2022 Annual Meeting

(145d) Optimal Design and Operation of Ternary Hybrid Dividing Wall Columns

Authors

In the previous work (Chia et al., 2022), the application of the H-DWC for the separation of minimum boiling binary azeotropic systems was explored, where the H-DWC was compared with three different hybrid distillation-pervaporation processes: a membrane system installed before a column (pervaporation-distillation, P-D structure), a membrane system installed after a column (distillation-pervaporation, D-P structure), and a membrane system installed between two columns (distillation-pervaporation-distillation, D-P-D structure). The comparison showed that D-P-D and H-DWC structures have similar performances with the least total annualized cost, compared to P-D and D-P, for the binary systems under consideration. The H-DWC is, however, superior to the other hybrid processes, including D-P-D, with increasing number of components in the feed, because with more components, more distillation columns will be required for the other hybrid processes. For the H-DWC, a single column with multiple walls is sufficient, i.e. only one column shell is needed, leading to reduced capital and/or operating cost for multicomponent systems. Energy savings can be achieved with the middle boiling component(s) freely distributed around the dividing wall(s), thus reducing the mixing effect within the column. To further explore the potential of the H-DWC, in this work, a H-DWC design for a ternary mixture with a minimum boiling binary azeotrope is proposed, and compared to the other three conventional hybrid processes (i.e. the P-D, D-P, and D-P-D structures), as well as to a standard extractive process.

The case study considered is the separation of a ternary mixture with a minimum boiling binary azeotrope. For the three conventional hybrid processes (D-P, P-D and D-P-D), an extra distillation column is required to remove either the lightest component A or the heaviest component C depending on the azeotrope. The proposed ternary H-DWC has two dividing walls and can separate all the three components in a single column shell.

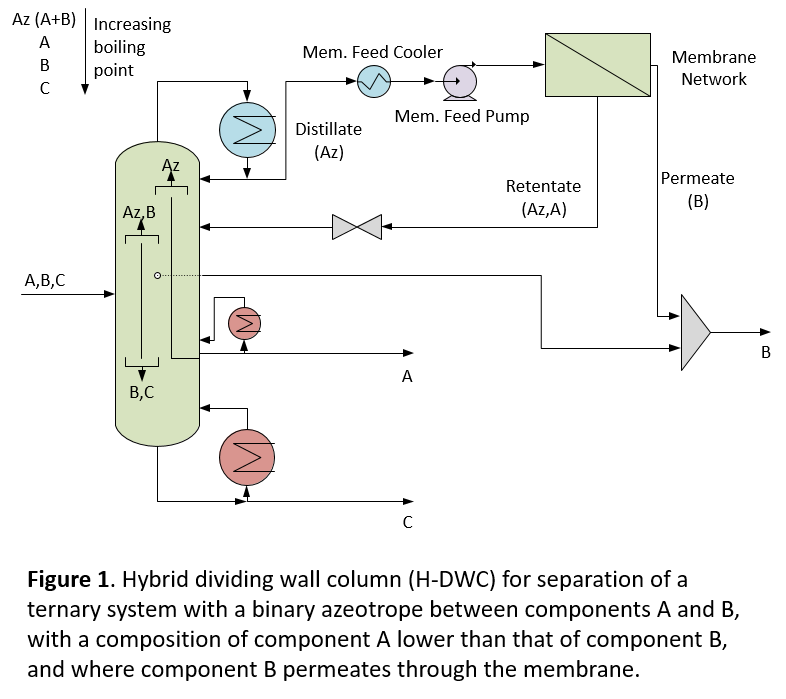

Figure 1 illustrates the process when the azeotrope is between the lightest two components A and B, and where it is also assumed that the concentration of component A is lower than the composition of component B, i.e. all of component A forms the azeotrope with most of component B. In addition, the figure assumes that component B permeates through the membrane. The remaining component B is freely distributed around the first wall in the column. In the illustration, the composition of component B is built up in the middle section of the column (i.e. section between the first and second dividing wall), and therefore high-purity component B can be collected there. The heaviest component C is purified at the bottom of the H-DWC. The azeotrope is processed in the membrane unit, where most of component B permeates through the membrane and is mixed with component B from the middle of the column. The retentate stream, here containing component A and some azeotrope, is recycled back to the column. Component A can be recovered from the H-DWC at the right side of the column (i.e. opposite of the feed entry) as only the azeotrope and component A are present in that location, and because component A is heavier than the A-B minimum boiling azeotrope.

For all the hybrid structures studied (P-D, D-P, D-P-D, and H-DWC), the membrane network considered the number of membrane stages in series, as well as the number of membrane modules in each membrane stage, as part of the optimisation (Chia and Sorensen, 2022). All the design and operating conditions are optimized simultaneously, i.e. number of stages, feed location and reflux ratio etc for the columns, and for the DWC also the location of the walls, the number of stages per section, and the liquid split between the walls. All simulations are performed in gPROMS Process (Process Systems Enterprise, 2021) and all the optimization variables (i.e. variables in the membrane network and the columns) are optimized simultaneously using Genetic Algorithm (Chia et al., 2021) coded in MATLAB (The MathWorks Inc., 2019).

This work will provide a comprehensive comparison between the separation and economic performances of the H-DWC, the three other distillation-pervaporation hybrid processes (D-P, P-D, D-P-D), as well as a traditional extractive distillation process, for the separation of a ternary system with a binary minimum boiling azeotrope between either A and B, or B and C, and for different feed composition conditions. The results will show that the HDWC can save both capital and/or operating cost due to its highly integrated design, thus showing its great potential for industrial applications.

References

Chia, D. N., Duanmu, F., and Sorensen, E. (2021). Optimal Design of Distillation Columns Using a Combined Optimisation Approach. In Turkay, M. and Gani, R., editors, 31st European Symposium on Computer Aided Process Engineering, pages 153â158. Elsevier B.V.

Chia, D. N., Duanmu, F., and Sorensen, E. (2022). Optimal Design of Hybrid Dividing Wall Columns for Azeotropic Separations, to be presented at Distillation & Absorption 2022, Toulouse, September 2022.

Chia, D. N. and Sorensen, E. (2022). Optimal Design of Hybrid Distillation/Pervaporation Processes, to be presented at PSE2021+, Kyoto, June 2022.

Lee, H.-Y., Li, S.-Y., and Chen, C.-L. (2016). Evolutional Design and Control of the Equilibrium-Limited Ethyl Acetate Process via Reactive DistillationâPervaporation Hybrid Configuration. Industrial & Engineering Chemistry Research, 55(32):8802â8817.

Process Systems Enterprise (2021). gPROMS Process version 2.2.