2020 Virtual AIChE Annual Meeting

(365g) Integrating Process Design and Materials Genomics for Energy Efficient Adsorption-Based Capture Technologies

Authors

In this work, we integrate recent developments in Material Science and Materials Genomics,3in which we generate in silico millions of candidate materials for CO2capture, with process design and techno-economic and environmental analyses. The lack of such integration has been identified as one of the key bottlenecks that limit the prospect of novel materials for carbon capture technologies to reach the market. This study is carried out within the framework of the PrISMa project (http://www.act-ccs.eu/prisma), which is an international effort that aims to accelerate the transition of energy and industrial sectors to a low-carbon economyby developinga technology platform to tailor-make cost-efficient carbon capture solutionsfor a range of different CO2sources and CO2use/destinations.Our aimed technology platform will allow us to tailor-make carbon capture solutions in terms of an effective carbon price (ECP) that makes a particular process economically viable. To achieve that, we integrate materials and process design, supported by computational materials genomic approaches, machine-learning, high-throughput material synthesis and characterization, device-performance testing, value chain analysis and systematic process design.

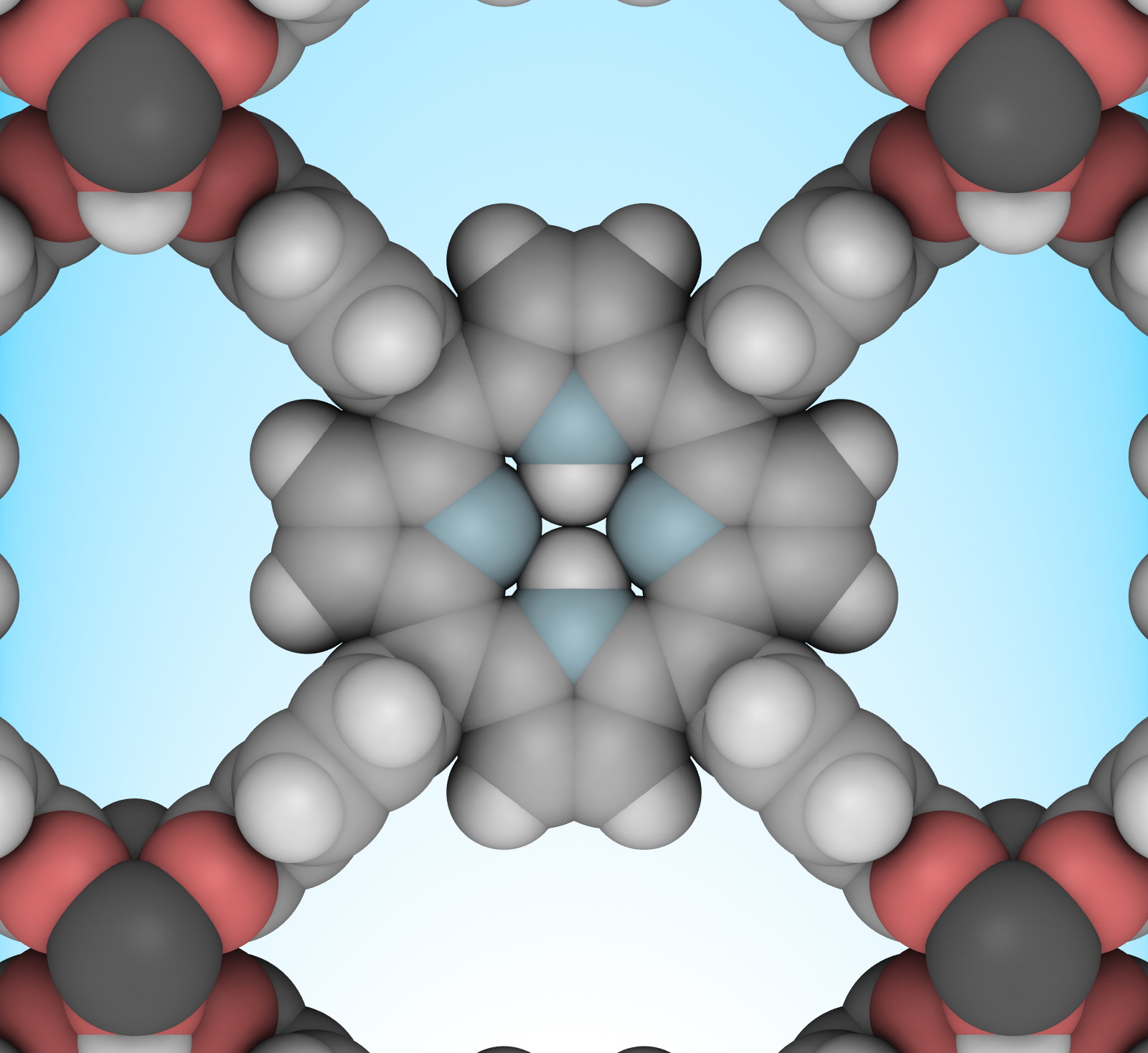

Through this integration, we aim to change the paradigm on how novel materials are developed for chemical engineering applications. Some recent results4from the PrISMa collaboration involved the design of a metal organic framework that can capture CO2in wet flue gasses (see Figure 1). As a similar approach can be developed for other separations, we expect the impact of this work in terms of the potential to decrease the time to market for novel materials to go beyond carbon capture applications.

Acknowledgements

The PrISMa Project (No 299659) is funded through the ACT programme (Accelerating CCS Technologies, Horizon2020 Project No 294766). Financial contributions made from: Department for Business, Energy & Industrial Strategy (BEIS) together with extra funding from NERC and EPSRC Research Councils, United Kingdom; The Research Council of Norway, (RCN), Norway; Swiss Federal Office of Energy (SFOE), Switzerland; and US-Department of Energy (US-DOE), USA, are gratefully acknowledged. Additional financial support from TOTAL and Equinor is also gratefully acknowledged.

References

[1]B. Smit and S. Garcia, Carbon capture and storage: making fossil fuels great again?Europhys. News 51(2), 20 (2020) http://dx.doi.org/10.1051/epn/2020203

[2]H. Furukawa, K. E. Cordova, M. O'Keeffe, and O. M. Yaghi, The Chemistry and Applications of Metal-Organic FrameworksScience 341(6149), 974 (2013) http://dx.doi.org/10.1126/Science.1230444

[3]P. G. Boyd, Y. J. Lee, and B. Smit, Computational development of the nanoporous materials genomeNat Rev Mater 2(8), 17037 (2017) http://dx.doi.org/10.1038/natrevmats.2017.37

[4]P. G. Boyd, A. Chidambaram, E. Garcia-Diez, C. P. Ireland, T. D. Daff, R. Bounds, A. Gladysiak, P. Schouwink, S. M. Moosavi, M. M. Maroto-Valer, J. A. Reimer, J. A. R. Navarro, T. K. Woo, S. Garcia, K. C. Stylianou, and B. Smit, Data-driven design of metal-organic frameworks for wet flue gas CO2 captureNature 576(7786), 253 (2019) http://dx.doi.org/10.1038/s41586-019-1798-7

Figure 1: A molecular representation of the carbon capture material Al-PMOF (picture by Mohamad Moosavi and Kevin Jablonka; iRASPA software was used for visualisation)