2020 Virtual AIChE Annual Meeting

(759b) Identifying Opportunities for Mass Transfer in Chlorination and Cyclization Reactions

Authors

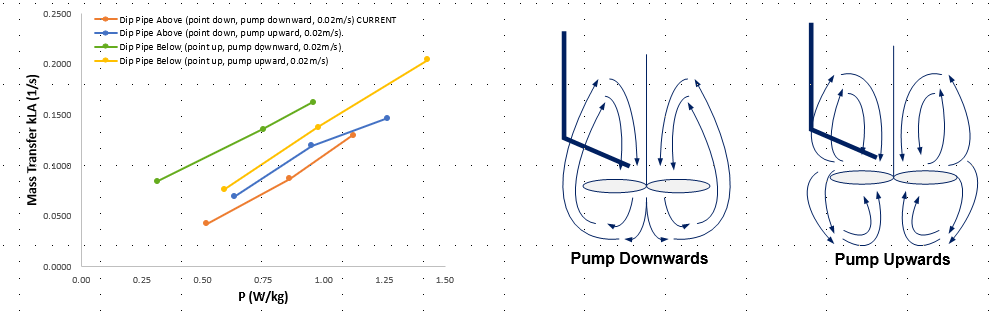

Various gas feed configurations were investigated and gas-liquid mass transfer of the chlorine gas was successfully improved. Moving the dip pipe from above the impeller to below the impeller resulted in 75% increase in mass transfer. Changing the pumping direction from downward to upward resulted in 20% increase in mass transfer by improving the energy dissipation through counter-current flow. Plant trials to implement these changes are planned for later this year.

Further downstream in the same process are cyclization reactors. The cyclization reactions in the process consist of two-phases with 90% less dense aqueous phase. We investigate the mixing power needed to improve the mass transfer between two immiscible liquids. If the reaction is mass transfer is limited, increased mass transfer can improve the cyclization reaction rate and lead to 2 to 3% yield improvements and over $2M per year in savings.

Droplet size at various mixing powers were investigated and it is shown that the droplet size can be further decreased by 2.5 times with increased mixing power. Furthermore, we have increased the mixing power and shown increases in reaction rate and yield on lab-scale, which confirm the reaction is mass transfer limited. This can also improve plant operations as higher temperatures can lead to lower selectivity- with increased reaction rates due to higher mixing power, the plant can run at lower temperatures and thereby reduce by-products and improve selectivity. An increase in mixing power is recommended to plant operations.