Over the two decades, the nanomaterials field has tremendously expanded to enable basic and applied research studies. In this regard, today there are approximately 300,000 nanomaterials, more than 840,000 articles published, and about 24,000,000 patents worldwide1. Some of these nanomaterials have reached industrial-scale production or implementation. For example, graphene sheets are industrially manufactured to produce sensors to detect the presence of contaminants in water2. Another example is TiO2 nanoparticles, which represent over 70% of total pigment production worldwide3. Despite the growing interest and potential of nanotechnology, most of these materials are still only produced at the lab scale. In the particular case of iron oxide paramagnetic nanoparticles, or magnetite, no reports are available about the production at the commercial scale for biomedical or pharmacological applications. This considerably limits the possibility of reaching commercial applications in the medical and diagnosis fields. This includes magnetic resonance contrast for high-resolution medical imaging, magnetic hyperthermia induction, diagnosis by targeted detection in cancer, detoxification of poison gases, and drug delivery4-5. To assure large-scale production the synthesis and purification of magnetite require high yields and low manufacturing costs. At the lab scale, magnetite can be synthesized by several different methods, including sol-gel6, sonochemical7, thermal decomposition7, and the widely used chemical co-precipitation8. Each of them leads to different particle size distribution, crystalline contents, surface morphology, and porosity6. Despite the low polydispersity, relatively high production yield, and uniform morphology of magnetite obtained via thermal decomposition or ultrasound impact, implementation at the large-scale is rather complicated and expensive. Alternatively, the sol-gel or co-precipitation methods show ease for implementation, relatively high-yields, and most importantly low associated costs. This suggests that these processes are well-suited for scaling-up8; however, they pose a major challenge regarding the dependency with respect to the mixing conditions, which in turn, control the growth and nucleation processes of magnetite8. These conditions need to be addressed in a dynamic manner during the process to assure that the obtained materials comply with the requirements in terms of particle size distribution and morphology. In the case of drug delivery applications, which are of interest to our research group, the average particle size should be around 100-200 nm.

