2022 Annual Meeting

(2ad) Developing a Sustainable and Scalable Platform of High-Performance Degradable Polymers

Author

Research Interests

I am interested in developing industrially relevant technologies for the production of sustainable chemicals, with a focus on polymers. Along these lines, I want to develop a renewable carbon valorization laboratory where we work to create valuable chemicals from lignocellulosic biomass, plastic waste, and CO2. In this laboratory I would combine my extensive experience as both a chemical engineer and a polymer chemist to drive formulation of novel materials using chemicals that can be produced in high yields on scale from abundant and sustainable feedstocks. One of the key aspects of the laboratory would be creating high-performance materials, that are recyclable or degradable by design, to contribute to the future circular plastics economy. By the completion of my PhD in 2023, I will have had over 10 years of extensive technical experience in bio-chemical production as well as in polymer chemistry and plastic processing (outlined below). As co-inventor of a new class of polymer precursors for high-performance degradable plastics that can be easily produced from non-edible biomass (see the attached Nature Chemistry publication), I have a niche area of expertise to leverage. This technology is in its infancy and can be expanded to create an entirely new platform of sustainable sugar-based polymer precursors at low cost that can be used in a wide range of applications. In order to further distinguish my lab from other groups, I am looking for a post-doc opportunity in an orthogonal field. Specifically, I would like to expand my polymer chemistry skillset, particularly to include the synthesis and characterization of advanced thermosets and composites. In this way, I could couple this knowledge with the technologies I have already developed to create a research group centered around developing renewable monomers for low-cost degradable/recyclable thermosets and composites, which is currently a major challenge.

The creation of such a laboratory is enabled by my extensive and diverse experience developing processes to produce bio-based fuels, chemicals and materials. During my undergraduate studies in chemical engineering and biochemistry I worked for three years under the supervision of Prof. Danny Schnell to genetically engineer photosynthetic pathways in a biofuel crop to enhance carbon flux from CO2 to seed oil. There, I learned a number of biochemical and molecular biological techniques to engineer metabolic pathways, analyze the resulting changes in gene expression and metabolic flux, and measure the physiological responses in large field trials. I then moved on to work as technician for two years in the National Bioenergy Center at the National Renewable Energy Laboratory (NREL) with Dr. Gregg Beckham where I developed and patented cost-effective separation techniques for isolating bio-derived chemicals from lignocellulosic streams, which is often a major driver in biochemical selling prices. In this role, I published as a co-first author in Green Chemistry. I also contributed as a co-author on a wide variety of publications, including an article in Science. Through my work at NREL, I became experienced in working with large multidisciplinary teams to develop cost-effective processes and honed my skills as a separations engineer.

