2022 Annual Meeting

(289d) High Surface Area Guanidine Based Sorbents for CO2 Capture

DAC, while nascent, is a promising technology that offers a path to negative CO2 emissions and paves a path to remediating the anthropogenic impact on climate. DAC can complement point-source CO2 capture and storage (CCS), compensate for residual emissions that escape during point-source capture, and target distributed emissions. Traditionally, liquid sorbents like aqueous solutions containing potassium or sodium carbonate/hydroxide or alkanolamine solvents like monoethanolamine (MEA) or diethanolamine (DEA) have been used to capture CO2. Reasons including slow kinetics, loss of sorbent via evaporation, high regeneration temperatures hinder commercial viability of such technologies. Guanidine with its high amine availability has become a molecule of interest in recent years for CO2 sorption. In this work, we explore high surface area guanidine based polymeric sorbents that serve as high performance materials with excellent kinetics, sorption capacity, and fast and low-energy regeneration.

First, we examine the CO2 sorption potential of L-Arginine amino acid that has a guanidine group in the molecule. We show that the incorporation of L-Arginine onto high surface area poly(vinyl alcohol) (PVA) electrospun mats significantly improves sorption performance. Amino acids like L-Arginine, have the same functional group as alkanolamines (e.g., primary amines, and some also contain alcohol groups) and are potentially environmentally friendly. Amino acid solutions also have higher surface tension, lower volatility, better chemical and thermal stability, and exhibit similar or better CO2 absorption compared to alkanolamines. L-arginine (L-Arg), in particular, has shown excellent CO2 sorption capacity. By incorporating the amino acid L-arginine (L-Arg) onto a poly(vinyl alcohol) (PVA) nanofiber support, we created porous substrates with very high surface areas of L-Arg available for the sorption of CO2. The PVA-Arg nanofiber composites are flexible and show excellent passive DAC performance compared to bulk L-Arg. The nanofiber composites are fabricated via an electrospinning process using an aqueous polymer solution. After obtaining the nanofiber mats, they are physically crosslinked to improve resistance to water. Increasing L-Arg loading to 50 wt.% (with respect to PVA) improves sorption performance; however, loadings above 50 wt.% decrease the performance due to a reduction in porosity of the nanofiber composite. Higher ambient humidity levels also improve sorption performance significantly. The best performing nanofiber composite shows a maximum adsorption capacity of 542 µmol g-1 following 2 h of exposure to ambient, high humidity air that had a CO2 concentration of 445 ppm.

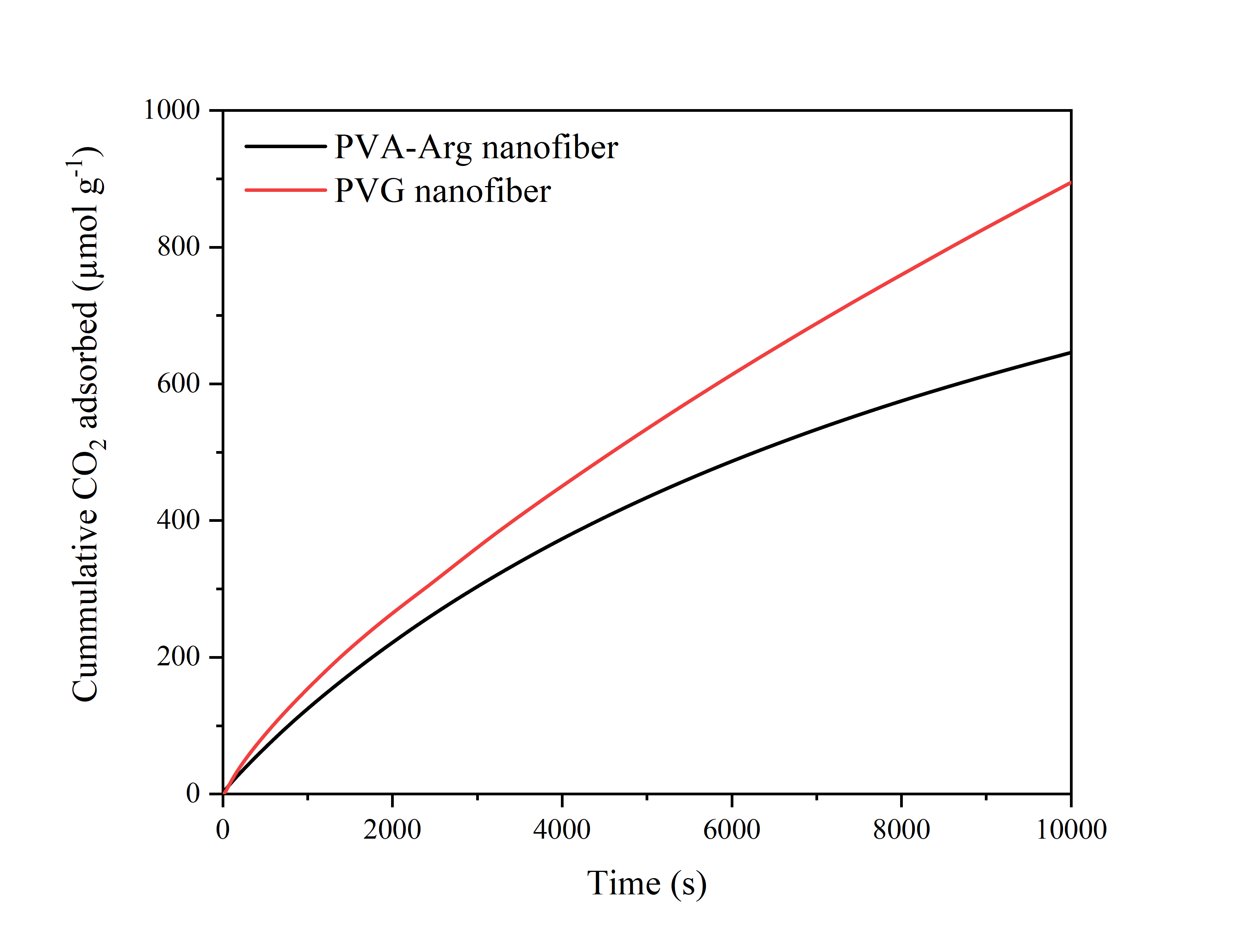

Secondly, we demonstrate the potential of poly(vinyl guanidine) (PVG) as a potential DAC sorbent. PVG is synthesized in three steps, starting with the free radical polymerization of vinyl formamide into poly(vinyl formamide). Poly(vinyl formamide) is then hydrolyzed using NaOH into poly(vinyl amine). The guanidine groups are introduced into the polymer via reaction with cyanamide under acidic conditions. PVG crosslinked with Gluteraldehyde (GA) is also synthesized to make the sorbent water resistant. Both the PVG and the GA crosslinked PVG show excellent DAC capabilities. Electrospinning the PVG into nanofibers further helps the material to attain fast kinetics and high sorption capacity on exposure to lab air. The PVG nanofibers also show excellent passive CO2 sorption capacities (attached Figure) of upto 703 µmol g-1 over a period of 2h while also displaying fast desorption kinetics. We further explore the role of form factor in improving the kinetics of sorption for PVG sorbents.

To simulate real world conditions, all testing of our sorbents were performed using lab air, simulating average wind speed conditions, with no packing of the material in the testing chamber. Thus, we successfully demonstrate passive CO2 sorption of these high surface area materials. Passive direct air capture of CO2 is required to make the process energy efficient and commercially viable. Thus, we successfully demonstrate the capabilities of high surface area guanidine polymeric materials for potential use in real world DAC applications.