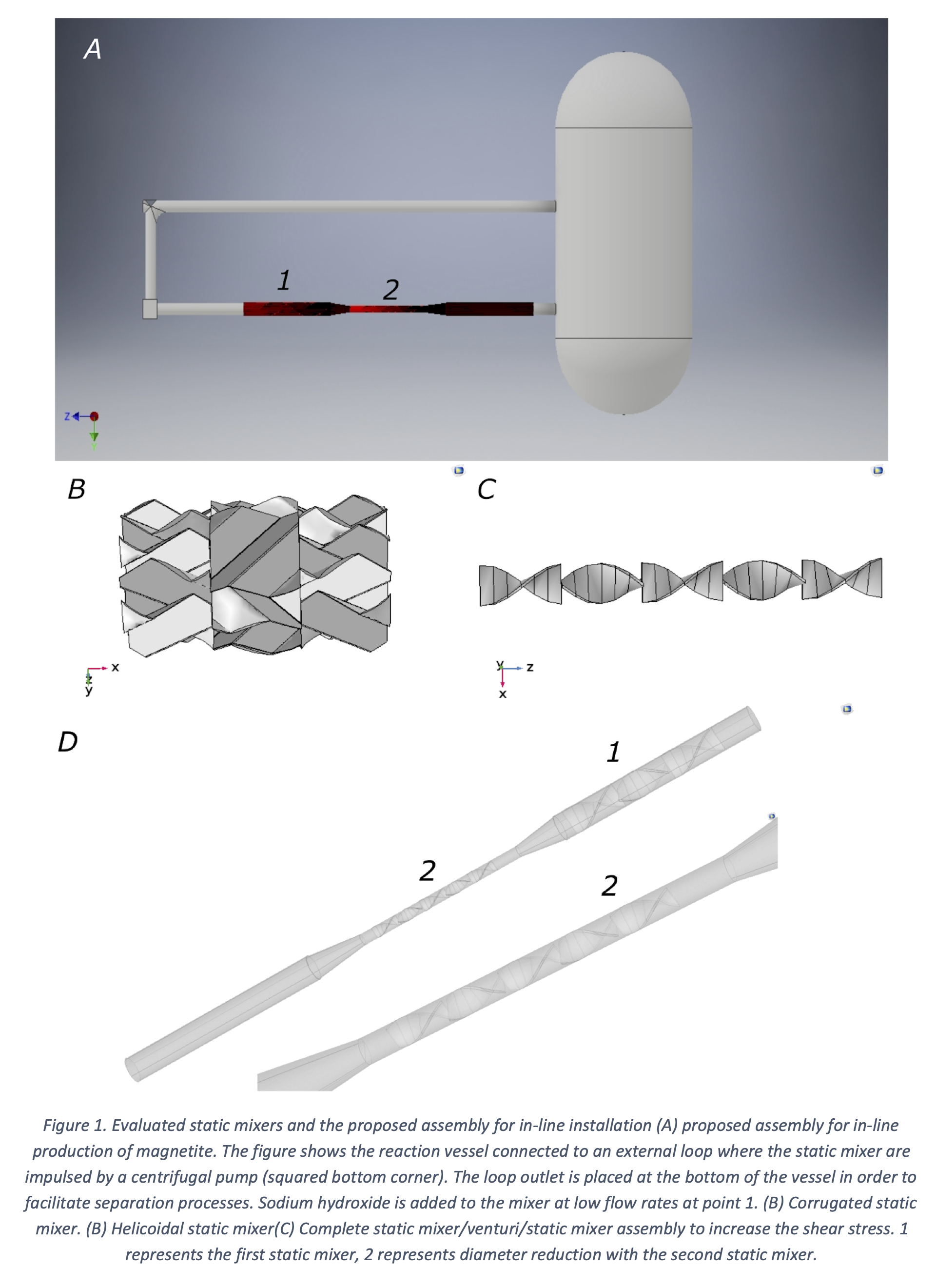

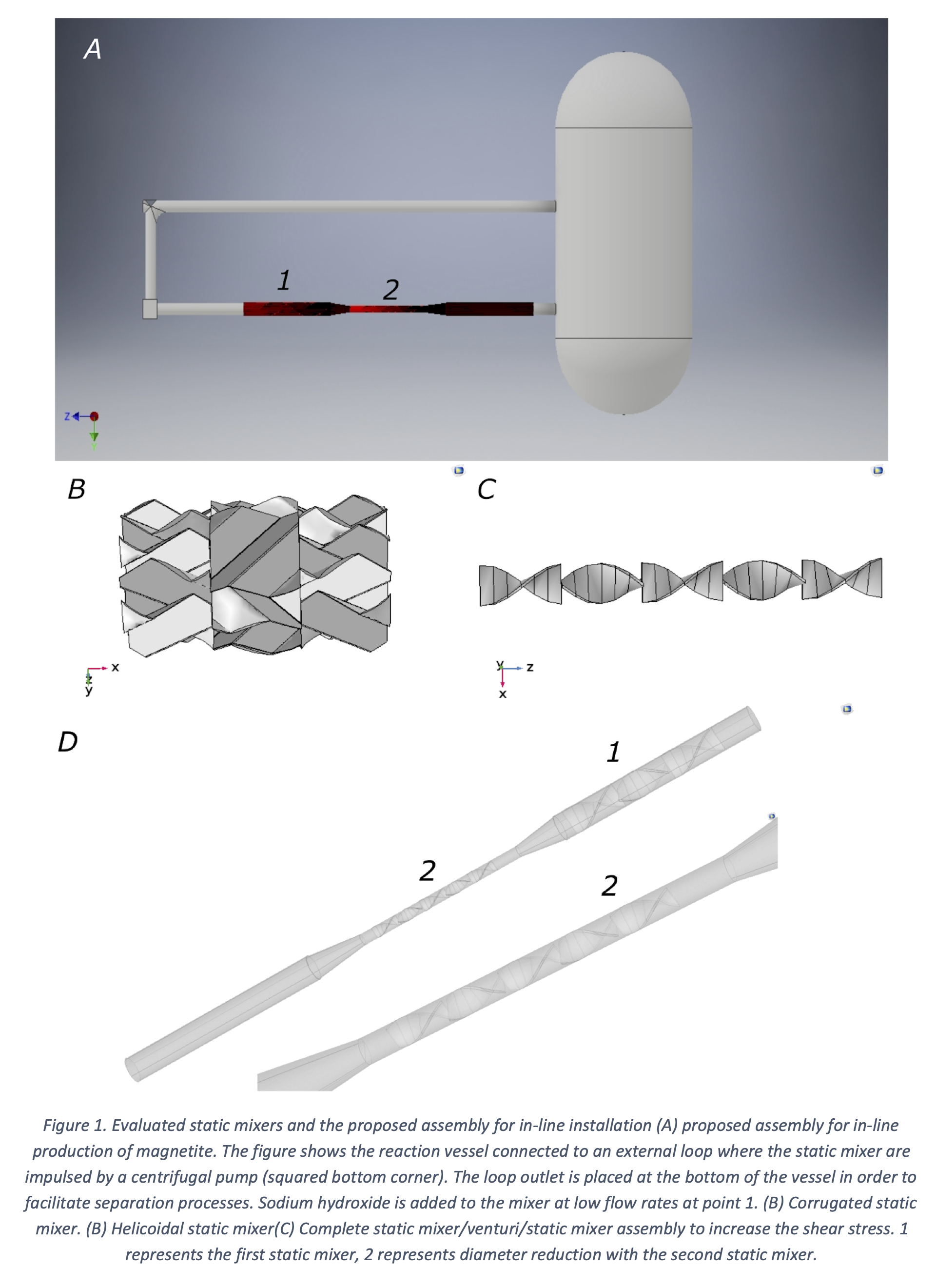

Here, we propose to tackle this major issue by maintaining proper mixing conditions via multiphase turbulent reacting flow during the synthesis of magnetite. The first step for the scaling-up of the co-precipitation method was to run the synthesis at the bench scale. In this case, the synthesis proceeded in a semi-batch mode of operation in a 3L stainless steel reactor equipped with a Rushton impeller, and a peristaltic pump to control the addition of the iron chlorides to the reaction mixture. The reaction started by adding the iron (II) and (III) chlorides to a sodium hydroxide solution (5M) at a rate of 10 mL/min while maintaining vigorous agitation at 600 RPM. The temperature was maintained at 90°C throughout the course of the reaction. The obtained material showed a wide size distribution that peaked at around 1 um, which fails to comply with the requirement for the intended application in drug delivery. According to our observations, this larger distribution appears to be related to poor mixing conditions where shear stress was insufficient. We propose to address this issue by locating a static mixer followed by a venturi system and a second static mixer on a recycling pipe that is constantly taking the reaction mixture and returning it after passing by the in-line mixing device (Figure 1). As a result, we hypothesize that this assembly should suffice to produce a turbulent reacting flow regime where growth and nucleation lead to the material with the required size. The proposed system was first evaluated in silico with the aid of COMSOL Multiphysics V.5.3. We considered two different types of mixers, one with a corrugated topology (Figure 2A) and second with a helicoidal one (Figure 2B). In COMSOL we implemented the chemical reactions and the transport of diluted species modules, which allowed us to estimate shear stress, input flows, pressure drop, and the proper location on the pipe. The computational domain of the complete assembly using the helicoidal mixer is shown in Figure 2C, which was discretized via about 600,000 free tetrahedral elements with a refinement in the edges prior to running the simulation to achieve convergence.

