2022 Annual Meeting

(577f) Electrochemical-Mechanical Microstructure-Scale Battery Modeling for Improved Performance and Degradation Predictions during Fast Charging.

Authors

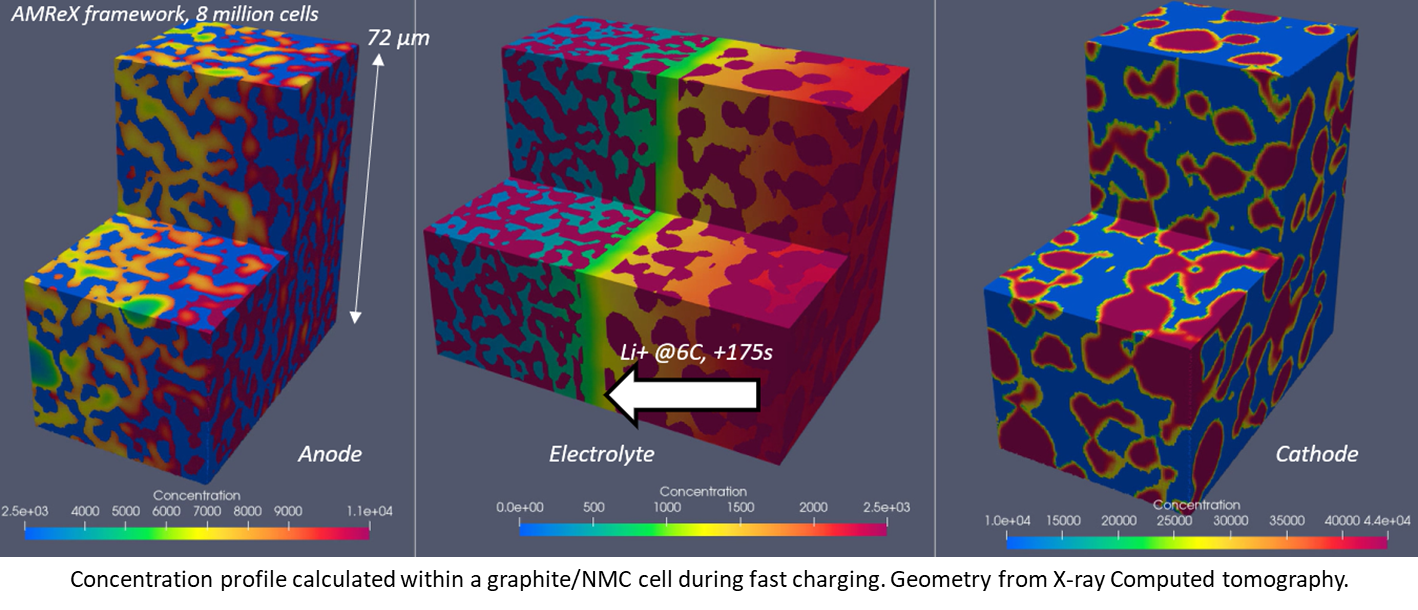

Microstructure-scale models remedy these limitations by directly solving the governing equations on the electrodeâs constituent geometry [2]. Electrode materials for lithium-ion batteries have complex microstructure geometries that require millions of degrees of freedom to solve the system at the microstructure scale and be representative. In this work [3], a microstructure-scale coupled electrochemical-mechanical model is developed. The solver uses a level-set method for modeling electrode-electrolyte interfaces and surface reactions. It is built on a block-structured adaptive-mesh-refinement framework using open-source library, AMReX [4], and can currently utilize emerging heterogenous (CPU+GPU) computing architectures. This approach simplifies mesh generation for complex microstructure geometries and leverages fast and scalable multi-grid based linear solvers on Cartesian grids. Simulations of fast charging for automotive application, with electrode geometries obtained through Computed-Tomography imaging are presented (cf. figure below). Concentration gradients, in-plane heterogeneities, cell-voltage and potential for lithium plating are discussed and compared with a baseline macroscale model. In addition, stress distribution is analyzed within the electrode volume. The model demonstrates excellent mass conversation and high numerical scaling efficiency on high-performance computers (HPC), both for CPU and GPU architectures.

[1] F. Usseglio-Viretta et. al., Journal of The Electrochemical Society,165(14) A3403-A3426 (2018), https://doi.org/10.1149/2.0731814jes

[2] J. Allen et al., Journal of Scientific Computing, 86:42 (2021), https://doi.org/10.1007/s10915-021-01410-5

[3] Article in preparation.