2020 Virtual AIChE Annual Meeting

(21d) Innovative Design of Semi Batch Reactor Used for Catalytic Liquid Phase Epoxidation of Propylene to Propylene Oxide

Author

Waheed. A. Almasry - Presenter, King Saud University

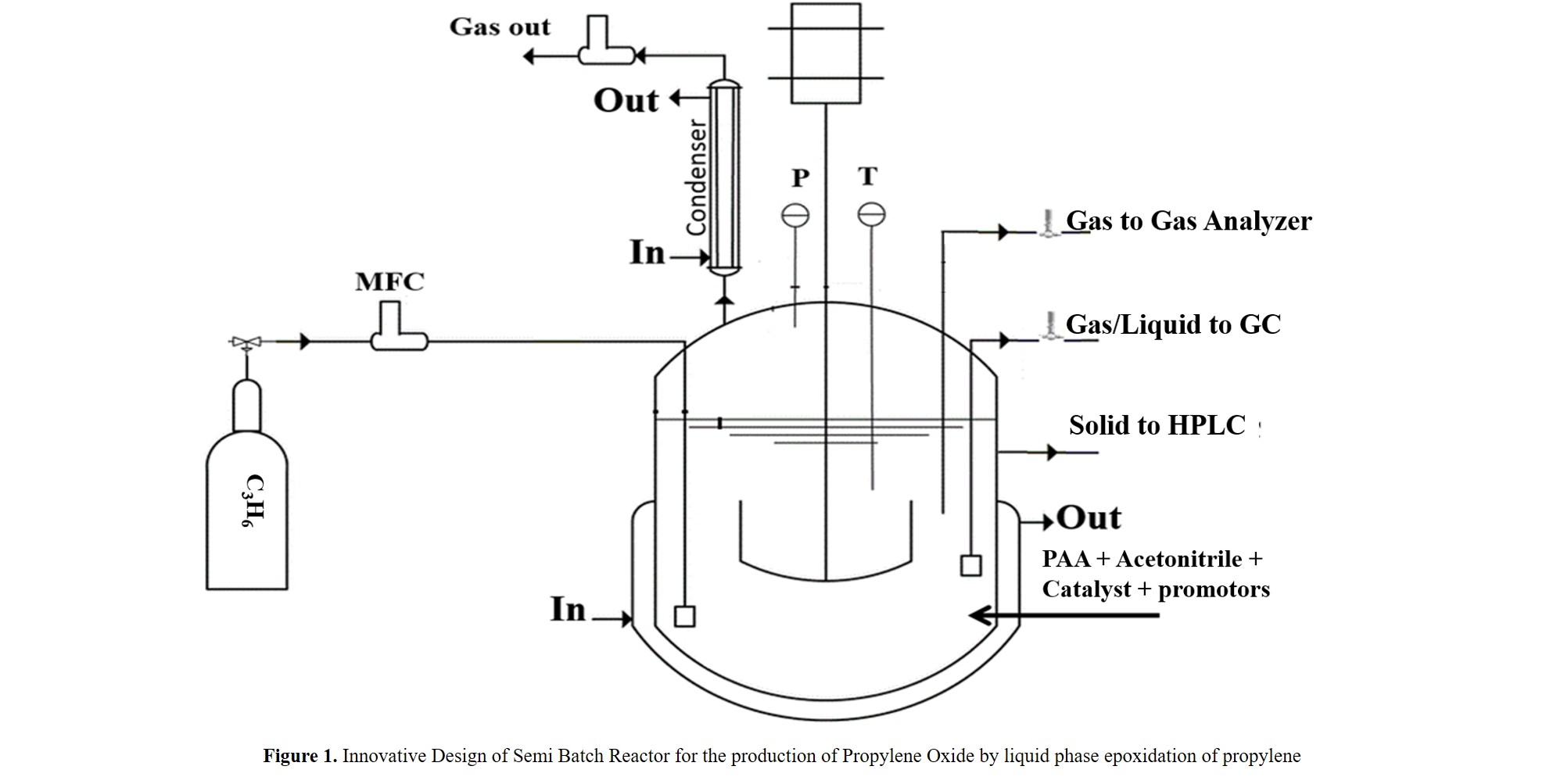

Compare to conventional process, CO2 free Propylene Oxide with high selectivity under mild reaction conditions was produced by liquid phase epoxidation of propylene using Au/TiO2 catalysts where Peracetic acid (PAA) was used as oxidant. Au/TiO2 catalyst (Au (1 wt.%) supported on TiO2) was prepared by conventional deposition-precipitation method with NaOH (DP NaOH) followed by washing, drying and calcination in air. Thermal treatment of Au/TiO2 was carried out at 450 oC under 0.05 mTorr. A small amount of Au/TiO2 catalyst was taken from the untreated and thermally treated Au/TiO2 and the both kinds of catalysts were treated with plasma sputtering at room temperature. The catalytic activity of all the samples were tested using an alternative liquid phase propylene epoxidation route to produce Propylene Oxide under mild operating conditions where CO2 formation is completely suppressed. Since it is liquid phase epoxidation process therefore, it is a safe process as well. Therefore, by using an alternative route for the production of Propylene Oxide, three following main advantages are deliberated: first, zero CO2 production as a byproduct, second, a safe process and third, an improved process efficiency (high selectivity). For the above said process, an innovative designed semi batch reactor shown in figure 1 was used successfully. The results showed >95% selectivity of the desired product.

Keywords:

Liquid phase epoxidation, propylene oxide, Au/TiO2 catalyst, thermal and plasma treatment, semi batch reactor