As the simulations indicated high-stress levels for the corrugated plates static mixer we, therefore, proceeded to manufacture such assembly. Experimental tests at the bench-scale confirmed a sharper particle size distribution with an average of about 120 nm. As opposed to the initial synthesis, the obtained material complies with the requirements of our application in drug delivery. Further tests at the pilot plant scale will be needed to adjust geometrical parameters of the mixers for evaluating yields and particle size distributions.

References:

1. Nano â A comprehensive nanotechnology database by Nature Research. Available at: https://nano.nature.com/?gclid=CjwKCAjwg6b0BRBMEiwANd1_SKvZ8lVUeaTdZsvd… April 2020)

2. Arfin, T. & Tarannum, A. Engineered nanomaterials for industrial application: An overview. in Handbook of Nanomaterials for Industrial Applications 127â134 (Elsevier, 2018). doi:10.1016/B978-0-12-813351-4.00006-7

3. Larue, C. et al. Fate of pristine TiO2 nanoparticles and aged paint-containing TiO2 nanoparticles in lettuce crop after foliar exposure. J. Hazard. Mater. 273, 17â26 (2014).

4. Varadan, V. K. Nanomedicine : design and applications of magnetic nanomaterials, nanosensors, and nanosystems. TA - TT - (Wiley, 2008).

5. Latorre, M. & Rinaldi, ; Carlos. Applications of Magnetic Nanoparticles in Medicine: Magnetic Fluid Hyperthermia. prhsj.rcm.upr.edu (2009).

6. Edebali, S., Oztekin, Y. & Arslan, G. Metallic engineered nanomaterial for industrial use. in Handbook of Nanomaterials for Industrial Applications 67â73 (Elsevier, 2018). doi:10.1016/B978-0-12-813351-4.00004-3

7. Nee Koo, K., Fauzi Ismail, A., Hafiz Dzarfan Othman, M., Rahman, M. A. & Zhong Sheng, T. Preparation and characterization of superparamagnetic magnetite (Fe3O4) nanoparticles: A short review. / Malaysian Journal of Fundamental and Applied Sciences 15, (2019).

8. Paliwal, R., Jayachandra Babu, R. & Palakurthi, S. Nanomedicine Scale-up Technologies: Feasibilities and Challenges. doi:10.1208/s12249-014-0177-9