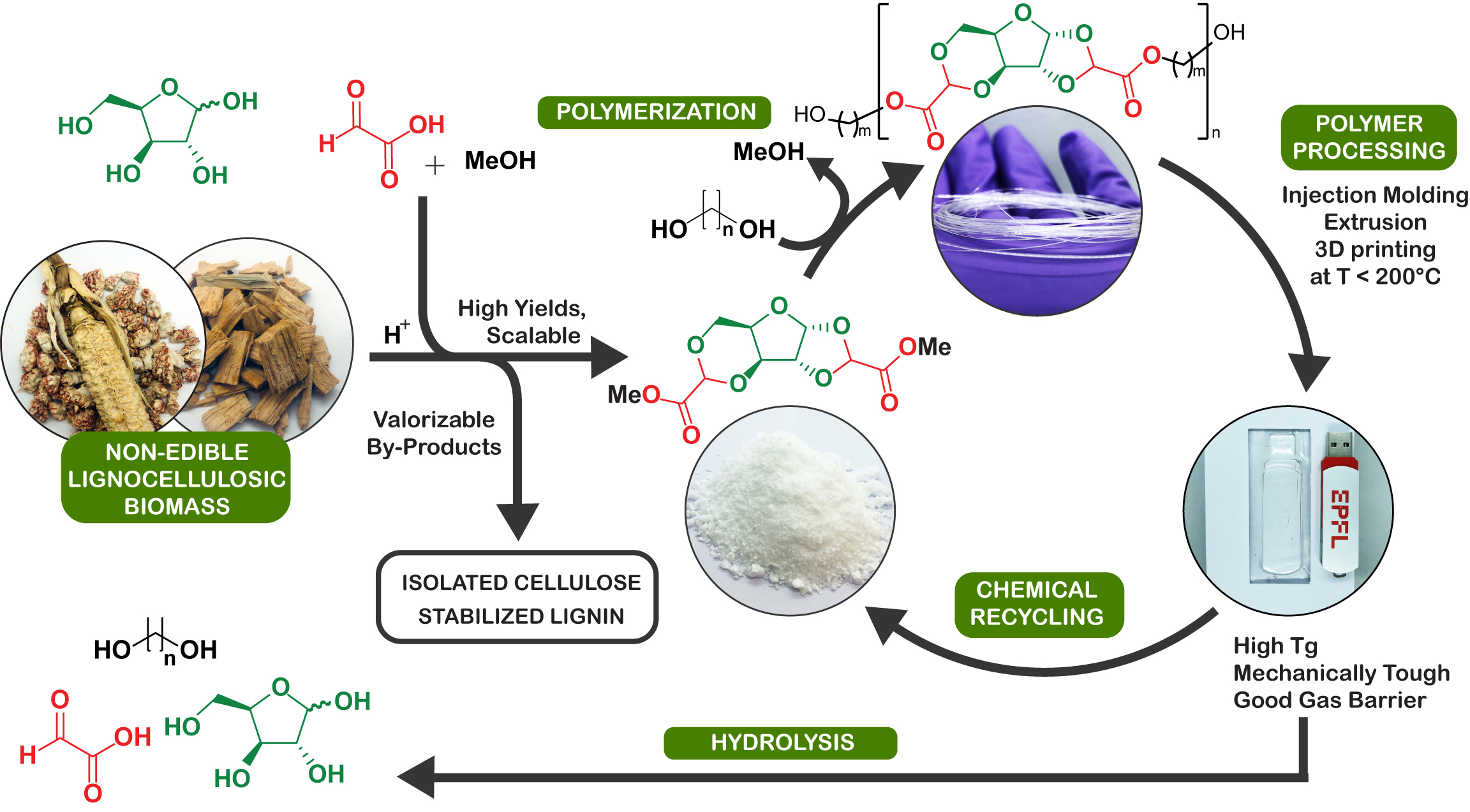

Deciding from these experiences that I wanted to lead the development of new sustainable processes, I elected to pursue my doctorate in Chemistry and Chemical Engineering in the Laboratory of Sustainable and Catalytic Processing (LPDC) at EPFL with Prof. Jeremy Luterbacher. During my doctorate, I co-invented a novel class of bioplastic precursors and developed a chemical process to produce them from non-edible biomass in high yields using a scalable process. I then polymerized this bio-derived monomer into a new class of performance polyesters with properties competitive with PET. To demonstrate useful plastic products, I formed a collaboration with the Laboratory for Processing of Advanced Composites at EPFL where I was able to process the plastics via extrusion, thermoforming, and 3D-printing. After a useful product lifetime, I demonstrated their cost-effective chemical recycling or degradation back to sugars via hydrolysis. I published this work as first author in Nature Chemistry and patented the technology. I am now a consultant for Bloom Biorenewables Ltd., which has licensed my patent and is in the process of commercializing the plastic. From this consultancy, I learned a great deal about what it takes to scale a chemical process and to bring a novel material to market.

I am now preparing two more high-impact scientific manuscripts where I have expanded the scope of this technology to other types of materials, including a novel class of high performance, transparent polyamides. In parallel, I am also leading a polymer subgroup (2 PhD students, 2 Masters students, and 3 apprentices) that is collectively working to further expand this renewable monomer platform I have invented, and am aiding in the drafting of grant proposals to bring in funding for these projects. From September through December 2022, I will be working as a visiting PhD student in the Green Materials Laboratory at the University of Manchester with Prof. Michael Shaver to gain a more in-depth experience in industrially-relevant plastic processing and additive engineering which I believe will be key to bringing sustainable materials to market. Overall, I believe my extensive and diverse technical background and my experience in leading research projects has prepared me to lead a research group of my own in the field of sustainable polymers.

Teaching Interests

I am highly motivated to teach. I started as a teaching assistant (TA) during my undergraduate degree and have been the TA for a graduate-level heterogenous reaction engineering course at EPFL for the past 3 years, during which I have given lectures to classes of over 40 students. I was also the head teaching assistant for the graduate level practical chemical engineering laboratory at EPFL for which I received the Teaching Excellence Award. Lastly, I have mentored two Masters students, two PhD students and have contributed to the education of 3 Swiss laboratory apprentices (technicians). I would be thrilled to teach technical courses on separations, reaction engineering, heat and mass transfer and unit operations labs, or more general chemical engineering seminars that introduce the field (as this is how I was pulled in). My teaching philosophy would be centered on the idea that students should come out of a course with an intuitive understanding of the subject that can be directly applied in the real-world. I would focus my lessons around questioning my students about how they would address problems in realistic situations.