] Achenbach, E. Heat and flow characteristics of packed beds. Experimental Thermal and Fluid Science 1995, 10(1), 17â27

[3] Dinger, D. R., & Funk, J. E. Particle-packing phenomena and their application in materials processing. MRS Bulletin 1997, 22(12), 19â23.

[4] Li, B., Zhang, H., Saranteas, K., & Henson, M. A. A rigid body dynamics model to predict the combined effects of particle size and shape on pressure filtration. Sep. Purif. Technol. 2020, 119462.

[5] Landauer, J., Kuhn, M., Nasato, D. S., Foerst, P., & Briesen, H. Particle shape matters â Using 3D printed particles to investigate fundamental particle and packing properties. Powder Technol. 2020, 361, 711â718.

[6] Perini, G., Avendaño, C., Hicks, W., Parsons, A. R., & Vetter, T. Predicting filtration of needle-like crystals: A Monte Carlo simulation study of polydisperse packings of spherocylinders. Chem. Eng. Sci. 2021, 230, 116151.

[7] Pini, R., & Madonna, C. Moving across scales: a quantitative assessment of X-ray CT to measure the porosity of rocks. J. Porous Mater. 2016, 23(2), 325â338.