2020 Virtual AIChE Annual Meeting

(79f) Towards Rational Design of Curved Microreactors for Enhanced Mixing and Narrower Residence Time Distribution

Authors

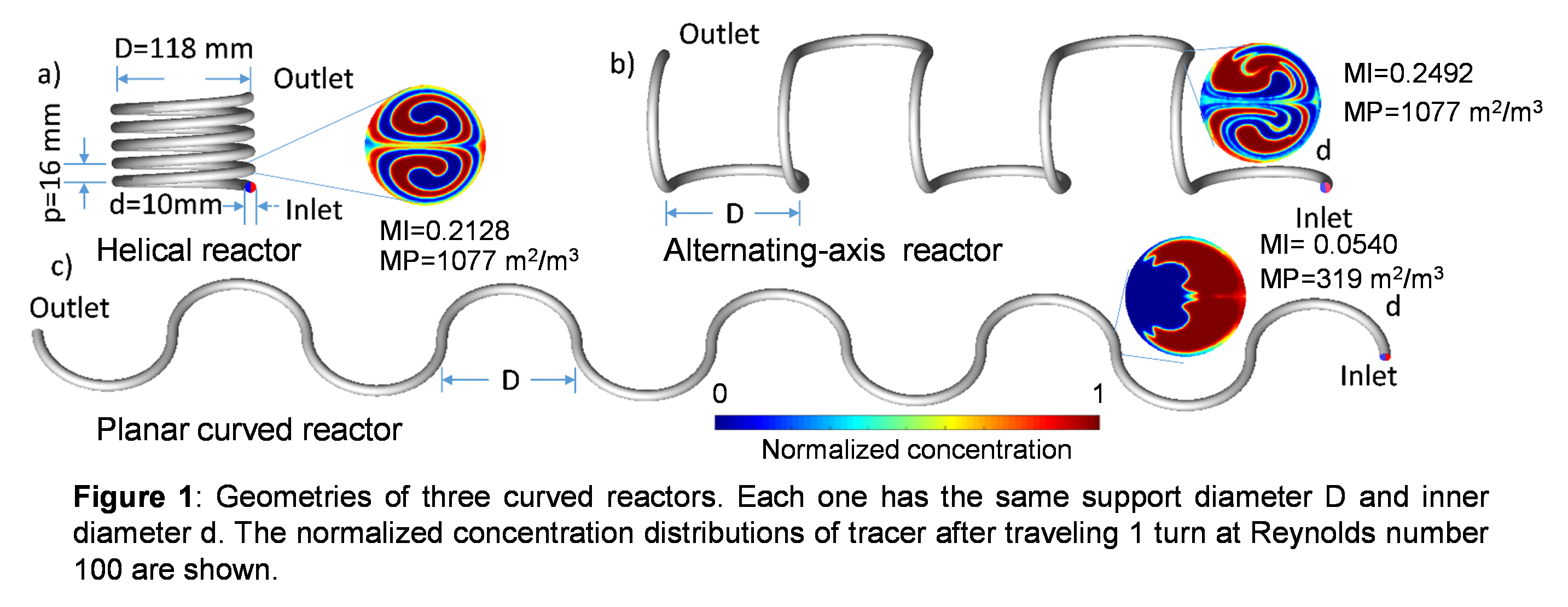

Further work reveals that mixing in the cross-section of the channel can be further enhanced by manipulating the direction of the curvature. Three different curved reactors shown in Figure 1 have been systematically analysed using computational fluid dynamic simulations (CFD). Backward particle tracking is adopted to simulate convection and the posterior Lagrangian transport model is solved to determine diffusion in order to reduce the effect of numerical diffusion (false diffusion), which arises from truncation errors associated to representing the fluid flow equations in discrete form (2). Mixing index (MI) and mixing potential (MP), the specific contact area between two streams(3), are used to quantify mixing.

After the same distance, the planar serpentine reactor shows the worst mixing potential due to the offset effect caused by opposite direction of the Dean vortices after two successive half circles. On the other hand, the alternating-axis reactor presents a higher level of mixing and narrower diffusion-free residence time distribution than the standard helical reactor when the Reynlds number is higher than 40.

References:

- Wu KJ, Bohan GM, Torrente-Murciano L. Synthesis of narrow sized silver nanoparticles in the absence of capping ligands in helical microreactors. Reaction Chemistry & Engineering. 2017;2(2):116-28.

- Matsunaga T, Lee HJ, Nishino K. An approach for accurate simulation of liquid mixing in a T-shaped micromixer. Lab on a Chip. 2013;13(8):1515-21.

- Bothe D, Stemich C, Warnecke HJ. Fluid mixing in a T-shaped micro-mixer. Chemical Engineering Science. 2006;61(9):2950-8.