2022 Annual Meeting

(410f) Developing a Process Analytical Technology for Particle Size Determination in Twin Screw Granulation Using Acoustic Emissions

Authors

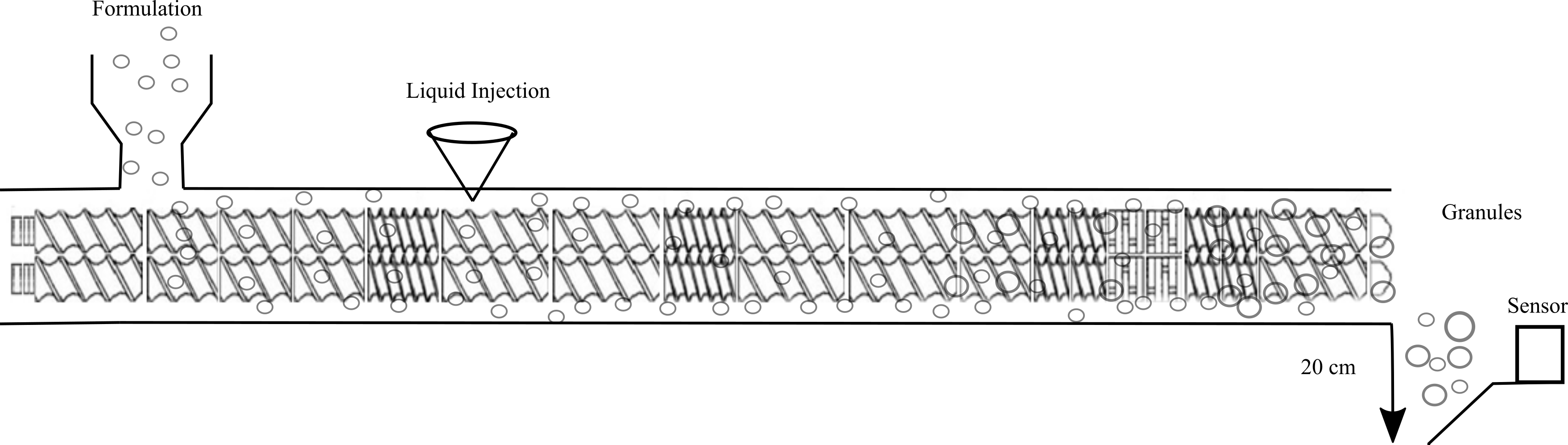

METHODS: Flowlac 100 lactose monohydrate powder (Meggle GmbH) was granulated in a 27 mm 40 L/D co-rotating twin screw extruder (Leistritz Advanced Technologies Corp.) with METHOCEL E3PLV (International Flavour and Fragrances Inc.) as the aqueous binder. An stainless steel impact plate was placed 20 cm below the exit of the extruder with an attached broadband AE sensor (Mistras Group) to record particle impacts. Multiple setup configurations for the plate were examined, looking at thickness (0.7, 1.0, and 1.5 mm) and angle of inclination (10-60°), with particle collisions recorded with a FASTCAM SA-Z type 2100k high speed camera (Photron Limited) at 20,000 frames per second to arrive at an optimal system.

The optimal acoustic sensor-plate configuration was used to record particle collisions for granules exiting the extruder at liquid-to-solid (L/S) ratios of 8-14% to produce PSD with differing amounts of fines (<300 µm), coarse particles (>2000 µm), and suitable sizes for tableting (600-1500 µm). The collected granules were characterized using a sieve shaker to determine the weight fractions of the PSD from 49 to 7150 µm. The AE signal was pre-processed by applying a discreet Haar wavelet filter followed by a fast Fourier transform to view the signal in the frequency domain. For the wide range of particles dropping onto the plate, auditory or spectral masking complicated the analysis by the model. To address this issue, a digital impact signal filter was conceived to alleviate auditory masking at the impact plate, derived from Hertz theory for single particle impacts.

An artificial intelligence neural network (ANN) model was created to relate the frequency domain spectrum to a PSD. The model architecture consisted of one input layer, three hidden layers, followed by one output layer. The model had activation functions of the Rectified Linear Unit for the input and first hidden layer. The second and third hidden layers had the hyperbolic tangent and sigmoid functions, respectively, while the output layer had a linear activation function. The root mean squared error (RMSE) was used to quantify the prediction error. Data from the multiple experimental trials with the extruder for each L/S ratio, were split into 80% training and 20% testing sets. Stratified splitting was employed to ensure the training and testing sets contained an equal proportion of data for each L/S ratio.

RESULTS: Trials examining the effect of inclination angle for the plate found that 60° (relative to the horizontal) was ideal. At angles below 45°, the AE signal should have been stronger due to a higher normal force attributed to a collision; however, due to mass accumulating on the surface of the plate, the signal was actually dampened. High speed camera images showed a significant amount of granular damage at 45°, associated with the normal force of collision. At 60° the decreased normal force in particle impacts reduced the damage observed and the granules departed the collision site by sliding/rolling with little detectable secondary impacts.

Increasing the plate thickness reduced the signal amplitude but did not affect the frequency information within the signal. At lower thicknesses, particle impacts caused detectable vibrations of the plate itself and seemed to increase the likelihood of secondary collisions by the granules. Increasing the thickness to 1.5 mm reduced these vibrations, making it the preferred thickness for the setup.

Prediction errors for the ANN model showed that use of the digital impact signal filter significantly improved the accuracy, from a maximum deviation of 4.2 wt% to 1 wt% for all particle sizes. Much of the error was localized around the particle size fraction at 2230 µm. After the digital impact signal filter was applied to the AE data, the loss error was no longer localized around 2230 µm, highlighting the negative effect that auditory masking was having on the AE signal in the original model. Diminishing auditory masking of the signal allowed the model to more equally consider the contribution of all frequencies (and their related particle collisions) in the predictions.

CONCLUSIONS: A robust approach for PAT based on ultrasonic acoustic emissions has been successfully found to monitor the complex bimodal particle size distribution attributed to continuous twin-screw granulation. This preliminary study for the AE-based PAT approach was trained with lactose monohydrate, whereas future studies will report on the relevance of different excipients and their individual nature of hydration on the acoustic emissions of impacting granules.