Rising global energy demand and rapid depletion of fossil fuel reserves are driving the search for alternative energy resources. Recently, there has been an increasing interest in using lignocellulose biomass as a sustainable feedstock for fuels and value-added chemicals, resulting in valuable fuels mostly with zero CO

2 emission. Ethylene glycol (EG) conversion is relevant for hydrogen and syngas production. Platinum is the most effective catalyst for this process due to its synergistic features of high dehydrogenation and high selectivity to CâC bond scission activities; however, it is economically intensive. The use of bimetallic catalysts for biomass feedstock refining is an intelligent technique because the interaction between metals can alter the surface properties of the catalyst. These modifications can greatly enhance catalytic activity, alter selectivity to the targeted products, and boost catalyst stability in the presence of biomass-derived impurities and harsher reaction conditions. In this study, we investigated the mechanism of EG decomposition for hydrogen production on Pt (111) and Pt

3Sc (111) from first-principles calculations. We reported the various barriers and reaction energies by exploring all the 63 elementary reactions involve and developed microkinetic models that elucidate the vapor phase kinetic data for the process.

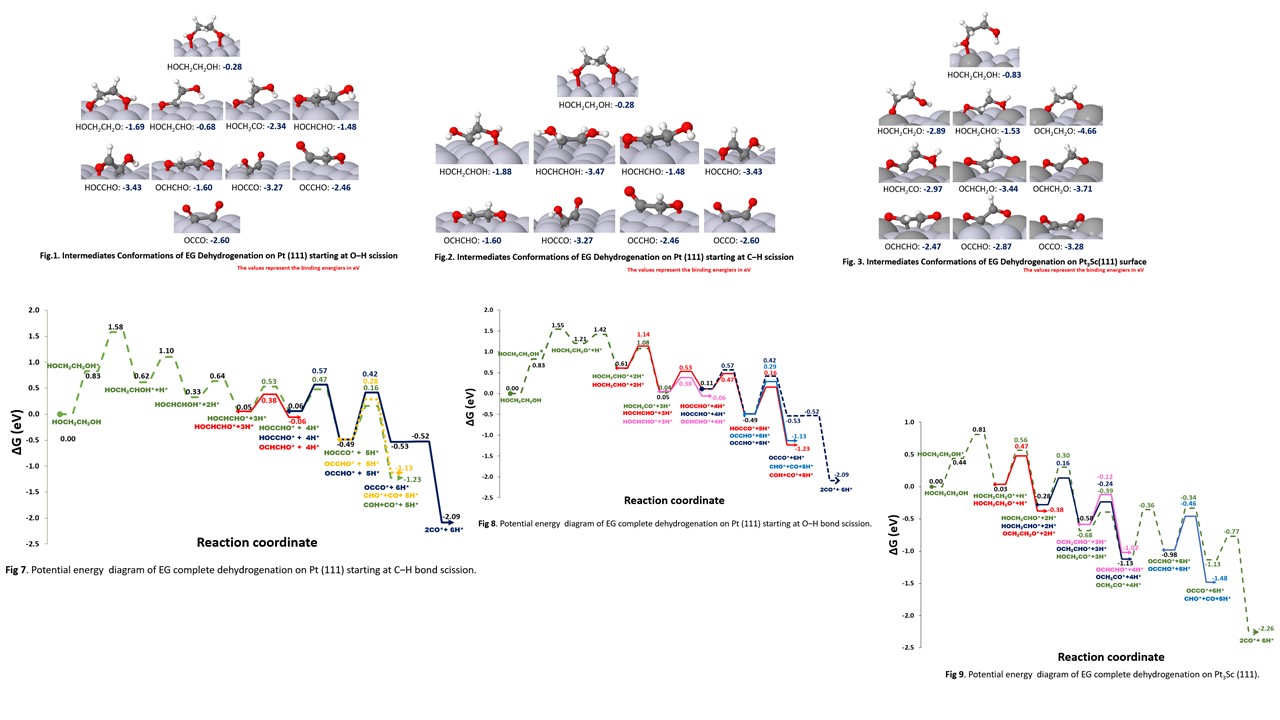

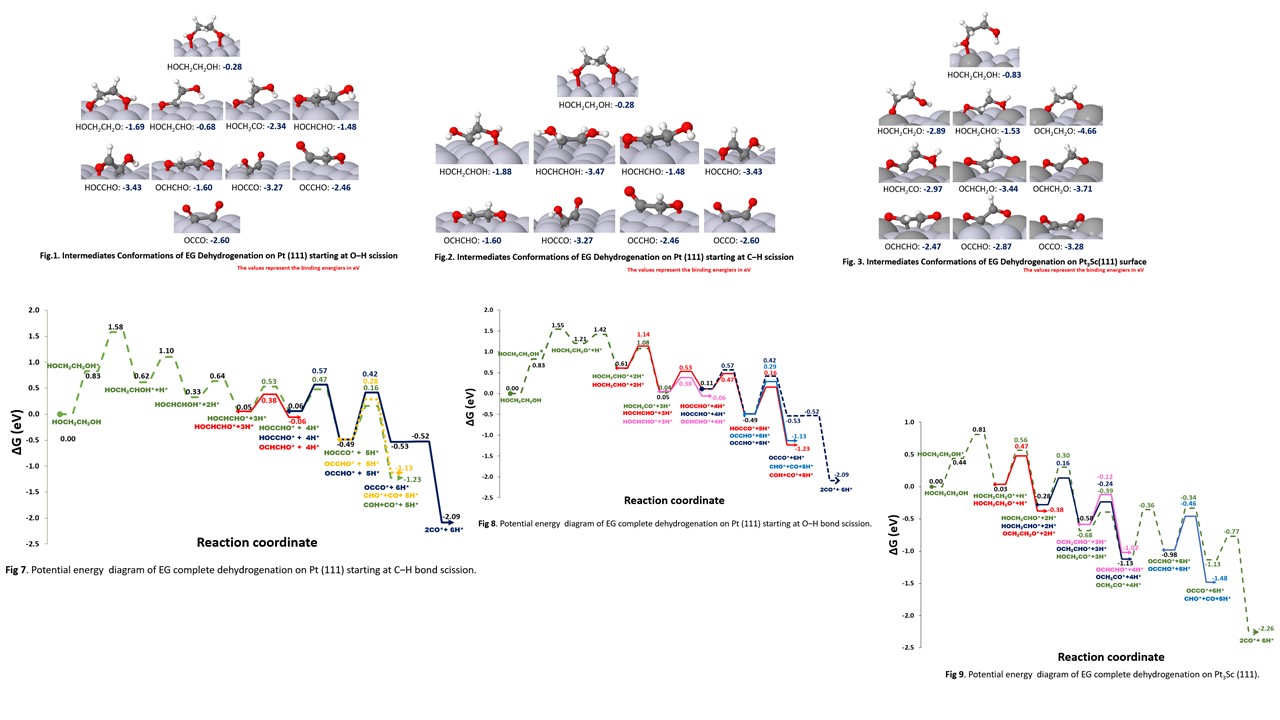

Furthermore, we presented the minimum energy pathway (MEP) on Pt (111) and Pt3Sc (111) with the aid of potential energy diagrams (PEDs). Finally, we compared the activities of both catalysts and demonstrated how Pt3Sc (111) outperformed Pt (111) in terms of the MEP barriers. Our results revealed that on Pt (111) surface, EG dehydrogenation underwent a competitive pathway starting either at CâH or OâH bond scission as obtained from the almost similar Gibbsâ free energy barrier of the first stage dehydrogenation process. However, on Pt3Sc (111) surface, EG dehydrogenation conspicuously commenced with OâH bond scission with a very low barrier and proceeded until complete dehydrogenation was achieved.

The results of the dehydrogenation pathways on both surfaces are presented in Fig. 1 via Fig. 9, and the parameterization for the microkinetic studies is shown in Tables 3 and 4.